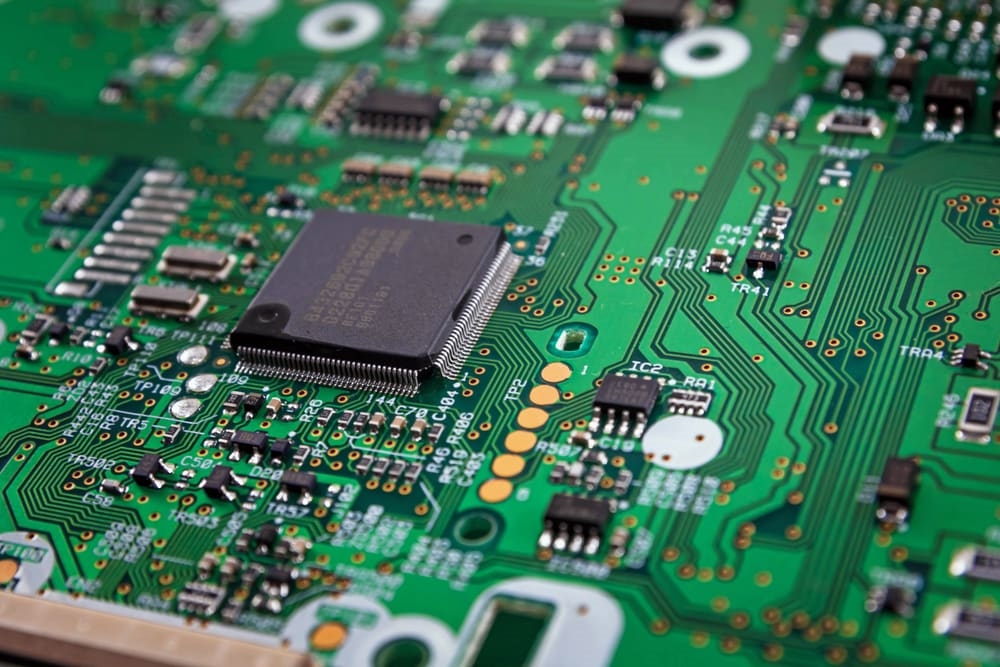

In the world of electronics, printed circuit boards (PCBs) are the backbone of almost every device. From smartphones to industrial machinery, PCBs connect and power the components that make technology work. But behind every high-quality PCB lies a complex supply chain of raw materials. How does raw material volume impact PCB manufacturing capacity, and what can be done to ensure stability? In short, the availability and volume of raw materials directly affect production speed, cost, and delivery timelines. Without a stable supply chain, even the best designs can face delays or quality issues.

This blog post dives deep into the relationship between raw materials and PCB manufacturing capacity. We'll explore the key materials needed, the challenges of maintaining consistent raw material volume, and strategies to build a resilient supply chain. Whether you're an engineer, a procurement specialist, or a business owner, this guide offers practical insights to help navigate the complexities of PCB production.

The Role of Raw Materials in PCB Manufacturing

PCBs are made from a combination of materials that work together to provide structure, conductivity, and insulation. The volume and quality of these raw materials play a critical role in determining manufacturing capacity. If there’s a shortage of even one key material, production can slow down or stop entirely. Let’s break down the main raw materials used in PCB manufacturing.

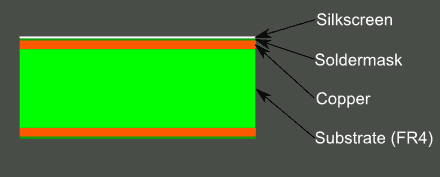

1. Substrates: The base layer of a PCB, often made from fiberglass or epoxy resin (commonly known as FR-4), provides structural support. Substrates account for a significant portion of raw material volume in PCB production. A steady supply of high-quality substrates is essential to meet production targets, especially for multilayer boards used in advanced electronics.

2. Copper Foil: Copper is the primary conductive material in PCBs, forming the traces and pads that carry electrical signals. Copper foil is typically measured in ounces per square foot, with common thicknesses ranging from 0.5 oz to 2 oz. A disruption in copper supply can directly limit the number of boards produced, as it’s a non-negotiable component.

3. Solder Mask and Silkscreen Inks: These materials provide insulation and labeling on the PCB. While they make up a smaller portion of raw material volume, shortages can still delay production by preventing the final protective layers from being applied.

4. Prepreg and Laminates: Used in multilayer PCBs, prepreg (pre-impregnated resin material) and laminates bond layers together. These materials must be available in sufficient quantities to meet the growing demand for complex, high-density boards in industries like telecommunications and automotive.

How Raw Material Volume Impacts PCB Manufacturing Capacity

The term "raw material volume" refers to the quantity of materials available for production at any given time. When raw material volume is low, manufacturers face several challenges that directly impact capacity. Here’s how:

1. Production Delays: If a manufacturer runs out of copper foil or substrates, production lines can come to a halt. For example, if a factory needs 10,000 square feet of copper foil per month to meet demand but only receives 7,000 square feet due to supply chain disruptions, output could drop by 30% or more.

2. Increased Costs: Low raw material volume often drives up prices due to scarcity. Manufacturers may need to pay a premium to secure limited stocks, which can increase the cost per board. This is especially true for specialized materials like high-frequency laminates used in 5G applications, where demand often outstrips supply.

3. Quality Issues: When raw material volume is inconsistent, manufacturers might turn to alternative suppliers or lower-grade materials to keep production going. This can lead to variations in board performance, such as reduced signal integrity or higher failure rates during testing. For instance, using a lower-quality substrate might result in impedance mismatches, affecting signal speeds in high-speed circuits (e.g., deviations from a standard 50-ohm impedance).

4. Limited Scalability: Without sufficient raw material volume, manufacturers can’t scale up production to meet sudden spikes in demand. This is a significant concern for industries like consumer electronics, where holiday seasons or product launches can create a surge in orders.

Challenges in Maintaining Raw Material Volume

Ensuring a consistent raw material volume is no easy task. The PCB supply chain is global, complex, and vulnerable to various disruptions. Below are some of the most common challenges manufacturers face:

1. Global Supply Chain Disruptions: Events like natural disasters, geopolitical tensions, or pandemics can interrupt the flow of raw materials. For example, a significant portion of copper foil is produced in specific regions, and any disruption there can create a ripple effect worldwide.

2. Fluctuating Demand: The electronics industry is highly dynamic, with demand for PCBs fluctuating based on market trends. A sudden increase in demand for electric vehicles, for instance, can strain the supply of high-performance laminates, leaving manufacturers scrambling to secure enough material.

3. Supplier Reliability: Not all suppliers can guarantee consistent raw material volume. Smaller suppliers may struggle to meet large orders, while larger ones might prioritize high-volume clients, leaving mid-sized manufacturers at a disadvantage.

4. Environmental Regulations: The production of raw materials like copper and resin is subject to strict environmental regulations. Compliance issues or policy changes can reduce output, impacting the available raw material volume for PCB manufacturing.

Strategies to Ensure a Stable Supply Chain for Raw Materials

Building a stable supply chain is critical for maintaining raw material volume and, by extension, PCB manufacturing capacity. Here are actionable strategies that can help:

1. Diversify Suppliers: Relying on a single supplier for critical materials like copper foil or substrates is risky. Partnering with multiple suppliers from different regions can reduce the impact of localized disruptions. For instance, sourcing copper from both Asian and European suppliers can provide a buffer if one region faces shortages.

2. Maintain Strategic Inventory: Stockpiling a reasonable amount of raw materials can help manufacturers weather short-term supply chain hiccups. For example, keeping a two-month supply of FR-4 substrates ensures production can continue even if a shipment is delayed.

3. Forecast Demand Accurately: Using historical data and market trends, manufacturers can predict raw material needs more accurately. If a company anticipates a 20% increase in PCB orders for the next quarter, they can order additional raw material volume in advance to avoid bottlenecks.

4. Build Strong Supplier Relationships: Long-term partnerships with reliable suppliers can ensure priority access to raw materials during shortages. Regular communication and transparent contracts help align expectations and secure consistent raw material volume.

5. Invest in Alternative Materials: Researching and testing alternative materials can provide flexibility. For example, if high-frequency laminates are in short supply, identifying a comparable material with similar dielectric constants (e.g., a Dk value of 3.5 for RF applications) can keep production on track.

The Future of Raw Material Supply in PCB Manufacturing

As technology advances, the demand for PCBs—and the raw materials needed to make them—continues to grow. Emerging trends like 5G, Internet of Things (IoT), and electric vehicles are driving the need for more complex, high-performance boards. This puts additional pressure on raw material volume and supply chain stability.

1. Sustainable Sourcing: With increasing focus on environmental impact, manufacturers are exploring sustainable raw materials. Recycled copper and eco-friendly resins are gaining traction, though scaling up production to meet global raw material volume needs remains a challenge.

2. Automation and Technology: Advanced inventory management systems and supply chain analytics can improve raw material tracking and forecasting. For instance, real-time data on supplier output can help manufacturers adjust orders dynamically, ensuring consistent raw material volume.

3. Regional Manufacturing Hubs: To reduce dependence on global supply chains, some companies are investing in regional production facilities. Localizing raw material sourcing and PCB manufacturing can minimize delays caused by international shipping or geopolitical issues.

How Manufacturers Can Support Your PCB Needs

Navigating the complexities of raw material volume and supply chain stability doesn’t have to fall entirely on your shoulders. Partnering with an experienced PCB manufacturer can make a significant difference. A reliable manufacturer will have established supplier networks, strategic inventory practices, and demand forecasting tools to ensure consistent production capacity.

Look for a partner that prioritizes transparency in their supply chain processes. They should be able to provide updates on raw material availability and offer solutions if disruptions occur. Additionally, a manufacturer with expertise in material selection can help optimize your PCB design for both performance and availability, ensuring that even niche materials are sourced efficiently.

Conclusion

The relationship between raw material volume and PCB manufacturing capacity is undeniable. A stable supply chain ensures that production runs smoothly, costs remain predictable, and delivery timelines are met. By understanding the key raw materials, recognizing the challenges of maintaining volume, and implementing strategies like supplier diversification and strategic inventory, manufacturers can build resilience against disruptions.

As the electronics industry continues to evolve, staying ahead of raw material supply challenges will be crucial. Whether you’re designing a simple single-layer board or a complex multilayer PCB for cutting-edge applications, a strong supply chain foundation is the key to success. With the right partnerships and proactive planning, you can ensure that your projects are never held back by raw material shortages.

ALLPCB

ALLPCB