When it comes to designing and manufacturing printed circuit boards (PCBs), thickness is a critical factor that can impact performance, durability, and suitability for specific applications. While 1.6mm is often considered the industry standard for PCB thickness, there’s a wide range of standard thicknesses available, each with unique benefits and uses. In this comprehensive guide, we’ll explore the full spectrum of standard PCB thicknesses, dive into a detailed PCB thickness chart, and discuss their applications, material properties, bending strength, and flexibility. Whether you’re an engineer, designer, or manufacturer, this article will help you make informed decisions for your next project.

Why PCB Thickness Matters in Design and Manufacturing

PCB thickness directly affects the mechanical stability, electrical performance, and thermal management of a circuit board. Choosing the right thickness ensures that your PCB can withstand physical stress, handle electrical loads, and fit within the constraints of your device. While 1.6mm is a common choice due to its balance of strength and versatility, other thicknesses ranging from as thin as 0.2mm to as thick as 3.2mm are widely used for specialized applications. Understanding the range of standard PCB thicknesses and their specific uses can optimize your design for performance and cost-efficiency.

In the sections below, we’ll break down the standard thicknesses, provide a practical PCB thickness chart, and explore how factors like material properties, bending strength, and flexibility influence the choice of thickness for different projects.

Standard PCB Thickness Chart: A Quick Reference Guide

Before diving into the details, let’s start with a clear overview of standard PCB thicknesses. The table below serves as a handy PCB thickness chart, outlining common thicknesses, their typical layer counts, and primary applications.

| Thickness (mm) | Common Layer Count | Typical Applications |

|---|---|---|

| 0.2 - 0.4 | 1-2 | Flexible PCBs, wearable devices, compact electronics |

| 0.6 - 0.8 | 2-4 | Lightweight consumer electronics, small gadgets |

| 1.0 - 1.2 | 4-6 | Mid-range devices, industrial controls |

| 1.6 | 4-8 | General-purpose electronics, automotive systems |

| 2.0 - 2.4 | 8-12 | High-power applications, server boards |

| 3.0 - 3.2 | 12+ | Heavy-duty industrial equipment, military hardware |

This chart provides a starting point for understanding standard PCB thickness uses. However, the right thickness for your project depends on several factors, including the intended application, electrical requirements, and mechanical constraints. Let’s explore these factors in detail.

Understanding the Range of Standard PCB Thicknesses

Standard PCB thicknesses typically range from 0.2mm to 3.2mm, with increments that align with manufacturing capabilities and design needs. Each thickness serves a specific purpose, balancing factors like weight, durability, and electrical performance. Here’s a closer look at the most common options:

Ultra-Thin PCBs: 0.2mm to 0.4mm

Ultra-thin PCBs are often used in flexible or compact designs where space is at a premium. With thicknesses as low as 0.2mm, these boards are ideal for wearable technology, medical devices, and miniaturized electronics. They usually have 1-2 layers and are made from flexible materials like polyimide to enhance PCB flexibility. However, their thin profile limits their bending strength, making them less suitable for applications requiring high mechanical stress.

Thin PCBs: 0.6mm to 0.8mm

Boards in the 0.6mm to 0.8mm range are lightweight and often used in small consumer electronics like smartphones and tablets. These thicknesses support 2-4 layers and offer a good balance between compactness and durability. While they provide better bending strength than ultra-thin boards, they still require careful handling to avoid damage during assembly or use.

Mid-Range PCBs: 1.0mm to 1.2mm

Mid-range thicknesses of 1.0mm to 1.2mm are suitable for applications that need moderate durability and layer counts of 4-6. These boards are often found in industrial controls and communication devices. They offer improved mechanical stability compared to thinner options, making them a versatile choice for many projects.

Standard PCBs: 1.6mm

The 1.6mm thickness is widely regarded as the industry standard due to its excellent balance of strength, cost, and compatibility with most manufacturing processes. Supporting 4-8 layers, these boards are used in a vast array of applications, from automotive electronics to household appliances. Their bending strength is sufficient for most general-purpose uses, and they can handle moderate electrical loads with ease.

Thicker PCBs: 2.0mm to 2.4mm

Thicker boards in the 2.0mm to 2.4mm range are designed for high-power applications where additional layers (8-12) and enhanced thermal management are needed. These thicknesses are common in server motherboards and power supply units. Their increased thickness improves bending strength, making them more resistant to physical stress and vibration.

Heavy-Duty PCBs: 3.0mm to 3.2mm

At the upper end of the spectrum, 3.0mm to 3.2mm PCBs are built for extreme conditions. With support for 12 or more layers, these boards are used in military hardware, heavy industrial equipment, and aerospace systems. Their robust bending strength ensures reliability in harsh environments, though their weight and cost are significantly higher than thinner options.

PCB Material Properties and Their Impact on Thickness Choice

The choice of PCB thickness is closely tied to the material properties of the board. Different materials offer varying levels of durability, thermal conductivity, and electrical performance, all of which influence the optimal thickness for a given application. Let’s explore some key PCB material properties:

Dielectric Constant and Impedance Control

The dielectric constant of a PCB material affects signal speed and impedance. For high-frequency applications, such as RF circuits, thinner boards (0.6mm to 1.0mm) made from materials with low dielectric constants (like PTFE) are preferred to minimize signal loss. For example, a 0.8mm board with a dielectric constant of 2.2 can maintain controlled impedance at 50 ohms, which is critical for high-speed data transmission.

Thermal Conductivity

Thermal management is crucial in high-power applications. Thicker boards (2.0mm to 3.2mm) made from materials with high thermal conductivity, such as metal-core substrates, are better at dissipating heat. This is why thicker PCBs are often used in LED lighting systems and power converters, where heat buildup can degrade performance.

Mechanical Strength and Durability

Materials like FR-4, a common fiberglass-epoxy laminate, provide good mechanical strength for standard thicknesses like 1.6mm. However, for ultra-thin boards (0.2mm to 0.4mm), flexible materials like polyimide are used to maintain PCB flexibility while sacrificing some durability. Understanding the trade-offs between material strength and thickness helps ensure the board can withstand the physical demands of its environment.

PCB Bending Strength and Flexibility: Key Considerations

Two critical mechanical properties to consider when selecting PCB thickness are bending strength and flexibility. These factors determine how well a board can handle stress and adapt to specific design requirements.

PCB Bending Strength

Bending strength refers to a PCB’s ability to resist deformation under mechanical stress. Thicker boards naturally have higher bending strength, making them ideal for applications exposed to vibration or physical impact. For instance, a 2.4mm PCB used in an automotive control unit can withstand constant engine vibrations without cracking, while a 0.4mm board would likely fail under similar conditions.

In contrast, thinner boards have lower bending strength and are more prone to damage. This is why ultra-thin PCBs are typically used in static or low-stress environments, such as inside a smartwatch, where minimal mechanical force is applied.

PCB Flexibility

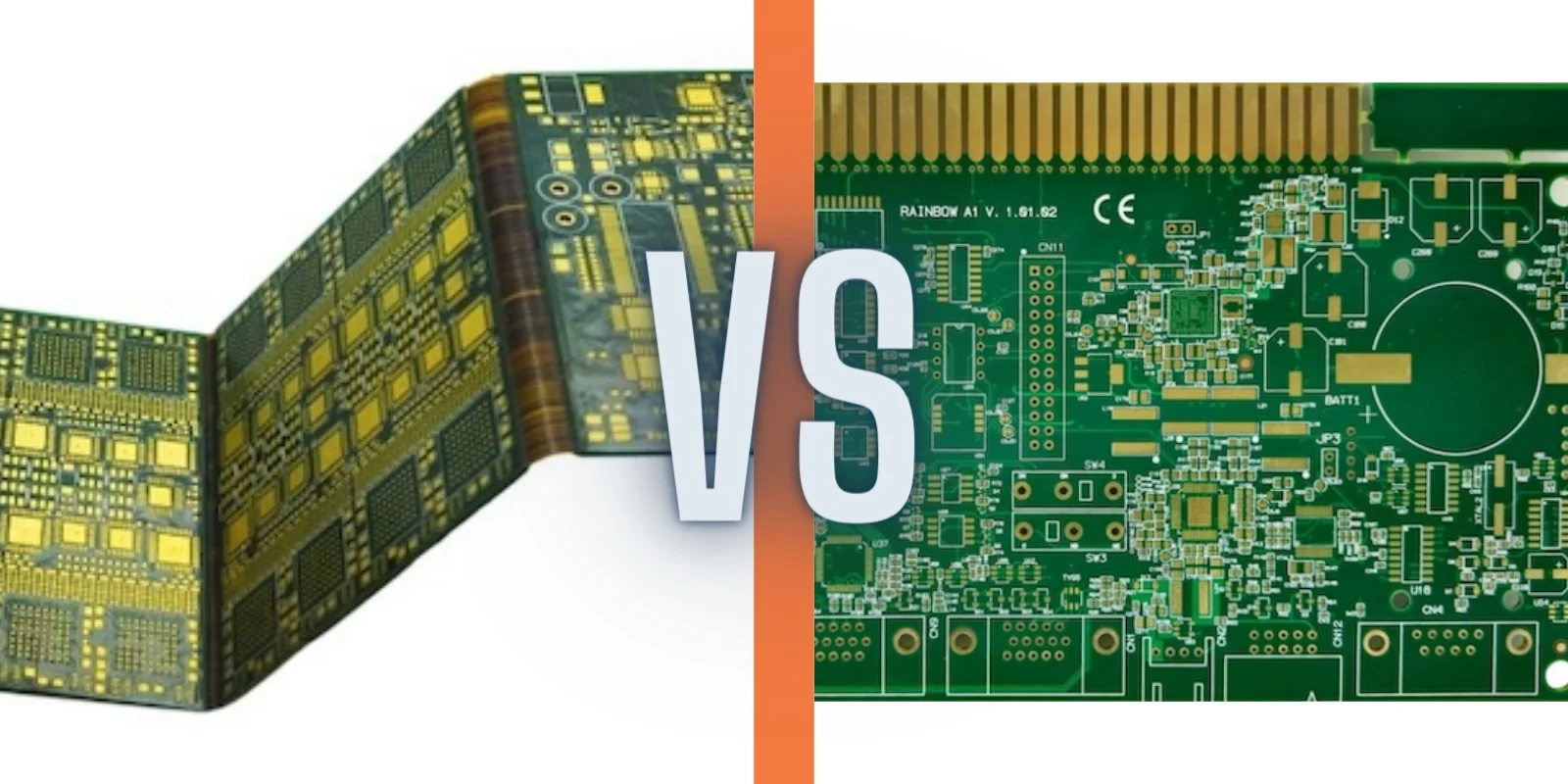

Flexibility is essential for applications requiring the PCB to bend or conform to a specific shape. Flexible PCBs, often ranging from 0.2mm to 0.4mm in thickness, are designed to bend repeatedly without breaking. These boards are made from materials like polyimide and are widely used in wearable devices and foldable electronics. However, their flexibility comes at the cost of reduced bending strength, meaning they are less durable under heavy loads.

For designs that require a mix of rigidity and flexibility, rigid-flex PCBs combine thicker rigid sections (e.g., 1.6mm) with thinner flexible areas (e.g., 0.2mm). This hybrid approach is common in medical equipment and aerospace systems, where space constraints and durability are both critical.

Standard PCB Thickness Uses Across Industries

Different industries have unique requirements that dictate the choice of PCB thickness. Here’s a breakdown of standard PCB thickness uses in various applications:

Consumer Electronics

In consumer electronics like smartphones and laptops, thinner PCBs (0.6mm to 1.0mm) are preferred to save space and reduce weight. These boards often use 2-4 layers to accommodate compact circuitry while maintaining adequate performance.

Automotive Systems

Automotive electronics, such as engine control units and infotainment systems, typically use 1.6mm to 2.0mm PCBs. These thicknesses provide the necessary bending strength to endure vibrations and temperature fluctuations while supporting 4-8 layers for complex wiring.

Industrial Equipment

Heavy industrial equipment often relies on thicker PCBs (2.4mm to 3.2mm) to handle high power and resist harsh conditions. These boards can support 12 or more layers, making them suitable for intricate control systems in manufacturing plants.

Medical Devices

Medical devices, especially wearable or implantable ones, frequently use ultra-thin PCBs (0.2mm to 0.4mm) for their flexibility and compact size. Rigid-flex designs are also common in diagnostic equipment, where both durability and adaptability are needed.

Aerospace and Military

In aerospace and military applications, reliability is paramount. Thicker PCBs (2.0mm to 3.2mm) are used for their superior bending strength and ability to handle extreme conditions. High layer counts ensure these boards can support complex systems like radar and communication hardware.

How to Choose the Right PCB Thickness for Your Project

Selecting the appropriate PCB thickness involves evaluating several factors to ensure optimal performance and manufacturability. Here are some practical tips to guide your decision:

- Consider the Application: Determine the environment and stress levels your PCB will face. For high-vibration settings, opt for thicker boards (1.6mm or above). For compact or flexible designs, choose thinner options (0.2mm to 0.8mm).

- Evaluate Electrical Needs: High-frequency or high-power applications may require specific thicknesses to maintain impedance or manage heat. For instance, a 1.0mm board might be ideal for RF signals with a controlled impedance of 50 ohms.

- Assess Layer Count: More layers often mean a thicker board. A 12-layer design might necessitate a 2.4mm thickness to accommodate all connections without compromising structural integrity.

- Balance Cost and Performance: Thicker boards and specialized materials can increase costs. Choose a thickness that meets your needs without exceeding your budget.

- Consult Manufacturing Capabilities: Ensure your chosen thickness aligns with standard manufacturing processes to avoid delays or additional costs.

Conclusion: Making Informed Decisions on PCB Thickness

Understanding the range of standard PCB thicknesses and their applications is essential for designing reliable and efficient circuit boards. From ultra-thin 0.2mm flexible PCBs to heavy-duty 3.2mm boards, each thickness offers unique advantages tailored to specific needs. By considering factors like PCB material properties, bending strength, flexibility, and industry requirements, you can select the ideal thickness for your project.

Whether you’re working on a compact wearable device or a robust industrial system, the right PCB thickness ensures optimal performance and durability. Use the PCB thickness chart provided in this guide as a starting point, and dive deeper into material properties and mechanical considerations to refine your design. With this knowledge, you’re well-equipped to create PCBs that meet the highest standards of quality and functionality.

ALLPCB

ALLPCB