In the fast-paced world of electronics manufacturing, effective inventory management is the backbone of a successful PCB assembly process. Struggling with stockouts, overstock, or misplaced components can lead to costly delays and production hiccups. So, how can you master inventory control for PCB assembly? The secret lies in adopting proven techniques like precise component tracking, reducing stockouts, and implementing FIFO (First-In, First-Out) inventory systems. In this comprehensive guide, we’ll uncover actionable strategies for PCB inventory control techniques, component tracking in PCB assembly, reducing stockouts in electronics manufacturing, and FIFO PCB inventory practices to streamline your operations and boost efficiency.

Why Inventory Management Matters in PCB Assembly

Inventory management is more than just keeping track of parts; it’s about ensuring that your production line runs smoothly without interruptions. In electronics manufacturing, where material costs can account for up to 80% of a finished PCB’s expense, poor inventory practices can lead to significant financial losses. A single missing component, like a 0402 resistor or a specific microcontroller, can halt an entire production run, costing thousands in downtime. On the flip side, overstocking ties up capital and storage space, increasing the risk of obsolete inventory as technology evolves rapidly.

Effective inventory management directly impacts lead times, customer satisfaction, and profitability. By mastering PCB inventory control techniques, manufacturers can maintain a delicate balance—having just enough stock to meet demand without excess. Let’s dive into the core strategies that can transform your inventory processes.

Key Challenges in PCB Inventory Management

Before exploring solutions, it’s important to understand the common hurdles in managing inventory for PCB assembly. These challenges include:

- Component Variety: A single PCB can require hundreds of unique components, from tiny passives to complex ICs, each with different lead times and suppliers.

- Stockouts: Running out of critical parts mid-production can delay projects by days or weeks, especially if a component has a long reorder time.

- Overstocking: Holding too many parts, especially for older designs, risks obsolescence as newer technologies emerge.

- Traceability Issues: Without proper tracking, identifying the source or batch of a defective component becomes a nightmare, affecting quality control.

Addressing these challenges requires a strategic approach. Let’s explore proven techniques to optimize inventory for PCB assembly.

Top PCB Inventory Control Techniques

1. Implement a Robust Inventory Management System

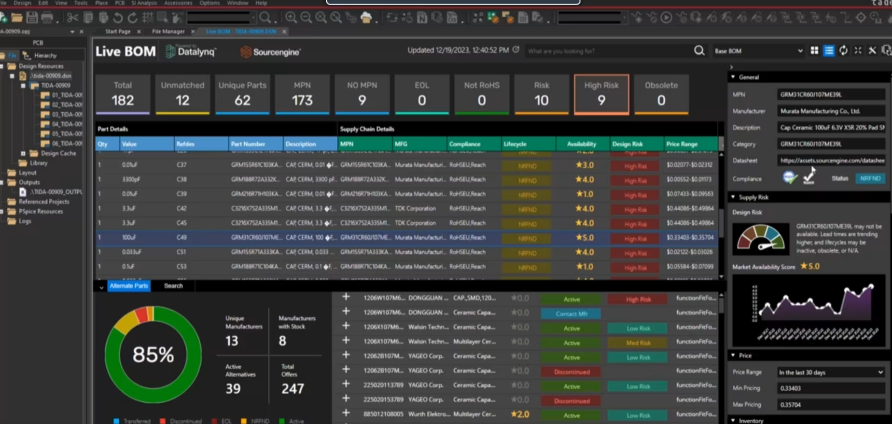

A digital inventory management system is the foundation of effective control. Manual tracking with spreadsheets often leads to errors, especially in high-volume environments. Modern software solutions can track stock levels in real-time, send alerts for low inventory, and generate reports on usage trends. For example, a system might notify you when your stock of a specific 1kΩ resistor drops below 500 units, allowing you to reorder before a shortage occurs.

Look for software that integrates with your ERP (Enterprise Resource Planning) system to sync inventory data with production schedules. This ensures that you only order what’s needed for upcoming builds, minimizing excess stock.

2. Adopt Just-In-Time (JIT) Inventory Practices

Just-In-Time inventory is a strategy that aims to reduce holding costs by ordering components only as they are needed for production. While JIT requires precise forecasting and reliable suppliers, it can significantly cut down on storage costs and reduce the risk of obsolete inventory. For instance, if a batch of 100 PCBs requires 500 capacitors of a specific value, you order only what’s necessary for that run, plus a small buffer.

However, JIT comes with risks, such as delays if a supplier fails to deliver on time. To mitigate this, maintain strong relationships with multiple suppliers and keep a small safety stock for critical components.

Mastering Component Tracking in PCB Assembly

Component tracking in PCB assembly is critical for quality control and efficiency. Traceability—the ability to track a component from procurement to final assembly—ensures that any issues, like defective parts, can be traced back to their source. Here’s how to enhance tracking:

1. Use Barcode or RFID Systems

Barcodes and RFID (Radio Frequency Identification) tags allow you to track components at every stage of the supply chain. Each reel, tray, or bag of components can be tagged with a unique identifier. Scanning these tags updates your inventory system instantly, reducing human error. For example, when a batch of 0603 SMD capacitors arrives, scanning the barcode logs the quantity, supplier, and batch number into your system.

RFID takes this a step further by enabling contactless scanning, which is ideal for high-volume operations where speed is essential.

2. Maintain Detailed Records for Traceability

Traceability is vital for compliance with industry standards like ISO 9001 and for troubleshooting defects. Record details such as supplier information, batch numbers, and date of receipt for every component. If a customer reports a failure in a PCB, you can trace the faulty capacitor or IC back to its batch and supplier, identifying whether the issue stems from a specific lot or manufacturing error.

Reducing Stockouts in Electronics Manufacturing

Stockouts are a major pain point in electronics manufacturing, leading to production delays and unhappy customers. Here are actionable strategies for reducing stockouts in electronics manufacturing:

1. Accurate Demand Forecasting

Predicting component needs based on historical data and upcoming orders is key to avoiding shortages. Analyze past production runs to identify patterns. For instance, if your data shows a consistent need for 10,000 units of a specific 10uF capacitor every quarter, you can plan reorders accordingly. Pair this with customer forecasts to account for seasonal spikes or new projects.

2. Set Reorder Points and Safety Stock Levels

Establish reorder points—thresholds at which you automatically reorder a component. For high-demand parts like standard resistors or LEDs, set a reorder point of 20% of your typical usage to give enough lead time for delivery. Additionally, maintain a safety stock—a small buffer of critical components—to cover unexpected delays or demand surges.

3. Build Strong Supplier Relationships

Reliable suppliers are your first line of defense against stockouts. Work with trusted vendors who can provide fast turnaround times and prioritize your orders during shortages. Diversify your supplier base to avoid dependency on a single source, especially for critical components like microcontrollers with long lead times (sometimes 12-16 weeks).

The Power of FIFO PCB Inventory Management

FIFO PCB inventory—First-In, First-Out—is a method that ensures older stock is used before newer stock. This is particularly important in electronics, where components can degrade over time or become obsolete due to design changes. Here’s how to implement FIFO effectively:

1. Organize Storage for FIFO Compliance

Arrange your inventory so that older components are always at the front of shelves or bins, making them the first to be picked for assembly. Label bins with receipt dates to avoid confusion. For example, if you receive a shipment of 1N4148 diodes on January 1st and another on February 1st, ensure the January batch is used first by placing it in an accessible spot.

2. Prevent Component Degradation

Some components, like electrolytic capacitors, have a limited shelf life and can degrade if stored too long. Using FIFO ensures that these parts are used before they expire, reducing waste. Check manufacturer datasheets for shelf-life guidelines—many capacitors, for instance, should be used within 2-3 years of manufacture.

3. Automate FIFO with Inventory Software

Modern inventory systems can flag older stock for priority use, ensuring FIFO compliance without manual oversight. When a new batch of components is logged, the system can automatically prioritize older batches for upcoming production runs.

Additional Tips for Streamlining Inventory Management

Beyond the core strategies, consider these additional practices to enhance your inventory processes:

- Conduct Regular Audits: Perform quarterly physical counts to verify that your digital records match actual stock. Discrepancies can signal theft, loss, or data entry errors.

- Standardize Component Usage: Reduce variety by standardizing components across designs where possible. For example, using a single 1kΩ resistor type across multiple projects simplifies inventory tracking.

- Train Your Team: Ensure staff are well-versed in inventory protocols, from scanning barcodes to following FIFO rules, to minimize errors.

Conclusion: Transform Your PCB Assembly with Smart Inventory Management

Mastering inventory management is a game-changer for electronics PCB assembly. By implementing PCB inventory control techniques like digital systems and JIT practices, enhancing component tracking in PCB assembly with barcodes and traceability, focusing on reducing stockouts in electronics manufacturing through forecasting and safety stock, and adopting FIFO PCB inventory methods, you can streamline operations and cut costs. These strategies not only prevent delays but also improve quality control and customer satisfaction.

Start small by assessing your current inventory setup and identifying gaps. Then, integrate one or two of these techniques, such as setting up a barcode system or establishing reorder points. Over time, build a comprehensive system that keeps your production line humming. With the right approach, inventory management becomes a competitive advantage in the fast-moving world of electronics manufacturing.

ALLPCB

ALLPCB