Overview

This article examines battery technologies for the Internet of Things and describes power-related challenges faced by designers. It also summarizes Analog Devices solutions that address efficiency, size, weight, and temperature constraints common to IoT devices.

Why IoT Power Design Matters

As IoT devices become more common in industrial equipment, home automation, and medical applications, the pressure to optimize the power subsystem increases. Designers must reduce size, improve efficiency, lower current consumption, or shorten charging time, while maintaining a small form factor that does not create thermal issues or interfere with wireless communication.

What Is IoT?

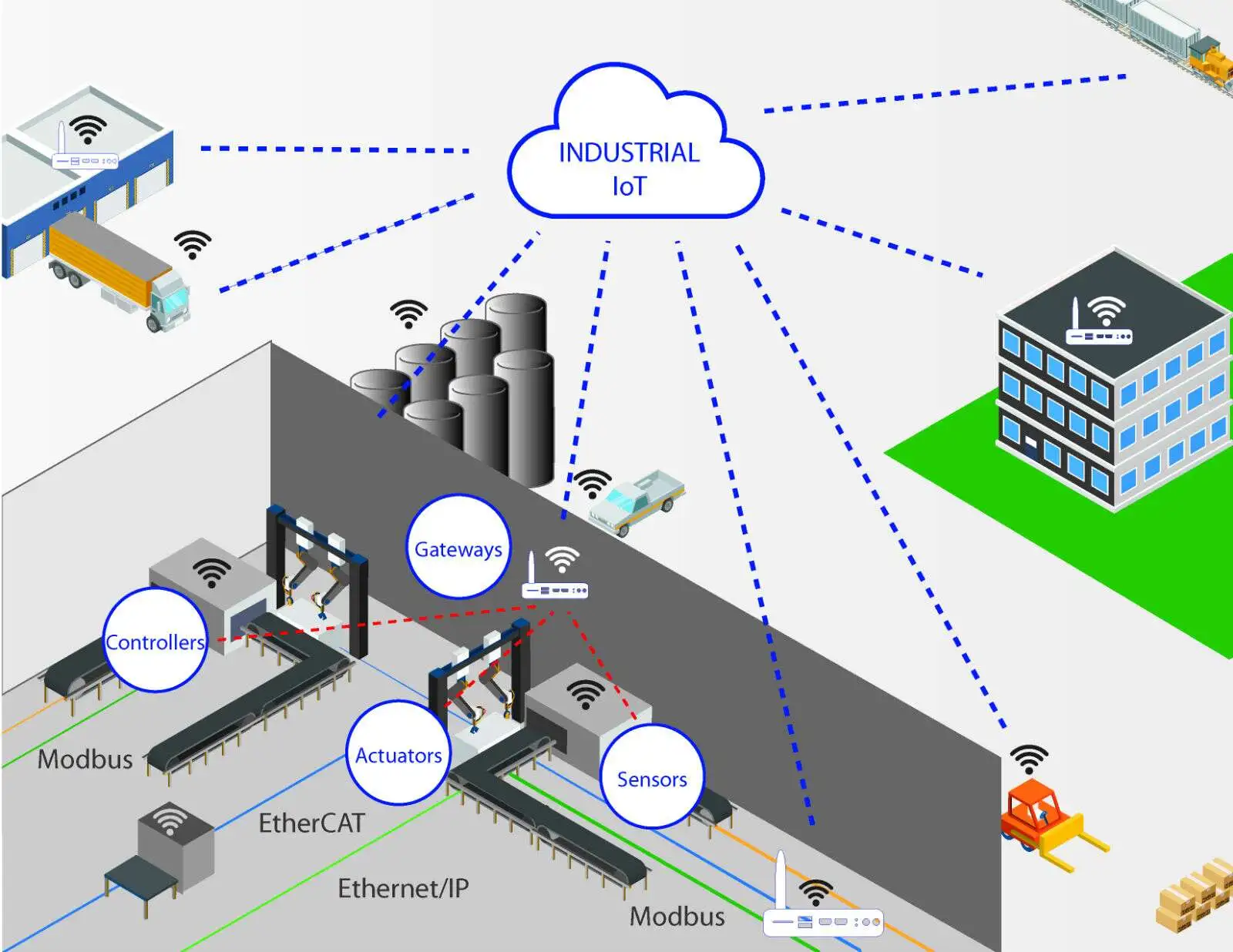

IoT typically refers to smart, networked electronic devices that may be battery powered and that send collected data to cloud infrastructure. These devices combine processors, communication ICs, sensors, and other embedded-system components to collect and transmit data to central points or other nodes on the network. Use cases range from simple room-temperature sensors to centralized monitoring systems and long-term machine health monitors that track expensive factory assets.

The goal of developing these devices is to address specific challenges: automating tasks that otherwise require human intervention (for example, home or building automation), improving availability and lifetime in industrial IoT, or enabling condition-based monitoring for infrastructure such as bridges to improve safety.

Example Applications

IoT use cases are extensive. Smart transmitters collect environmental data to make decisions about heating control, alarm triggering, or automated actions. Portable instruments such as gas meters and air-quality monitoring systems provide measurement data to control centers via the cloud. GPS tracking systems enable container and livestock tracking using smart tags. Other areas include wearable healthcare and infrastructure sensing.

Industrial IoT is a notable growth area and part of the Industry 4.0 transition. Applications aim to increase factory automation using automated guided vehicles, RFID tags, pressure sensors, and other smart sensors deployed across a facility to enable faster, more flexible, and leaner manufacturing.

From ADI's perspective, IoT focuses on five main areas:

- Smart health: vital-sign monitoring for clinical and consumer applications

- Smart factory: enabling faster, more flexible, and leaner factory responses to support industrial 4.0

- Smart building/smart city: using sensors for building security, parking occupancy detection, and thermal control

- Smart agriculture: automating agriculture and improving resource-use efficiency

- Smart infrastructure: condition-based monitoring of motion and structural health

Design Challenges for IoT Power

Most IoT nodes are installed post-construction or in hard-to-reach locations, making wired power impractical. These nodes therefore rely on batteries and/or energy harvesting. Running new power lines can be expensive and time consuming, so batteries or energy harvesting often remain the viable options.

Battery dependence imposes strict power budgets to ensure long battery life, which affects total cost of ownership. Battery replacement adds cost beyond the battery itself, including potential labor and disposal costs. It is also easy to overdesign a battery to meet long lifetime targets, such as 10+ years. Oversizing increases cost and size, so minimizing energy use and optimizing the power budget is important to allow the smallest battery that still meets design requirements.

Primary Power Types in IoT

For the purpose of power discussions, IoT applications can be grouped into three power scenarios:

- Devices powered by non-rechargeable primary batteries

- Devices using rechargeable batteries

- Devices using energy harvesting

These sources can be used alone or in combination, depending on the application.

Primary Battery Applications

Non-rechargeable primary batteries suit applications that are powered only intermittently, where the device spends most time in deep sleep and is only occasionally active. Advantages include high energy density, simpler design because no battery charging or management circuitry is required, and lower initial cost. Primary cells are ideal for low-cost, ultra-low-power applications, but they are less suitable where average power consumption is higher due to their finite energy.

In large installations with many nodes, replacing a single depleted battery often leads to replacing all batteries to save technician time, which is wasteful. Primary cells typically provide only about 2% of the energy that went into manufacturing them, so roughly 98% of that energy is unused, making them an inefficient energy source from a lifecycle perspective.

Primary cells nevertheless have a place in IoT because their low initial cost and simplicity make them suitable for many low-power applications. From a design standpoint, the key challenge is maximizing the useful energy drawn from the battery. Developing a power budget to achieve long lifetimes, often around 10 years, is critical.

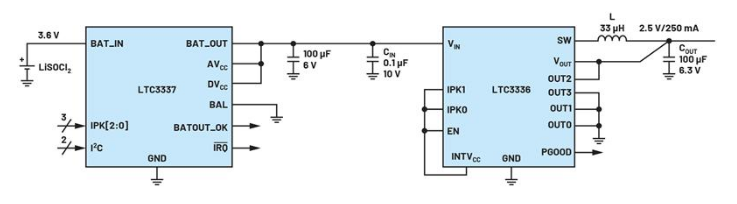

For primary battery applications, two low-power ADI parts warrant consideration: the LTC3337 nanoamp-level primary battery health monitor and coulomb counter, and the LTC3336 nanoamp-level buck regulator. The LTC3336 is a low-power DC-DC converter with input up to 15 V and programmable peak output current. It supports input voltages down to 2.5 V, making it suitable for battery-powered devices. Its no-load quiescent current is very low, about 65 nA. Output voltage is programmed by connections to the OUT0 through OUT3 pins.

The LTC3337 is a nanoamp-level primary battery health monitor and coulomb counter. It is straightforward to integrate: connect the IPK pin to the desired peak current range (5 mA to 100 mA) and perform calculations based on the selected battery to set recommended output limits per the datasheet. Together, these devices can accurately monitor primary battery energy and efficiently convert it to usable system voltage.

Rechargeable Battery Applications

Rechargeable batteries are suitable where battery replacement frequency is unacceptable or where higher average power is required. Rechargeable implementations have higher upfront costs due to the battery and charger circuitry, but for higher-power applications the cost is often justified because the battery can be recharged rather than replaced.

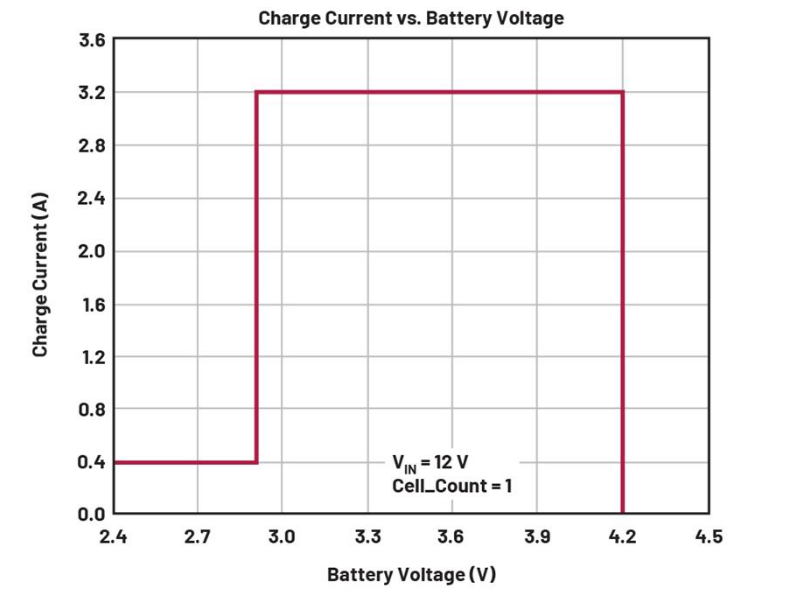

Rechargeable chemistries differ in charging modes and profiles. For example, a lithium-ion charging curve shows battery voltage on the horizontal axis and charging current on the vertical axis. When the battery is deeply discharged, the charger should enter a precharge mode to safely raise the voltage before entering constant-current charging. In constant-current mode, the charger supplies the set current until the battery reaches the float (constant-voltage) threshold. Charge current and voltage are defined by the battery type: charge current is limited by the C-rate and desired charging time, and float voltage is set for battery safety. Reducing float voltage slightly can extend battery life.

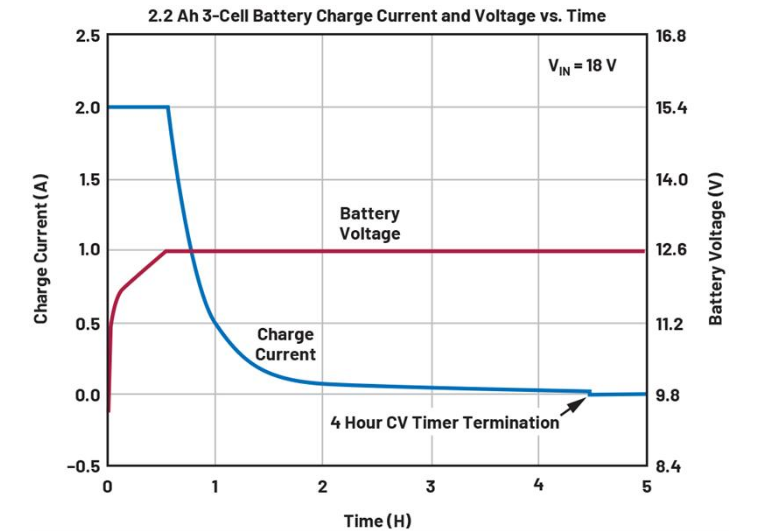

When the float voltage is reached, charge current falls toward zero and the voltage is maintained per the termination algorithm. The following chart illustrates a three-cell application charged with a 2 A constant-current stage until the battery reaches 12.6 V, then held at the 12.6 V threshold for a termination window (for example, four hours). That termination time is often programmable in charger ICs.

For more on battery charging and charger ICs, see related technical articles on battery charger ICs for different chemistries.

Energy Harvesting Applications

Energy harvesting is another option for IoT nodes. Harvesting can be attractive for low-power applications or installations that must operate without routine maintenance. Harvestable sources include solar, piezoelectric or vibration energy, thermoelectric, and even RF energy. Harvesting does not require outdoor placement; indoor light, body heat in wearables, or machinery heat can suffice.

Drawbacks include higher initial cost for harvesting elements such as solar panels, piezo transducers, or thermoelectric modules, plus the supporting energy conversion ICs and components. The physical size of a harvesting solution is often larger than a button cell or primary battery. Efficiency can be difficult to manage because many harvesters produce AC or low-voltage outputs requiring rectification, and diodes used for rectification introduce energy loss. This loss is reduced when input voltages are higher, but that is not always achievable.

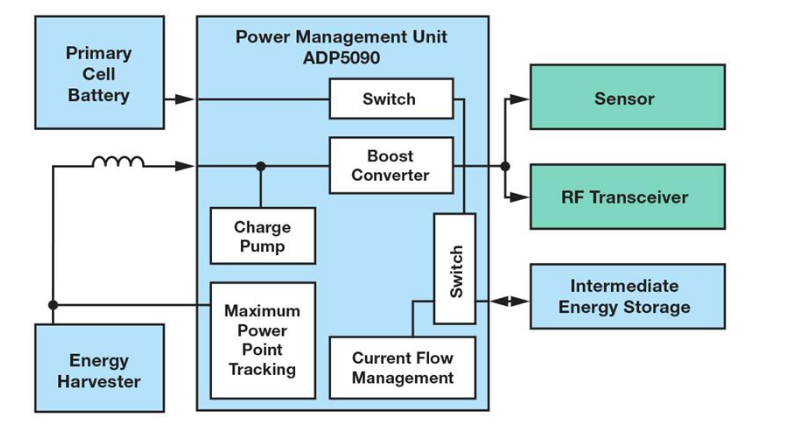

Common ADI harvesting products include the ADP509x series and the LTC3108. The LTC3108 supports a wide range of input sources, multiple power paths, and programmable charge-management options for flexible designs. ADP509x can be powered by various harvesters and can extract energy to charge batteries or supply the system. Suitable sources span solar (indoor and outdoor), thermoelectrics, piezo, and vibration, among others.

Energy Management

Any discussion of power-constrained applications should include energy management. Before evaluating power management ICs, develop a power-budget calculation for the application. This helps designers identify the key components that consume energy and determine how much energy each requires. Those results will guide decisions on battery selection, rechargeable designs, energy harvesting, or hybrids.

The frequency at which an IoT device collects signals and transmits data back to a central system or the cloud significantly affects overall power consumption. Common techniques include duty cycling the power and increasing the interval between wake-ups to collect or transmit data.

Using standby or low-power modes on electronic components, when available, is also an effective tool to reduce energy use.

Conclusion

Early consideration of power management is important for all electronic designs, and it is especially critical for power-constrained IoT applications. Creating a power budget early in the design process helps designers choose effective strategies and appropriate components to meet application requirements while maintaining small solution size and high energy efficiency.

ALLPCB

ALLPCB