In the world of high-power electronics, effective thermal management is critical to ensure performance, reliability, and longevity. When it comes to choosing the right printed circuit board (PCB) for heat dissipation, two popular options stand out: glass-reinforced PCBs and metal core PCBs. So, which one offers better PCB thermal conductivity and heat dissipation for high power PCB design? In short, metal core PCBs generally outperform glass-reinforced PCBs in thermal management due to their superior conductivity, making them ideal for demanding applications. However, glass-reinforced PCBs still have their place in specific scenarios where cost and electrical insulation are priorities. In this detailed comparison, we’ll dive deep into the strengths and weaknesses of each type, helping you make an informed decision for your next project.

Understanding Thermal Management in High-Power Applications

High-power applications, such as LED lighting, power supplies, automotive electronics, and industrial equipment, generate significant heat during operation. If this heat isn’t managed properly, it can lead to component failure, reduced efficiency, and shortened device lifespan. Effective heat dissipation PCB design is essential to transfer heat away from critical components and maintain optimal operating temperatures.

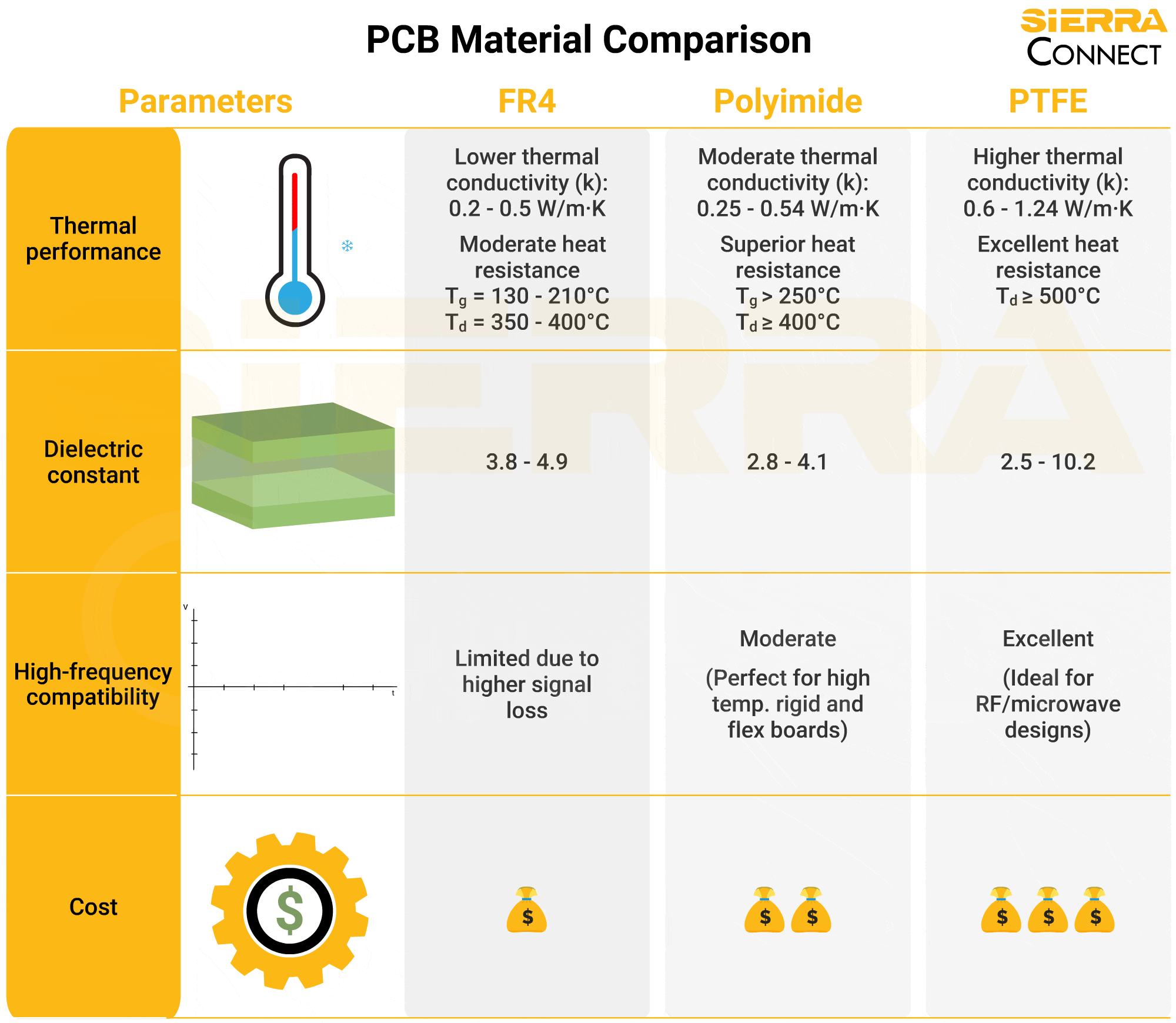

PCBs play a central role in thermal management. The material and structure of a PCB determine how well it can conduct and dissipate heat. Two common choices for managing heat in high-power designs are glass-reinforced PCBs (often made with materials like FR4) and metal core PCBs (often abbreviated as MCPCBs). Let’s explore the basics of each before diving into a head-to-head comparison.

What Are Glass-Reinforced PCBs?

Glass-reinforced PCBs are the most common type of circuit board used in electronics. They are typically made from a composite material, such as FR4, which consists of woven fiberglass cloth impregnated with an epoxy resin. This construction provides a good balance of electrical insulation, mechanical strength, and affordability.

In terms of glass PCB thermal performance, these boards have a relatively low thermal conductivity, usually around 0.3 to 0.5 W/m·K. This means they are not inherently good at transferring heat away from components. For high-power applications, additional thermal management techniques, such as heat sinks or thermal vias, are often required to compensate for this limitation.

Advantages of Glass-Reinforced PCBs

- Cost-Effective: These PCBs are widely available and inexpensive to manufacture, making them a go-to choice for many designs.

- Electrical Insulation: The fiberglass and epoxy materials provide excellent insulation, reducing the risk of short circuits.

- Versatility: They are suitable for a wide range of applications, from low-power consumer electronics to moderately high-power systems with additional cooling solutions.

Disadvantages of Glass-Reinforced PCBs

- Poor Thermal Conductivity: Their low ability to conduct heat makes them less ideal for high-power applications without additional cooling mechanisms.

- Limited Heat Dissipation: Without proper design adjustments, heat can build up, leading to potential component damage.

What Are Metal Core PCBs?

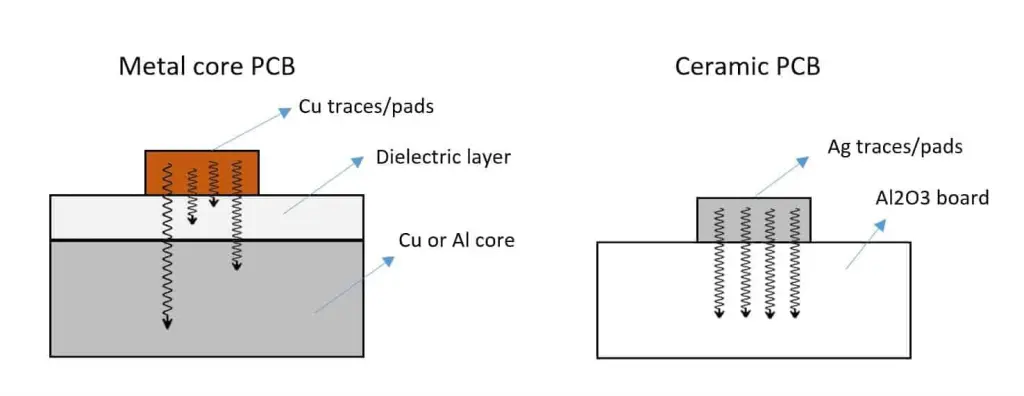

Metal core PCBs, or MCPCBs, are designed specifically for applications requiring superior heat dissipation. These boards feature a metal base layer, typically aluminum or copper, which acts as a heat spreader. Sandwiched between the metal base and the circuit layer is a thin dielectric layer that provides electrical insulation while allowing heat to pass through to the metal core.

With a thermal conductivity ranging from 1 to 4 W/m·K for aluminum-based MCPCBs (and even higher for copper-based ones), metal core PCB designs excel in transferring heat away from components. This makes them a top choice for high-power applications where thermal management is a primary concern.

Advantages of Metal Core PCBs

- High Thermal Conductivity: The metal base layer efficiently conducts heat, reducing hot spots on the board.

- Enhanced Heat Dissipation: Heat is spread across the metal core and can be further dissipated with heat sinks or other cooling methods.

- Durability: The robust construction of MCPCBs makes them resistant to thermal stress and mechanical damage, ideal for harsh environments.

Disadvantages of Metal Core PCBs

- Higher Cost: The materials and manufacturing processes for MCPCBs are more expensive than those for glass-reinforced PCBs.

- Weight: The metal base adds weight to the board, which may be a concern in portable or lightweight designs.

- Design Complexity: Working with MCPCBs often requires specialized design considerations and manufacturing techniques.

Head-to-Head Comparison: Thermal Performance and Beyond

Now that we’ve covered the basics, let’s compare glass-reinforced PCBs and metal core PCBs across key factors relevant to high power PCB design. This will help you understand which option is better suited for your thermal management needs.

1. PCB Thermal Conductivity

Thermal conductivity measures how well a material can transfer heat. For glass-reinforced PCBs, the thermal conductivity is typically in the range of 0.3 to 0.5 W/m·K, which is quite low. In contrast, metal core PCB designs using aluminum offer conductivity values of 1 to 4 W/m·K, while copper-based MCPCBs can reach up to 7 W/m·K or higher. This stark difference means that MCPCBs are far more effective at moving heat away from critical components, making them the clear winner for high-power applications.

2. Heat Dissipation Efficiency

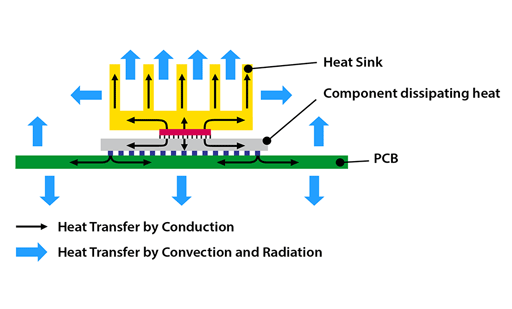

Effective heat dissipation PCB design is about more than just conductivity—it’s also about how well heat is spread and removed from the system. Glass-reinforced PCBs struggle in this area because their materials retain heat, often requiring external solutions like heat sinks or fans. Metal core PCBs, on the other hand, distribute heat evenly across the metal base, preventing localized hot spots and improving overall thermal performance. For applications like high-power LED lighting, where heat dissipation is critical, MCPCBs are often the preferred choice.

3. Suitability for High-Power Applications

In high power PCB design, components often operate at elevated temperatures, generating heat fluxes that can exceed 100 W/cm2 in extreme cases. Glass-reinforced PCBs can handle moderate power levels (up to around 10-20 W/cm2) with additional cooling, but they fall short in more demanding scenarios. Metal core PCBs are designed for these high-heat environments, supporting power densities well beyond 50 W/cm2 with proper design and cooling integration. This makes MCPCBs ideal for applications like automotive power electronics and industrial motor controls.

4. Cost and Accessibility

While performance is crucial, cost is always a factor in design decisions. Glass-reinforced PCBs are significantly cheaper, with costs often ranging from $0.10 to $0.50 per square inch for standard designs. Metal core PCBs, due to their specialized materials and manufacturing, can cost between $0.50 and $2.00 per square inch or more, depending on the metal used and board complexity. For budget-conscious projects with moderate thermal demands, glass-reinforced PCBs may be the better option.

5. Mechanical and Electrical Properties

Beyond thermal management, other properties matter in PCB selection. Glass-reinforced PCBs offer excellent electrical insulation, with dielectric strengths often exceeding 20 kV/mm, making them suitable for applications requiring high voltage isolation. Metal core PCBs, while still providing insulation through their dielectric layer, have a lower dielectric strength (typically around 1-3 kV/mm), which may limit their use in certain high-voltage scenarios. Mechanically, MCPCBs are more robust and resistant to thermal expansion stress, with a coefficient of thermal expansion (CTE) closer to that of mounted components (around 17-24 ppm/°C for aluminum) compared to glass-reinforced PCBs (around 12-15 ppm/°C for FR4).

Practical Applications: Where Each PCB Shines

Understanding where each type of PCB performs best can guide your design choices. Let’s look at some real-world scenarios.

Glass-Reinforced PCBs in Action

Glass-reinforced PCBs are often used in consumer electronics, such as smartphones, laptops, and home appliances, where power levels are moderate, and cost is a significant concern. For example, a standard laptop motherboard might dissipate around 5-10 watts of heat, which can be managed with FR4 material and small heat sinks or fans. In these cases, the glass PCB thermal performance is adequate with proper design.

Metal Core PCBs in Action

For high-power applications, metal core PCBs are the go-to solution. Take LED lighting systems, for instance. High-power LEDs can generate heat fluxes of 50 W/cm2 or more, requiring efficient heat dissipation to maintain performance and prevent degradation. An aluminum-based MCPCB can effectively spread this heat, extending the lifespan of the LEDs. Similarly, in automotive electronics, such as electric vehicle power converters, MCPCBs handle the intense heat generated by high-current components, ensuring reliability under demanding conditions.

Design Tips for Optimizing Thermal Management

Regardless of whether you choose a glass-reinforced or metal core PCB, optimizing your design for thermal performance is essential. Here are some practical tips to enhance heat dissipation PCB efficiency:

- Use Thermal Vias: Place thermal vias near heat-generating components to transfer heat to other layers or a heat sink. This is especially useful for glass-reinforced PCBs.

- Select Appropriate Materials: For glass-reinforced PCBs, consider higher-grade FR4 with better thermal properties if budget allows. For MCPCBs, choose aluminum for cost-effectiveness or copper for maximum conductivity.

- Integrate Heat Sinks: Attach heat sinks directly to the PCB or components to draw heat away. Metal core PCBs can often act as a heat sink themselves when designed properly.

- Optimize Component Placement: Spread out high-power components to avoid concentrated heat build-up, and place them near areas with better heat dissipation paths.

- Simulate Thermal Performance: Use thermal simulation software to predict heat distribution and identify potential hot spots before manufacturing.

Conclusion: Choosing the Right PCB for Your Needs

When it comes to thermal management in high power PCB design, the choice between glass-reinforced PCBs and metal core PCBs depends on your specific requirements. If cost and electrical insulation are top priorities, and your application operates at moderate power levels, glass-reinforced PCBs can work well with additional cooling solutions. However, for demanding environments where superior PCB thermal conductivity and heat dissipation are non-negotiable, metal core PCB designs are the better choice due to their ability to handle high heat fluxes effectively.

By understanding the strengths and limitations of each type, you can make an informed decision that balances performance, cost, and design complexity. Whether you’re working on LED lighting, automotive systems, or industrial electronics, prioritizing thermal management will ensure your designs operate reliably for years to come. For expert guidance and high-quality PCB solutions tailored to your thermal needs, trust a reliable manufacturing partner to bring your vision to life.

ALLPCB

ALLPCB