Grounding was first applied in high-power systems, such as power grids and electrical equipment, to ensure equipment and personnel safety by connecting a ground wire directly to the earth. Because the earth has a very large capacitance, its potential is generally considered to be zero. This technique was later extended to low-power systems. In power electronics, a ground wire is connected directly to the earth or to a conductor that serves as a reference potential. Ideally, no voltage drop should occur when current flows through this reference. However, improper grounding can introduce electromagnetic interference (EMI), such as common-ground impedance and ground loop interference, causing equipment to malfunction. Therefore, grounding is a critical component of electromagnetic compatibility (EMC) in power electronics and warrants a detailed discussion.

2. Types and Purposes of Grounding

In power electronics, grounding generally serves the following purposes:

2.1 Safety Ground

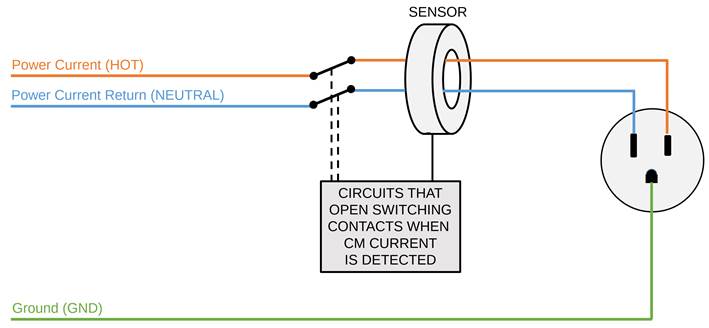

A safety ground connects the equipment chassis to the earth. This serves two functions: first, it prevents the accumulation of static charge on the chassis, which could lead to electrostatic discharge (ESD) that endangers equipment and personnel. Second, if insulation fails and the chassis becomes energized, it facilitates the activation of the power supply's protection circuit to cut off power, ensuring the safety of operators.

2.2 Lightning Protection Ground

When electronic equipment is struck by lightning, whether directly or through induction, it can suffer severe damage. Lightning rods are installed and grounded to protect equipment and personnel during a lightning strike.

Both safety and lightning protection grounds are primarily for safety and must be connected directly to the earth.

2.3 Working Ground

A working ground provides a reference potential for the normal operation of a circuit. This reference can be a specific point, section, or area within the circuit system. If this reference is not connected to the earth, it is considered a relative zero potential. This relative potential can fluctuate with external electromagnetic fields, leading to system instability. When connected to the earth, the reference potential is tied to the earth's zero potential and remains stable. However, incorrect implementation of a working ground can introduce interference, such as common-ground and ground loop issues.

To prevent interference between different circuits and ensure they operate compatibly, working grounds are classified based on the circuit's nature. These include DC ground, AC ground, digital ground, analog ground, signal ground, power ground, and power supply ground. These different grounds should be implemented separately.

2.3.1 Signal Ground

A signal ground is the common reference potential for sensors and signal sources. As signals are often weak and susceptible to interference, the requirements for the signal ground are high.

2.3.2 Analog Ground

An analog ground is the common reference potential for analog circuits. Analog circuits can handle both small-signal amplification and large-signal power amplification, as well as both low and high frequencies. This makes them both susceptible to receiving interference and capable of generating it. Therefore, careful consideration must be given to the placement and routing of analog grounds.

2.3.3 Digital Ground

A digital ground is the common reference potential for digital circuits. Because digital circuits operate with pulses, their sharp rising and falling edges, especially at high frequencies, can easily interfere with analog circuits. The placement and routing of digital grounds also require careful planning.

2.3.4 Power Supply Ground

A power supply ground is the common reference potential for the power supply's zero rail. A power supply often provides power to multiple units within a system, each with potentially different power requirements and parameters. It is crucial to ensure both the stability of the power supply and the reliable operation of all other units.

2.3.5 Power Ground

A power ground is the common reference potential for load circuits or power driver circuits. These circuits typically involve high currents and voltages, making the power ground path a significant source of interference. Power grounds must be separated from other low-power grounds to ensure the stable and reliable operation of the entire system.

2.4 Shielding Ground

Shielding and grounding must be used together to be effective.

For electrostatic shielding, if a complete metal shield encloses a positively charged conductor, an equal amount of negative charge is induced on the inner surface of the shield, and an equal amount of positive charge appears on the outer surface. This means an electric field still exists outside the shield. If the metal shield is grounded, the positive charge on the outer surface flows to the earth, eliminating the external electric field and containing the conductor's electric field within the shield.

For alternating electric field shielding, a conductive metal shield placed between an interference source and a sensitive circuit can reduce coupled interference voltage. As long as the metal shield is well-grounded, the coupled interference can be minimized.

Both of these grounding applications are primarily for EMC.

3. Grounding Methods

Working grounds are implemented using different methods depending on the operating frequency:

3.1 Single-Point Grounding

For low-frequency circuits (<1 MHz), single-point grounding is used. In this scheme, all ground connections in the circuit system are brought to a single reference point, often a dedicated ground bolt, to prevent common impedance coupling. For multiple circuits, single-point grounding can be implemented in series or parallel. Since series grounding creates common impedance coupling, parallel single-point grounding is preferred for low-frequency applications.

To prevent power-line frequency and other stray currents from interfering with the signal ground, the signal ground path should be insulated from the power ground and chassis ground. They should only be connected at the main safety ground bolt (except in floating ground systems).

The relationship between the length and cross-sectional area of a ground wire is:

S > 0.83L (1)

Where:

L = Length of the ground wire (m)

S = Cross-sectional area of the ground wire (mm2)

3.2 Multi-Point Grounding

For high-frequency circuits (>30 MHz), multi-point grounding is used. In this method, a ground plane replaces individual ground returns for each part of the circuit. The inductance of a ground lead is proportional to its frequency and length. At high frequencies, this increases common impedance and the resulting EMI. Therefore, ground paths must be as short as possible. With multi-point grounding, connections should be made to the nearest low-impedance ground plane.

3.3 Hybrid Grounding

For circuits operating between 1 MHz and 30 MHz, a hybrid approach is used. If the ground wire length is less than 1/20 of the operating signal's wavelength, use single-point grounding. Otherwise, use multi-point grounding.

3.4 Floating Ground

In a floating ground system, the circuit ground has no direct conductive connection to the earth. The advantage is that the circuit is isolated from the electrical properties of the earth ground. The disadvantages are susceptibility to parasitic capacitance, which can cause the ground potential to shift and increase induced noise in analog circuits, and the risk of static charge accumulation, which can lead to ESD damage or severe interference. The effectiveness of a floating ground depends on the insulation resistance, the amount of parasitic capacitance, and the signal frequency.

4. Grounding Resistance

4.1 Requirements for Grounding Resistance

Grounding resistance should be as low as possible. When current flows through the ground resistance, it creates a voltage drop. This voltage can cause common impedance interference, expose equipment to overvoltage events, and pose an electric shock hazard. Generally, a ground resistance of less than 4Ω is required. For mobile equipment, a resistance of less than 10Ω is acceptable.

4.2 Methods to Lower Grounding Resistance

Grounding resistance consists of the ground wire resistance, contact resistance, and earth resistance. Methods to lower it include:

- Reducing ground wire resistance: Use multi-strand wires with a large total cross-sectional area and short length.

- Reducing contact resistance: Ensure a tight, secure connection between the ground wire, ground bolt, and ground electrode. Increase the contact area and pressure between the ground electrode and the soil.

- Reducing earth resistance: Increase the surface area of the ground electrode and improve soil conductivity (e.g., by adding salt water to the soil).

4.3 Calculating Grounding Resistance

The resistance (R) of a vertical ground electrode is:

R = 0.366 (ρ / L) * log(4L / d) Ω (2)

Where:

ρ = Soil resistivity (Ω·m)

L = Depth of the ground electrode in the earth (m)

d = Diameter of the ground electrode (m)

For example, with loess soil (ρ ≈ 200 Ω·m), an electrode depth (L) of 2 m, and a diameter (d) of 0.05 m, the calculated ground resistance R is 80.67 Ω. If salt water is added to the soil to reduce ρ to 20 Ω·m, the resistance R drops to 8.067 Ω.

5. Shield Grounding

5.1 Shielding Can Grounding

Circuits susceptible to electromagnetic radiation, such as signal sources and amplifiers, should be enclosed in shielding cans. Due to parasitic capacitance between the signal circuit and the shield, the end of the signal ground path should be connected to the shield to negate its effects. The shield itself should be grounded to eliminate common-mode interference.

5.2 Cable Shield Grounding

Low-frequency circuits: The shield of a cable in a low-frequency circuit should be grounded at a single point, and this point should be the same as the circuit's ground reference point. For multi-layer shielded cables, each shield layer should be grounded at one point and insulated from the others.

High-frequency circuits: The shield of a cable in a high-frequency circuit should use multi-point grounding. If the cable length is greater than 0.15 times the signal wavelength, the shield should be grounded at intervals of 0.15 wavelengths. If this is not feasible, the shield must be grounded at both ends at a minimum.

5.3 System Shielding Ground

When an entire system must be protected from external EMI or must be prevented from emitting EMI, the whole system should be enclosed in a shield. This shield should be connected to the system ground.

6. Equipment Grounding

A single piece of equipment often contains multiple types of circuits, such as low-level signal circuits (high-frequency, digital, analog) and high-level power circuits (power supply, relays). The equipment enclosure provides mechanical strength and shielding against external EMI.

Key points for equipment grounding:

- The 50 Hz power supply neutral line should be connected at the safety ground bolt. For standalone equipment, this bolt is located on the metal chassis with a good electrical connection.

- To prevent the chassis from becoming energized and endangering personnel, the power neutral line must not be used as a substitute for the chassis ground line.

- To prevent interference from high-voltage, high-current circuits (power supply, relays) into low-level circuits (high-frequency, digital, analog), their grounds must be separated. The former is the power ground, and the latter is the signal ground. Signal grounds may be further divided into digital and analog grounds and must be insulated from the power and chassis grounds.

- The signal ground may have its own ground bolt, insulated from the equipment chassis. This signal ground bolt can be connected to the safety ground bolt in three ways, depending on performance: 1) no connection (floating ground); 2) direct connection (single-point ground); or 3) connection via a capacitor (e.g., 3 μF), creating a DC-floating, AC-grounded scheme. All other grounds converge at the safety ground bolt, typically located near the AC power inlet, which is then connected via a ground wire to an earth electrode.

7. System Grounding

Key points for system grounding:

- Follow the guidelines for equipment grounding.

- Connect equipment chassis to the rack/cabinet chassis using a dedicated ground wire.

- Connect the rack/cabinet chassis to the main system chassis using a dedicated ground wire.

- The system's main safety ground bolt is located on the system's metal enclosure with a good electrical connection.

- In a large system with many cabinets and devices, the number of digital, analog, power, and chassis ground wires can become excessive. In this case, consider using two parallel, semi-circular ground busbars that are insulated from the system chassis. One busbar serves as the signal ground bus, and the other serves as the shield and chassis ground bus. Local signal grounds connect to the nearest point on the signal bus. Local shield and chassis grounds connect to the nearest point on their bus. The shield/chassis busbar connects directly to the main safety ground bolt. The signal ground bus connects to the signal ground bolt (which then connects to the main ground point).

- When a system is powered by a three-phase supply, imbalanced loads can cause the neutral point potential to shift. To prevent this, the power neutral line is connected to the safety ground bolt, forcing the neutral point to zero potential and preventing related interference.

- The earth electrode should be a galvanized steel pipe with an outer diameter of at least 50 mm and a length of at least 2.0 m. When burying the electrode, drive it to a sufficient depth and pour salt water around it to lower resistance. A ground resistance of less than 4Ω is generally required (less than 10Ω for mobile systems).

8. Conclusion

Grounding techniques are essential for ensuring the safety of equipment and personnel and for the reliable operation of power electronics. Ground connections can be made directly to the earth or to a conductor serving as a reference potential. Improper grounding can introduce electromagnetic interference and cause equipment to malfunction. Therefore, grounding is a critical aspect of electromagnetic compatibility and requires thorough study and careful implementation.

ALLPCB

ALLPCB