If you're wondering whether backdrilling is worth the cost for your PCB project, the answer depends on your specific needs. For high-speed designs where signal integrity is critical, backdrilling can be a valuable investment, improving performance by reducing signal distortion. However, for simpler designs, the added cost may not justify the benefits. In this detailed guide, we'll explore the economics of backdrilling, including the cost of backdrilling PCB, its price impact, and a thorough cost-benefit analysis to help you decide if the ROI of backdrilling makes sense for your project.

What Is Backdrilling and Why Does It Matter in PCB Design?

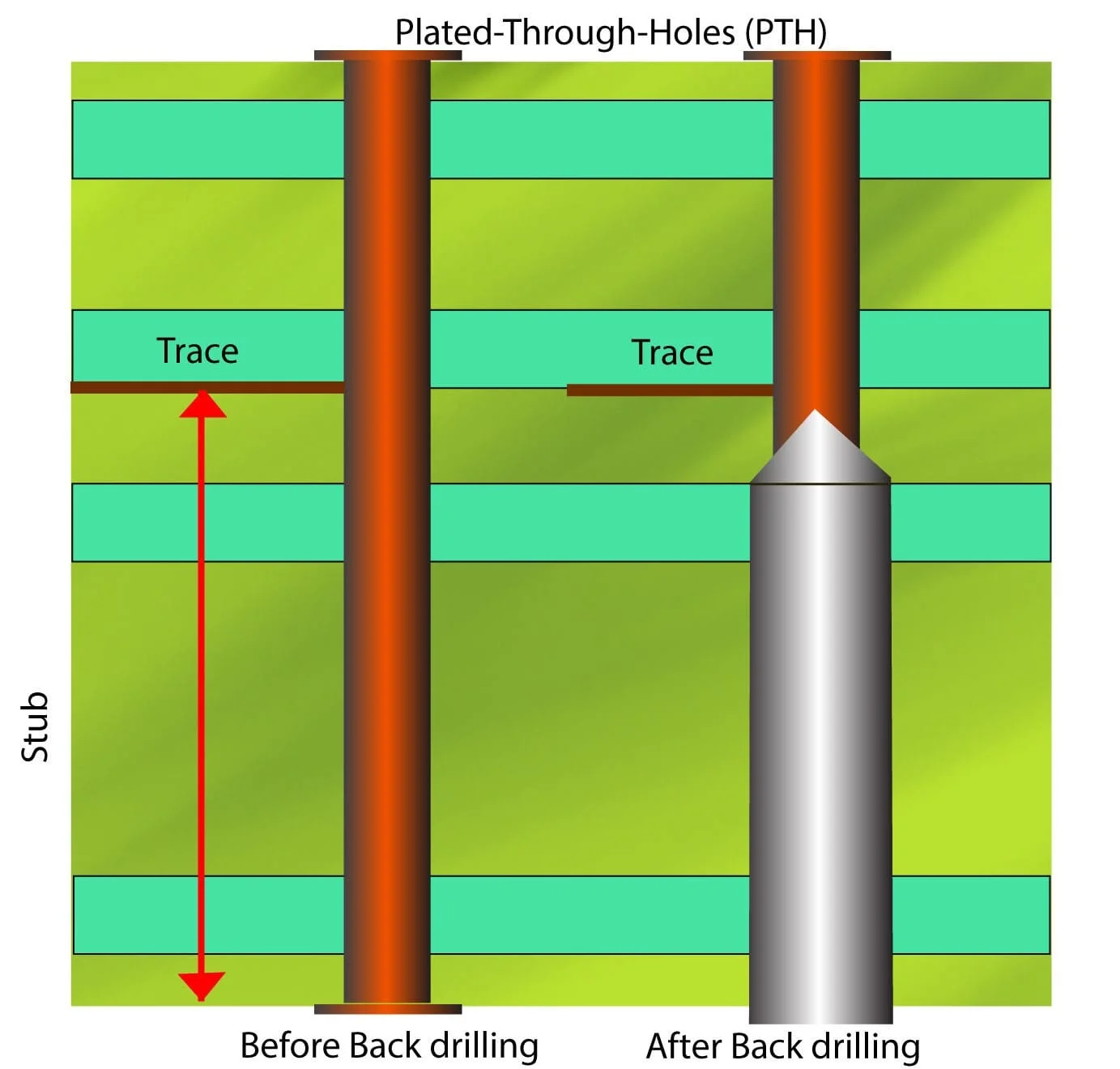

Backdrilling, also known as controlled depth drilling, is a specialized manufacturing technique used in printed circuit board (PCB) production. It involves drilling out the unused portion of a plated-through-hole (PTH) via after the initial drilling and plating process. This removes the "stub" — the section of the via that doesn't connect to any signal layer — which can cause signal integrity issues in high-speed designs.

In high-speed PCBs, these stubs act like tiny antennas, causing signal reflections and distortions. For example, at signal speeds above 5 Gbps, even a small stub of 0.010 inches can create impedance mismatches, leading to data errors. Backdrilling eliminates this problem by ensuring cleaner signal paths, making it a popular choice for applications like telecommunications, data centers, and high-performance computing.

Understanding the Cost of Backdrilling PCB

The cost of backdrilling PCB varies based on several factors, including the complexity of the design, the number of vias to be backdrilled, and the manufacturing capabilities required. On average, backdrilling can add 10-30% to the overall cost of PCB fabrication, depending on the board's specifications.

Here's a breakdown of what drives the cost:

- Number of Vias: Backdrilling is typically done on a per-via basis. A board with hundreds or thousands of vias will naturally cost more to backdrill than one with fewer vias.

- Layer Count: High-layer-count boards (e.g., 12+ layers) often require more precise backdrilling, increasing the time and cost of the process.

- Tolerance Requirements: Achieving tight depth tolerances (e.g., ±0.002 inches) requires advanced equipment and skilled labor, further driving up costs.

- Volume: Small production runs tend to have a higher per-unit cost for backdrilling compared to high-volume orders, where economies of scale can reduce expenses.

For instance, a medium-complexity PCB with 500 vias might see an additional cost of $0.05 to $0.10 per via for backdrilling, totaling an extra $25 to $50 per board. While this might seem small for a single board, it can add up quickly in large production runs.

Backdrilling Price Impact on Overall PCB Manufacturing

The price impact of backdrilling extends beyond just the drilling process itself. It influences other aspects of PCB manufacturing cost analysis, including design, testing, and potential rework. Let's break down these impacts:

1. Design Phase Costs

Backdrilling requires careful planning during the design stage. Engineers must specify which vias need backdrilling and define the exact depth for each. This often means additional time spent on design and simulation tools to ensure signal integrity, potentially increasing upfront costs by 5-10% for high-speed projects.

2. Manufacturing Complexity

Backdrilling adds a step to the manufacturing process, requiring specialized equipment and skilled operators. This can slow down production timelines slightly, especially for complex boards, and may increase labor costs.

3. Testing and Quality Assurance

After backdrilling, boards must undergo rigorous testing to ensure that the process hasn't damaged other layers or connections. This additional quality control step can add to the overall expense, particularly if defects are found and rework is needed.

ROI of Backdrilling: Does It Pay Off?

Calculating the ROI of backdrilling involves weighing the upfront costs against the long-term benefits. For many engineers and project managers, the key question is whether the performance improvements justify the added expense. Let's explore the potential returns:

Performance Benefits

Backdrilling significantly enhances signal integrity in high-speed designs. By removing via stubs, it reduces signal reflections and crosstalk, which can improve data transmission rates. For example, in a 10 Gbps system, backdrilling can reduce bit error rates (BER) from 10^-6 to 10^-12, a critical improvement for applications like 5G infrastructure or high-frequency trading systems.

Cost Savings from Reduced Failures

Poor signal integrity can lead to system failures, costly redesigns, or field repairs. By investing in backdrilling upfront, companies can avoid these expenses. For instance, a failed batch of PCBs in a telecommunications project could cost tens of thousands of dollars in lost time and materials. Backdrilling might prevent such issues, offering substantial savings over time.

Market Competitiveness

For industries where performance is a competitive edge, such as aerospace or medical electronics, backdrilling can be a differentiator. Delivering a product with superior reliability and speed can justify higher production costs if it leads to increased market share or customer satisfaction.

Cost-Benefit Analysis of Backdrilling

A thorough cost-benefit analysis of backdrilling requires looking at both tangible and intangible factors. Here's a step-by-step approach to evaluate whether backdrilling makes sense for your project:

Step 1: Assess Your Design Needs

Determine if your PCB design requires high-speed performance. If your application operates at speeds below 2.5 Gbps or doesn't demand strict signal integrity, backdrilling may not be necessary. However, for designs exceeding 5 Gbps or involving critical data transmission, the benefits often outweigh the costs.

Step 2: Calculate Additional Costs

Work with your manufacturing partner to get a detailed quote for backdrilling. Factor in not just the per-via cost but also any additional design or testing expenses. For example, a 20-layer board with 1,000 vias might incur an extra $100 per board for backdrilling and related processes.

Step 3: Estimate Performance Gains

Use simulation tools to model the impact of backdrilling on your design. Look at metrics like impedance control, signal loss, and crosstalk reduction. If backdrilling reduces signal loss by 20% or more, it could be a worthwhile investment for high-speed applications.

Step 4: Consider Long-Term Savings

Think about the potential cost of failures or redesigns if signal integrity issues arise. If backdrilling prevents even one major issue, the savings could easily offset the initial expense.

When Is Backdrilling Not Worth the Cost?

While backdrilling offers clear advantages for high-speed designs, it’s not always the right choice. Here are scenarios where the cost may not be justified:

- Low-Speed Applications: If your design operates at lower frequencies (e.g., below 1 Gbps), via stubs are unlikely to cause significant signal issues, making backdrilling unnecessary.

- Cost-Sensitive Projects: For budget-conscious projects where performance isn’t critical, the added expense of backdrilling might not align with project goals.

- Simple Designs: Boards with few layers or minimal via usage may not benefit enough from backdrilling to justify the cost.

Alternatives to Backdrilling: Balancing Cost and Performance

If the cost of backdrilling seems prohibitive, there are alternative approaches to manage signal integrity without breaking the budget:

- Blind and Buried Vias: These vias connect only the necessary layers, eliminating stubs without the need for backdrilling. However, they can be more expensive to manufacture in some cases.

- Optimized Routing: Careful design and routing can minimize the impact of via stubs by reducing their length or avoiding critical signal paths.

- Material Selection: Using low-loss dielectric materials can help mitigate signal integrity issues, potentially reducing the need for backdrilling.

How to Minimize Backdrilling Costs Without Sacrificing Quality

If you decide that backdrilling is necessary, there are ways to manage costs effectively:

- Selective Backdrilling: Only backdrill the vias that are critical to signal integrity, rather than every via on the board. This can reduce costs by 30-50% compared to full backdrilling.

- Partner with Experienced Manufacturers: Work with a fabrication house that has advanced backdrilling capabilities to ensure precision and minimize errors or rework.

- Plan Early: Incorporate backdrilling into the initial design phase to avoid costly redesigns or last-minute changes.

Conclusion: Making an Informed Decision on Backdrilling

Deciding whether backdrilling is worth the cost comes down to a careful evaluation of your project's requirements and budget. For high-speed, high-performance PCBs, the benefits of improved signal integrity and reduced failure rates often make backdrilling a smart investment. However, for simpler or cost-sensitive designs, the added expense may not deliver enough value.

By conducting a detailed PCB manufacturing cost analysis and considering the ROI of backdrilling, you can make an informed choice that balances performance and economics. Whether you opt for backdrilling or explore alternatives, the key is to align your decision with the specific needs of your application.

At ALLPCB, we’re committed to helping you navigate these complex decisions with expert guidance and high-quality manufacturing solutions. If you're weighing the cost-benefit analysis of backdrilling, our team is ready to provide tailored advice and support to ensure your project succeeds.

ALLPCB

ALLPCB