In the world of electronics, ensuring the reliability of printed circuit boards (PCBs) is crucial for the performance and longevity of devices. While temperature has long been a primary focus for monitoring PCB health, other environmental factors play a significant role in PCB reliability. Environmental sensors, including temperature and humidity sensors, are powerful tools for detecting conditions that can lead to issues like corrosion and board failure. In this blog, we’ll explore how using environmental sensors for PCB reliability can prevent costly damages and improve overall performance. We'll dive into the importance of monitoring beyond just heat, the role of various sensors, and practical steps to implement them for PCB corrosion prevention.

Why Environmental Sensors Matter for PCB Reliability

PCBs are the backbone of electronic devices, and their failure can result in system downtime, costly repairs, or even safety hazards in critical applications like medical or aerospace systems. Environmental conditions such as high humidity, temperature fluctuations, and exposure to contaminants can degrade PCB materials, cause corrosion, and disrupt signal integrity. For instance, studies have shown that humidity levels above 60% can accelerate corrosion on PCB surfaces, especially when combined with contaminants like dust or flux residue. This is where environmental sensors for PCB monitoring come into play, offering real-time data to prevent damage before it occurs.

By integrating sensors that track temperature, humidity, and other factors, engineers can gain insights into the conditions affecting their boards. This proactive approach helps in designing more robust systems and implementing protective measures, ensuring long-term PCB reliability.

The Role of Temperature Sensors in PCB Protection

Temperature sensors are among the most commonly used tools for monitoring PCB health. Excessive heat can cause thermal stress, leading to component failure or solder joint cracks. For example, operating a PCB beyond its thermal limit—often around 85°C to 105°C for standard materials like FR-4—can reduce its lifespan by up to 50%. Temperature sensors help detect hotspots on the board, allowing engineers to adjust cooling mechanisms or redesign layouts for better heat dissipation.

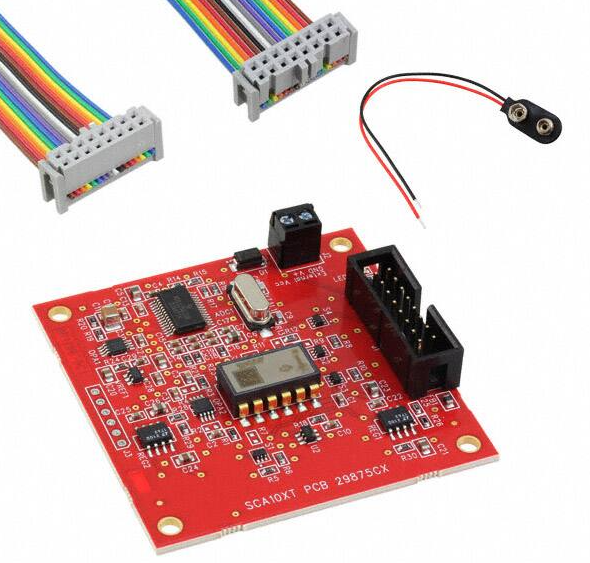

Modern temperature sensors, such as thermocouples or digital sensors with I2C interfaces, offer high accuracy, often within ±0.5°C. These devices can be embedded near critical components to provide real-time data, enabling automated systems to shut down or reduce power when temperatures exceed safe thresholds. By addressing thermal issues early, temperature sensors play a vital role in enhancing PCB reliability.

Humidity Sensors: A Key to PCB Corrosion Prevention

While temperature is critical, humidity is often an overlooked factor that can silently damage PCBs. High humidity levels can lead to moisture accumulation on the board, creating a conductive path that causes short circuits or corrosion of metal traces. Research indicates that environments with relative humidity (RH) above 70% significantly increase the risk of electrochemical migration, a process where metal ions move between traces, leading to failures.

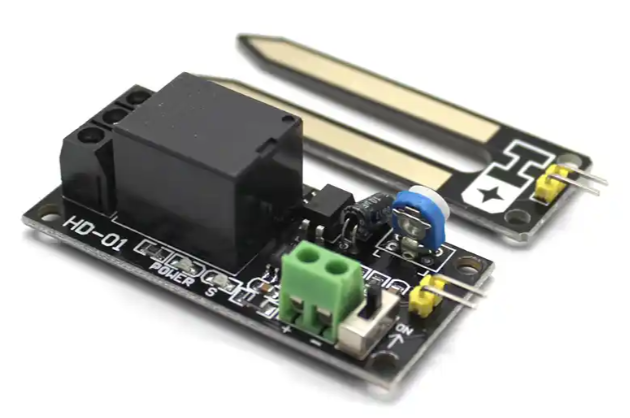

Humidity sensors for PCBs are designed to detect moisture levels in the surrounding environment. Capacitive humidity sensors, for instance, measure changes in capacitance caused by moisture absorption, offering accuracy within ±2% RH. By monitoring humidity, engineers can implement protective measures like conformal coatings or enclosures to shield boards from moisture. This is especially important for applications in humid climates or industries like marine and automotive, where exposure to moisture is common.

Combining Temperature and Humidity Sensors for Comprehensive Monitoring

While temperature and humidity sensors are powerful on their own, combining them provides a more complete picture of the environmental conditions affecting PCB reliability. For example, high humidity combined with elevated temperatures can accelerate corrosion rates exponentially. A study on atmospheric corrosion found that a 10°C rise in temperature alongside 80% RH can double the corrosion rate of copper traces on a PCB.

Integrated environmental sensors for PCB monitoring are now available, combining temperature and humidity readings into a single compact device. These sensors often connect via standard interfaces like SPI or I2C, making them easy to integrate into existing designs. By collecting data on both parameters, engineers can correlate environmental conditions with PCB performance, identifying potential risks before they lead to failure.

Other Environmental Sensors for Enhanced PCB Protection

Beyond temperature and humidity, other environmental sensors can further improve PCB reliability by detecting additional threats. Let’s explore a few key types:

- Pressure Sensors: Changes in atmospheric pressure can indicate potential issues in sealed enclosures, such as leaks that allow moisture or dust ingress. Monitoring pressure helps maintain the integrity of protective environments for PCBs.

- Gas Sensors: In industrial settings, exposure to corrosive gases like hydrogen sulfide (H2S) can degrade PCB surfaces. Gas sensors can detect harmful substances in the air, triggering alerts or ventilation systems to minimize damage.

- Dust and Particulate Sensors: Dust accumulation on PCBs can trap moisture and create conductive paths, leading to short circuits. Particulate sensors help detect contamination levels, prompting timely cleaning or filtration measures.

By incorporating a range of environmental sensors for PCB protection, engineers can address multiple failure modes, ensuring boards remain reliable even in harsh conditions.

Practical Applications of Environmental Sensors in PCB Design

Environmental sensors are invaluable across various industries where PCB reliability is non-negotiable. Here are some real-world applications where these sensors make a significant impact:

- Automotive Electronics: Vehicles operate in diverse conditions, from freezing winters to humid summers. Sensors monitoring temperature and humidity help prevent failures in critical systems like engine control units (ECUs), where a single failure could compromise safety.

- Industrial Automation: Factory environments often expose PCBs to dust, heat, and moisture. Environmental sensors enable predictive maintenance, reducing downtime by alerting engineers to potential issues before they escalate.

- Consumer Electronics: Devices like smartphones and wearables face daily exposure to varying conditions. Embedding sensors during design helps manufacturers test and validate products for durability under real-world scenarios.

In each of these cases, environmental sensors provide actionable data, allowing for better design decisions and improved PCB corrosion prevention strategies.

How to Integrate Environmental Sensors into PCB Designs

Integrating environmental sensors into PCB designs requires careful planning to ensure accuracy and effectiveness. Here are some practical steps to follow:

- Select the Right Sensors: Choose sensors based on the specific environmental factors most relevant to your application. For instance, prioritize humidity sensors for tropical environments and temperature sensors for high-power systems.

- Placement Matters: Position sensors close to critical components or areas prone to environmental stress. Avoid placing them near heat sources that could skew readings, unless monitoring heat is the goal.

- Data Integration: Use microcontrollers or IoT platforms to collect and analyze sensor data in real time. This allows for automated responses, such as activating cooling fans when temperature thresholds are exceeded.

- Protect the Sensors: Ensure sensors are shielded from direct exposure to contaminants or physical damage while still allowing them to measure environmental conditions accurately.

- Testing and Calibration: Regularly calibrate sensors to maintain accuracy. Test the system under simulated harsh conditions to validate sensor performance and PCB reliability.

By following these steps, you can seamlessly incorporate environmental sensors for PCB monitoring, enhancing the overall durability of your designs.

Benefits of Using Environmental Sensors for PCB Reliability

The advantages of using environmental sensors extend beyond just preventing failures. Here are some key benefits:

- Cost Savings: Early detection of environmental threats reduces the need for expensive repairs or replacements. For instance, addressing humidity issues before corrosion sets in can save thousands in rework costs.

- Improved Product Lifespan: By maintaining optimal operating conditions, sensors help extend the life of PCBs, ensuring devices perform reliably for years.

- Enhanced Safety: In critical applications, preventing PCB failures through sensor monitoring can avoid catastrophic outcomes, protecting both users and equipment.

- Data-Driven Design: Sensor data provides valuable insights for future designs, helping engineers create more robust and resilient PCBs tailored to specific environments.

Challenges and Solutions in Implementing Environmental Sensors

While environmental sensors offer immense value, there are challenges to consider during implementation. One common issue is the added cost and complexity of integrating sensors into compact PCB designs. To address this, opt for miniaturized sensors with low power consumption, which are widely available for embedded applications.

Another challenge is ensuring sensor accuracy over time, as exposure to harsh conditions can degrade performance. Regular calibration and using sensors with built-in compensation for temperature or humidity drift can mitigate this problem. Finally, data overload from multiple sensors can complicate analysis. Leveraging software tools or cloud-based platforms can help process and visualize data effectively, making it easier to act on insights.

Future Trends in Environmental Sensors for PCB Reliability

The field of environmental sensors for PCB monitoring is evolving rapidly, driven by advancements in IoT and smart manufacturing. Future trends include the development of printed sensors, which can be directly integrated onto PCBs during fabrication for ultra-low-cost monitoring. Additionally, AI-powered analytics will enhance the ability to predict failures by analyzing sensor data patterns, offering even greater protection against environmental threats.

Another exciting development is the rise of eco-friendly, biodegradable sensors for sustainable electronics. These innovations aim to reduce electronic waste while maintaining high reliability standards, aligning with global efforts to create greener technologies.

Conclusion: Building Resilient PCBs with Environmental Sensors

Ensuring PCB reliability requires more than just monitoring temperature; it demands a comprehensive approach to understanding and mitigating environmental risks. By leveraging environmental sensors for PCB protection, including temperature and humidity sensors, engineers can prevent issues like corrosion, thermal stress, and moisture damage. These tools provide real-time insights, enabling proactive measures that save costs, improve safety, and extend product lifespans.

Whether you’re designing for automotive, industrial, or consumer applications, integrating environmental sensors is a smart investment in durability and performance. As technology advances, these sensors will become even more accessible and powerful, paving the way for smarter, more resilient electronics. Start exploring the potential of environmental sensors today to build PCBs that stand the test of time and environment.

ALLPCB

ALLPCB