In modern manufacturing, production lines typically use PLC-based automation systems with fieldbus protocols for control and communication. Meanwhile, enterprise management systems rely on computer networks using TCP/IP. Bridging these systems to enable data communication, protocol conversion, analysis, storage, and forwarding is critical for efficient production management, such as rapid issuance of production instructions and real-time status updates. This need drives the development of data gateway technology.

Core Principles of Data Gateways

Data gateways connect disparate communication systems to enable data exchange. This involves physical connections between systems and software interfaces that adhere to each system's communication protocols. The gateway facilitates data transfer through receiving, extracting, and forwarding processes.

Implementation of Data Gateways

Data gateways require two key components: interfaces and data processing. Advances in computing provide diverse interface options and robust processing capabilities. A computer equipped with appropriate interfaces and data processing software can function as a data gateway.

Industrial control computers are a common example. Manufacturers design modular interfaces (cards) that integrate with general-purpose computer hosts. Users select interface modules and a host with sufficient processing power to build the gateway¡¯s hardware platform. Specialized software then enables advanced data analysis, storage, and forwarding.

Applications of Data Gateways

Data gateways primarily translate data between communication protocols. Their applications depend on how data is processed or utilized, categorizing gateways into general-purpose and specialized types.

General-Purpose Data Gateways

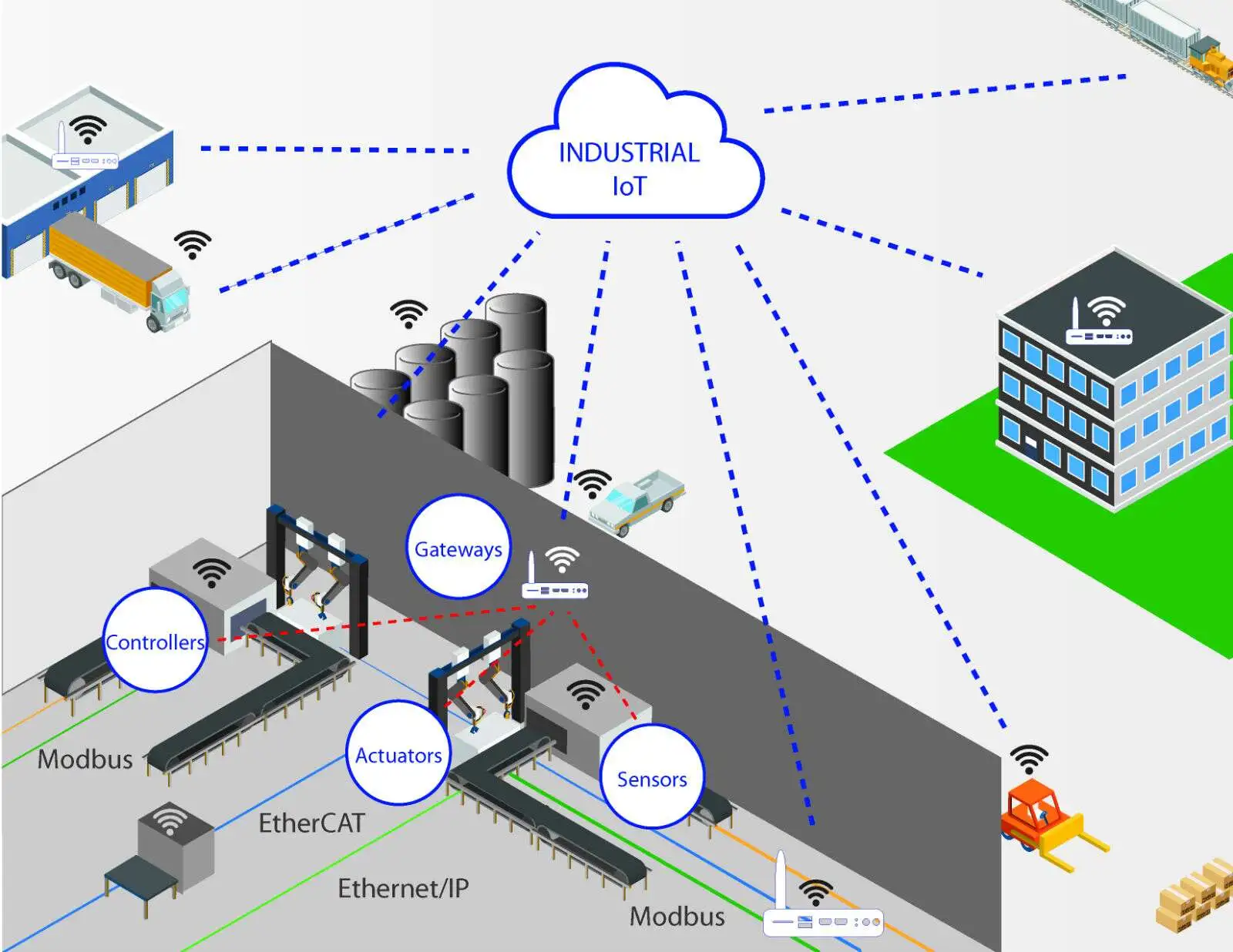

These gateways focus on data transmission with minimal processing, such as validity filtering, storage, or reorganization. A typical application is the operator interface system in control networks. This system connects to control systems via industrial Ethernet, fieldbus, or other methods, sending collected data to an operator¡¯s computer via TCP/IP for status display. It also relays operator commands to field PLCs, linking equipment and human-operated systems.

In this setup, the operator interface often integrates data conversion, effectively acting as the gateway. Additionally, modern enterprise systems like ERP, MES, and ASP require extensive data organization, storage, and forwarding to integrate with production control systems, making data gateways essential as information hubs.

In a comprehensive production control system, a data gateway connects production lines to command systems, serving as a data hub with the following capabilities:

- Real-time storage of production data and status, enabling long-term data retention for process analysis and quality traceability.

- Real-time reporting and publishing of production status, allowing managers to create efficient plans and marketers to track orders.

- Rapid issuance of production instructions from MES or ERP systems to the production line, enabling quick order responses and shorter delivery times.

- Enhanced system stability through networked operator stations that monitor the entire line and can substitute for each other if needed.

- Improved automation by supporting specialized computing devices for process and intelligent control, addressing limitations of standard PLCs in complex calculations or big data processing.

Specialized Data Gateways

Beyond basic storage and forwarding, specialized gateways integrate advanced functions, creating dedicated devices. Common types include:

- Information Publishing Gateways: These integrate web publishing, connecting to the internet via wired or wireless interfaces for remote access to real-time production data. Data isolation (via hardware or software) ensures production security.

- Process Control Gateways: Focused on data computation, these gateways enhance control for complex equipment, addressing PLC limitations in data processing, historical data access, or advanced algorithms.

- Information Storage Gateways: These prioritize local database creation for long-term data storage, offering multiple organization and query interfaces for process optimization and quality traceability.

Integration with Modern Technologies

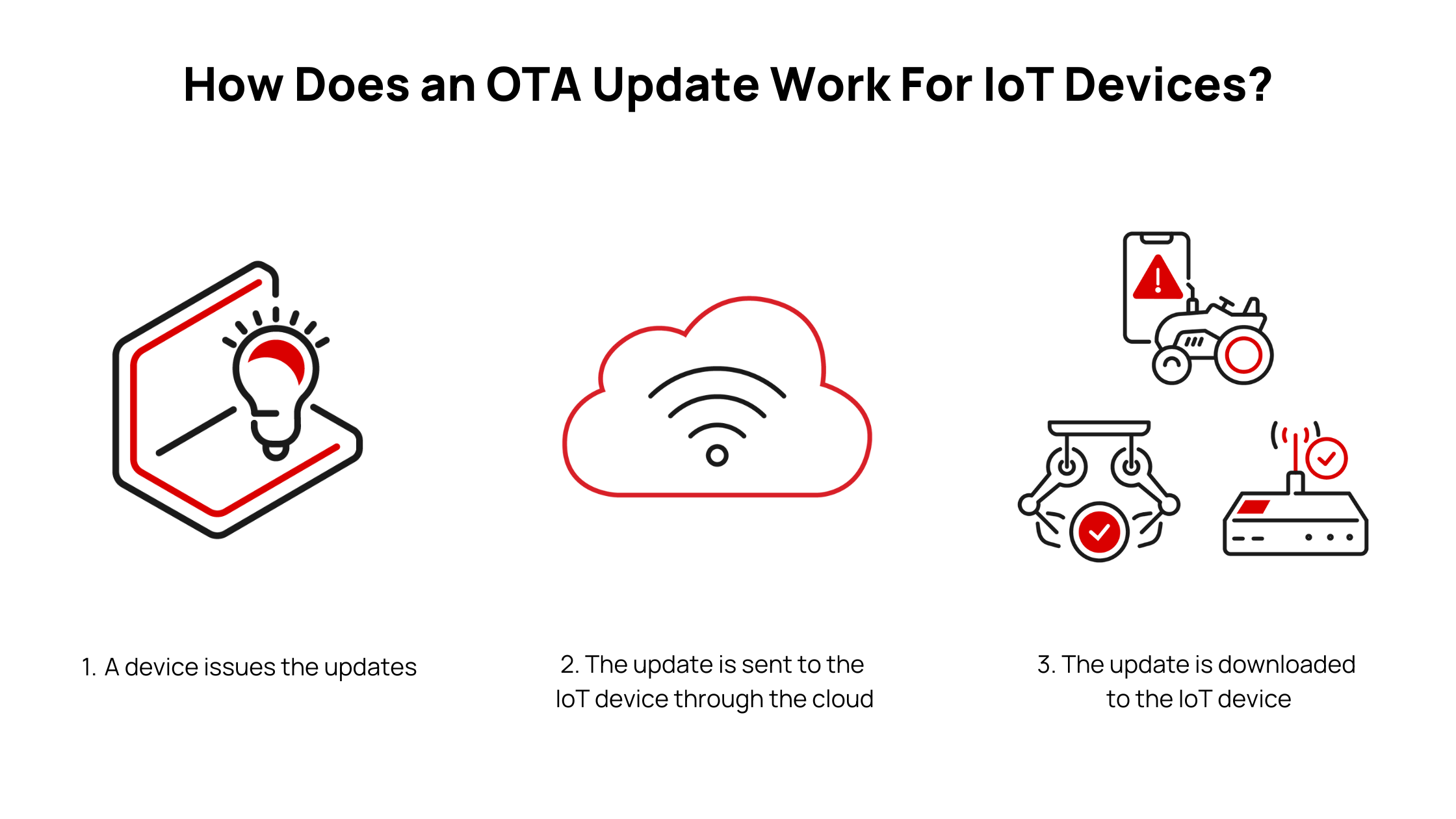

Emerging technologies like cloud computing and IoT, built on internet advancements, leverage data gateways to integrate with traditional industries.

Data Gateways and Cloud Computing

Gateways transmit production data to R&D, quality control, or professional analysis centers for in-depth processing. This enables optimized process parameters, improved product quality, and streamlined workflows with minimal hardware investment, balancing cost and efficiency.

Data Gateways and Mobile Connectivity

Gateways send real-time production data to decision-makers¡¯ mobile devices, enabling market-responsive strategies. Sales teams can track orders, update clients, and relay new demands to production, reducing costs and delivery times.

Data Gateways and IoT

Gateways integrate production line status with logistics data (raw materials, auxiliary materials, and finished goods) for holistic analysis. This optimizes scheduling, enhances resource use, enables just-in-time production, reduces inventory, and lowers logistics costs.

IoT Smart Gateways

IoT, combining smart sensors, RFID, and ubiquitous computing, is the third wave of global information technology. It aims to integrate sensing devices (e.g., RFID, infrared sensors) into the internet for seamless data exchange, intelligent identification, and monitoring.

Wireless sensor networks, often used in localized IoT applications, create isolated data islands due to incompatible protocols and limited long-range transmission. Diverse sensing technologies further complicate interoperability. IoT gateways bridge wireless sensor networks, traditional communication networks, and other network types, performing protocol conversion and enabling local and wide-area data connectivity. They also manage underlying sensor nodes, providing operators with node information and remote control capabilities.

Key Functions of IoT Gateways

IoT gateways perform three primary functions:

- Sensor Network Integration: Gateways access sensor networks, acquiring node attributes and statuses while enabling remote control, wakeup, and diagnostics for automated management.

- Heterogeneous Network Interoperability: Gateways support cross-domain communication with robust addressing to locate and query nodes accurately. As IoT scales, unique addressing schemes distinct from DNS are required.

- Standardized Communication and Data Formats: Gateways convert sensor network protocols to traditional network formats, encapsulating or unpacking data and commands to ensure compatibility.

In summary, IoT gateways collect sensor data, perform protocol conversion, and transmit data to public networks while providing management and control functions.

Sensor Network Integration

IoT gateways integrate diverse sensor networks, including cameras, card readers, tags, and acoustic, pressure, or temperature sensors. Access methods vary, with no universal standard. Common wired methods include CAN (used in automotive systems), RS232/485 (for legacy equipment), and Ethernet (for long-distance, high-volume data). Wireless methods include Zigbee (low-power, short-range), Bluetooth (real-time applications), IrDA (infrared point-to-point), and Wi-Fi (high-speed, broad coverage, but power-intensive).

Heterogeneous Network Interoperability

Different sensor networks use distinct protocols, causing data isolation. Gateways resolve this by enabling communication between physically connected but protocol-incompatible networks and ensuring sensor data can be accessed remotely. For example, Modbus, Profibus, or Interbus protocols in RS232/485 networks require TCP/IP encapsulation for internet access. Additionally, gateways must support IPv4-to-IPv6 transitions as IPv6 adoption grows.

Standardized Communication and Management

IoT gateways provide monitoring, control, and management of sensors and themselves, supporting flexible, user-friendly configuration via local or remote interfaces. They must accommodate diverse node types and use standardized communication to ensure system maintainability, managing both gateway and sensor network states.

As computing, sensing, and embedded technologies advance, smart gateways will play a growing role in intelligent systems, particularly in smart homes, with increasing maturity and adoption.

ALLPCB

ALLPCB