10m Semi-Anechoic Chamber

EMCT-10 is a semi-anechoic chamber designed for a 10 m test distance. The system typically consists of a main chamber, a control room, and an amplifier room (a conducted test room is optional). It is intended for radiated immunity testing at 10 m or 3 m and for radiated emission compliance testing.

Main performance

- Radiated immunity testing: compliant with IEC/EN 61000-4-3.

- Radiated emission testing: compliant with EN 50022, EN 50147-2, GJB 151A and GJB 152A.

- Quiet zone: cylindrical volume 4 m diameter by 2 m height (larger sizes available on request).

- Shielding effectiveness: meets EN 50147-1 or better.

- Normalized site attenuation (NSA): selectable compliance with CISPR 16-1-4 and ANSI C63.4 in the 30 MHz–1 GHz range at ±3.5 dB, ±3.0 dB, or ±2.5 dB.

- Field uniformity (FU): measured per IEC 61000-4-3, within 0–6 dB.

- Site voltage standing wave ratio (sVSWR): per CISPR 16-1-4, not greater than 6 dB in the 1 GHz–18 GHz range.

- Ambient background noise (ABN): at least 10 dB below CISPR22 limits.

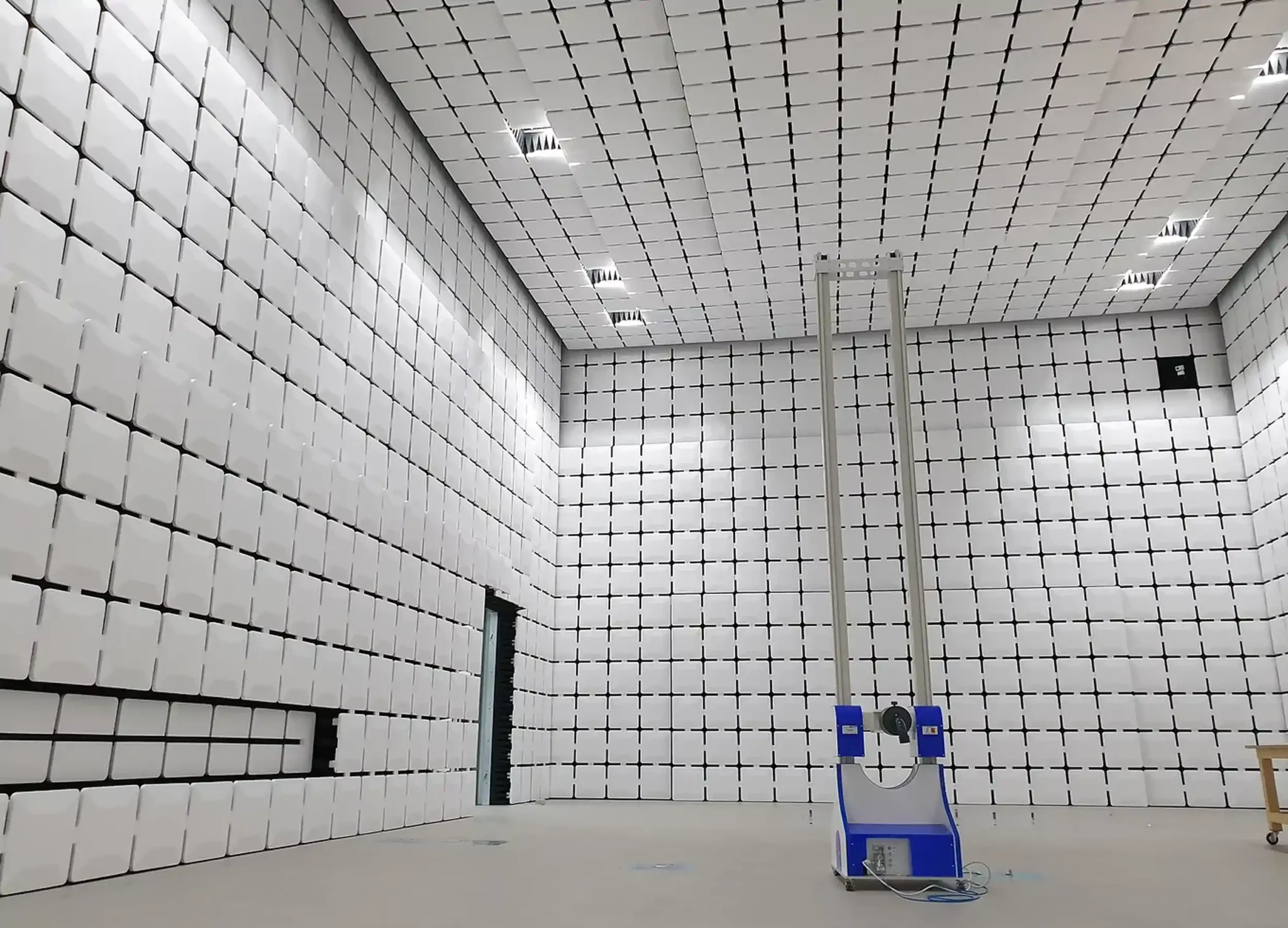

5m Semi-Anechoic Chamber

EMCT-5 is a semi-anechoic chamber designed for a 5 m test distance. The system normally includes a 5 m main chamber, an operations control room, and an amplifier room (conducted test room optional). It supports radiated immunity testing at 3 m and radiated emission testing at 5 m or 3 m.

The 5 m chamber addresses testing for larger electronic products. While retaining full 3 m capabilities, the quiet zone can be expanded to a 3 m diameter or larger. Typical applications include IT equipment, household appliances, medical devices, automotive components, small military electronics, industrial electronics, and communication devices.

Reference configuration

- Typical internal shielded dimensions: 12 m (length) × 8 m (width) × 6 m (height).

- Shielding structure: Smart Shield Twin Wall double-layer shielding. From inside out: high-performance composite conical absorber, ferrite absorber, corrosion-resistant multilayer panels, shield steel plate, and standard shield modules. Conductive shielding gaskets provide RF sealing and electrical contact between adjacent modules.

- Standard shield modules: 3 m × 1 m panels formed from 2 mm thick double-sided hot-dip galvanized steel, with galvanizing thickness ≥20 μm and uniform coverage. Modules are joined with M10 high-strength bolts (grade 8 or higher).

- Absorber installation: wall absorbers combine low-frequency ferrite tiles (nickel-zinc-manganese ferrite, 100 mm × 100 mm × 6.7 mm) and high-performance composite conical ESSORB-VHY-18-NRL absorbers (model selectable). Floor absorbers use ESSORB-VHY-12-NRL plus ferrite. A white reflective panel can cover the absorber to improve interior appearance and increase brightness.

- Shield doors: available in sizes such as 0.9 m × 2 m, 1.2 m × 2 m, 1.5 m × 2 m, and 2.0 m × 2.0 m. Custom sizes and types are available, including manual, electric, pneumatic, and automatic sliding doors.

- Waveguide window: standard 400 mm × 400 mm with flange, cutoff frequency up to 18 GHz. Alternate sizes such as 300 mm × 300 mm or 450 mm × 450 mm can be designed for cutoff frequencies up to 40 GHz.

- Built-in turntable: 3 m diameter, 2 t load capacity; custom sizes available.

- Raised floor: 2 t/m2 load capacity, typical height 30 cm, matched to the turntable load capacity.

- Filters: for power supplies 380 V, 220 V, 110 V, DC, and for network and communication signal filtering.

- Antenna mast: 4 m lift range, supports horizontal and vertical polarization and various antenna types.

- Video system: two digital color surveillance systems, one wall-mounted and one floor-mobile.

- Fire detection system: high-sensitivity air-sampling analysis system meeting applicable fire safety product regulations.

- Lighting: halogen lighting delivering 250 Lux at 1 m above the floor, adjustable.

Main performance

- Radiated immunity testing: compliant with IEC/EN 61000-4-3.

- Radiated emission testing: compliant with EN 50022, EN 50147-2, GJB 151A and GJB 152A.

- Quiet zone: cylindrical volume 3 m diameter by 2 m height.

- Shielding effectiveness: meets EN 50147-1 or better.

- Normalized site attenuation (NSA): selectable compliance with CISPR 16-1-4 and ANSI C63.4 in the 30 MHz–1 GHz range at ±3.5 dB, ±3.0 dB, or ±2.5 dB.

- Field uniformity (FU): measured per IEC 61000-4-3, within 0–6 dB.

- Site voltage standing wave ratio (sVSWR): per CISPR 16-1-4, not greater than 6 dB in the 1 GHz–18 GHz range.

- Ambient background noise (ABN): at least 10 dB below CISPR22 limits.

3m Semi-Anechoic Chamber

EMCT-3 is a semi-anechoic chamber designed for a 3 m test distance. The system normally consists of a 3 m main chamber, an operations control room, and an amplifier room (conducted test room optional). It supports radiated immunity and radiated emission compliance testing at 3 m. The complete chamber system can cover standards such as CISPR, EN, FCC, GB, and GJB, and can be upgraded to a full anechoic chamber.

The 3 m chamber is suitable for IT equipment, household appliances, medical devices, automotive components, small military electronics, industrial electronics, and communication devices. With special interfaces, it can also support testing of specific products such as water meters, gas meters, and electricity meters.

Main performance

- Radiated immunity testing: compliant with IEC/EN 61000-4-3.

- Radiated emission testing: compliant with EN 50022, EN 50147-2, GJB 151A and GJB 152A.

- Quiet zone: cylindrical volume 2 m diameter by 2 m height.

- Shielding effectiveness: meets EN 50147-1 or better.

- Normalized site attenuation (NSA): selectable compliance with CISPR 16-1-4 and ANSI C63.4 in the 30 MHz–1 GHz range at ±3.5 dB, ±3.0 dB, or ±2.5 dB.

- Field uniformity (FU): measured per IEC 61000-4-3, within 0–6 dB.

- Site voltage standing wave ratio (sVSWR): per CISPR 16-1-4, not greater than 6 dB in the 1 GHz–18 GHz range.

- Ambient background noise (ABN): at least 10 dB below CISPR22 limits.

Reference configuration

- Typical internal shielded dimensions: 9 m (length) × 6 m (width) × 6 m (height).

- Shielding structure: Smart Shield Twin Wall double-layer shielding. From inside out: high-performance composite conical absorber, ferrite absorber, corrosion-resistant multilayer panels, shield steel plate, and standard shield modules. Conductive shielding gaskets provide RF sealing and electrical contact between adjacent modules.

- Standard shield modules: 3 m × 1 m panels formed from 2 mm thick double-sided hot-dip galvanized steel, with galvanizing thickness ≥20 μm and uniform coverage. Modules are joined with M10 high-strength bolts (grade 8 or higher).

- Absorber installation: wall absorbers combine low-frequency ferrite tiles (nickel-zinc-manganese ferrite, 100 mm × 100 mm × 6.7 mm) and high-performance composite conical ESSORB-VHY-18-NRL absorbers (model selectable). Floor absorbers use ESSORB-VHY-12-NRL plus ferrite. A white reflective panel can cover the absorber to improve interior appearance and increase brightness.

- Shield doors: available in sizes such as 0.9 m × 2 m, 1.2 m × 2 m, 1.5 m × 2 m, and 2.0 m × 2.0 m. Custom sizes and types are available, including manual, electric, pneumatic, and automatic sliding doors.

- Waveguide window: standard 400 mm × 400 mm with flange, cutoff frequency up to 18 GHz. Alternate sizes such as 300 mm × 300 mm or 450 mm × 450 mm can be designed for cutoff frequencies up to 40 GHz.

- Built-in turntable: 2 m diameter, 1 t load capacity; custom sizes available.

- Raised floor: 1 t/m2 load capacity, typical height 20–30 cm, matched to the turntable load capacity.

- Filters: for power supplies 380 V, 220 V, 110 V, DC, and for network and communication signal filtering.

- Antenna mast: 4 m lift range, supports horizontal and vertical polarization and various antenna types.

- Video system: two digital color surveillance systems, one wall-mounted and one floor-mobile.

- Fire detection system: high-sensitivity air-sampling analysis system meeting applicable fire safety product regulations.

- Lighting: halogen lighting delivering 250 Lux at 1 m above the floor, adjustable.

ALLPCB

ALLPCB