Overview

As modern electronic devices become smaller and higher performing, crystal oscillators face pressure to shrink in size. Achieving a 1.2mm x 1.0mm miniature crystal oscillator represents an advanced point in current crystal oscillator technology. It breaks traditional size limits while maintaining high standards in performance and reliability. This article examines the implementation techniques for such miniature oscillators and their notable advantages.

Technical challenges in achieving 1.2mm x 1.0mm crystal oscillators

-

Material selection and cutting techniques

Manufacturing oscillators at this scale requires high-quality quartz crystal material and precision cutting techniques, such as laser cutting or high-precision mechanical cutting, to ensure wafer uniformity and surface finish. Because crystal thickness demands extremely tight tolerances, this step is critical to final device performance.

-

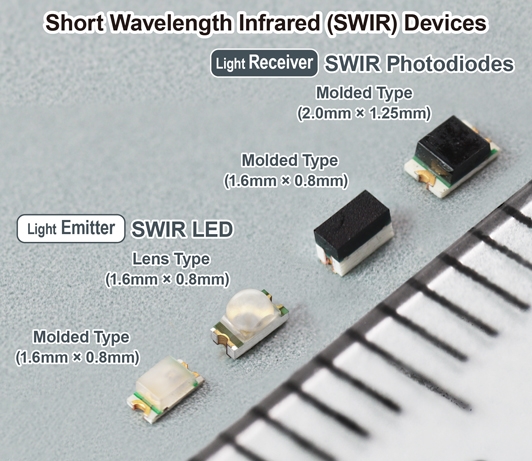

Miniature packaging technologies

Packaging is a core challenge for miniaturization. A 1.2mm x 1.0mm package typically uses low-temperature co-fired ceramic (LTCC) or other miniaturized packaging methods. These approaches allow integration of the crystal and oscillator circuitry in a very small footprint while providing protection against environmental effects. Package hermeticity must be ensured to maintain long-term stability and reliability.

-

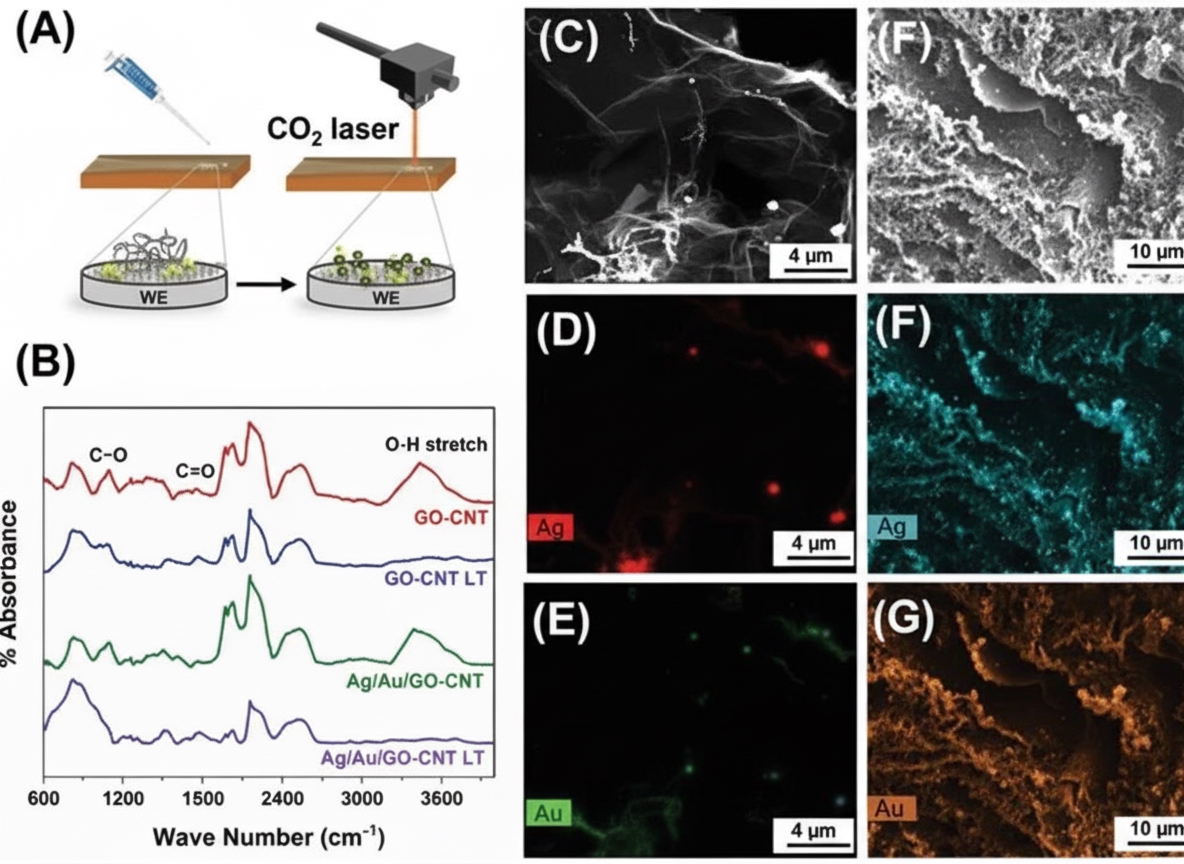

Electrode and soldering techniques

Designing and fabricating micro-electrodes and performing precise soldering on such small crystals is difficult. Processes like sputtering or electroplating are commonly used to form ultra-thin electrode layers on the crystal surface, followed by techniques such as eutectic soldering to connect to the PCB. These precision processes ensure reliable electrical connections and mechanical strength.

-

Frequency trimming and testing

Smaller size increases the precision required for frequency trimming, using methods such as laser trimming or ion implantation to achieve fine frequency adjustments. Each oscillator produced must undergo strict testing with automated test equipment to verify conformance to specifications.

-

Thermal management and reliability

Miniature oscillators are highly sensitive to temperature changes, so designs must mitigate thermal effects on oscillation frequency by optimizing materials and package structure. Such design measures ensure frequency stability and long-term reliability across temperature ranges.

Advantages of 1.2mm x 1.0mm crystal oscillators

-

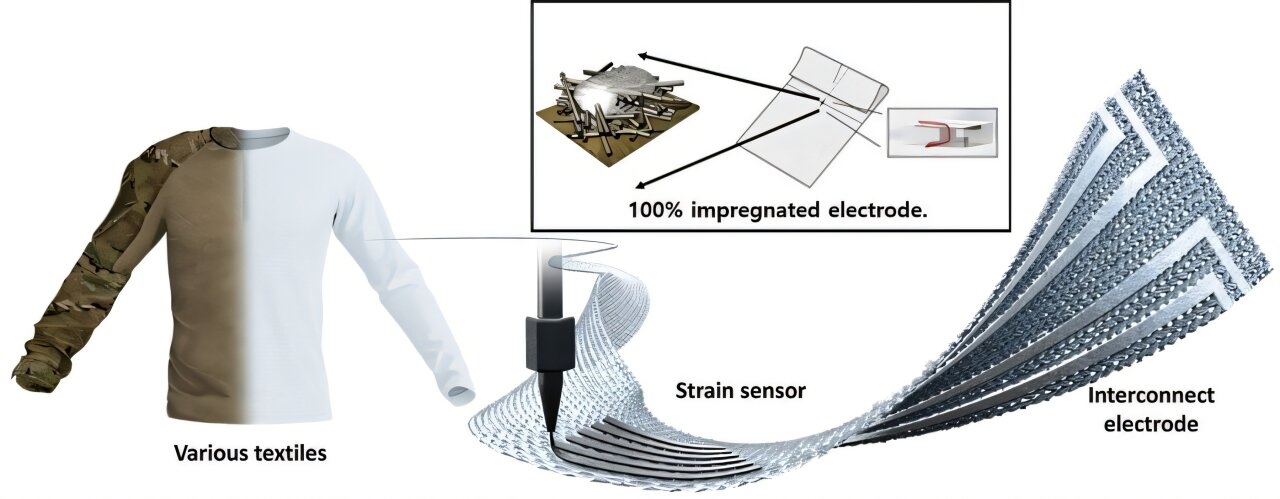

Compact size

These miniature oscillators save significant PCB space and are well suited to space-constrained applications such as wearables, ultra-thin smartphones, tablets, and portable medical devices. Their small footprint also facilitates integration into complex circuit designs, increasing overall system integration.

-

Lightweight

The small size yields very low weight, which benefits weight-sensitive devices such as drones, wireless earbuds, and fitness trackers by reducing overall device mass.

-

High performance

Despite their small size, these oscillators can provide high-precision, high-stability frequency outputs suitable for timing-critical applications such as GPS, wireless communications, and precision instruments. They also tend to have low power consumption, making them appropriate for battery-powered devices.

-

Better adaptability

The compact form factor gives designers greater flexibility when arranging PCB layouts, enabling optimized routing and component placement to improve overall system performance and reliability. These oscillators are widely used in micro sensors, implantable medical devices, and IoT devices to meet diverse application requirements.

-

Enhanced reliability

Miniature oscillators often exhibit good resistance to vibration and shock, making them suitable for portable and mobile applications. Advanced packaging techniques help ensure long-term stability in harsh environments.

-

Support for modern manufacturing

1.2mm x 1.0mm oscillators are highly compatible with modern automated assembly equipment, which can improve production efficiency and reduce manufacturing costs. As semiconductor and packaging technologies evolve, these oscillators can meet the needs of 5G, communications, AI, and IoT devices.

ALLPCB

ALLPCB