When deciding between a 1 oz copper PCB vs 2 oz copper PCB, the choice depends on your project's specific needs. If you're working on a standard, low-power application, a 1 oz copper PCB is often sufficient due to its lower cost and adequate performance for most consumer electronics. However, if your design requires higher current capacity, better thermal performance, or enhanced durability, a 2 oz copper PCB is the better option, despite its higher cost. In this detailed guide, we'll break down the differences in current capacity, cost, thermal performance, and key advantages to help you make an informed decision for your next PCB design.

Introduction to Copper Thickness in PCB Design

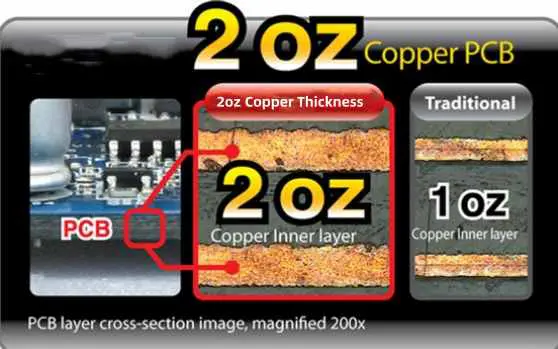

Copper thickness, measured in ounces per square foot (oz/ft2), plays a critical role in the performance of a printed circuit board (PCB). The "ounce" refers to the weight of copper spread over one square foot of the board, which directly correlates to its thickness. A 1 oz copper PCB has a thickness of about 1.4 mils (0.0014 inches), while a 2 oz copper PCB doubles that to approximately 2.8 mils (0.0028 inches). This difference may seem small, but it significantly impacts the board's ability to handle current, dissipate heat, and withstand mechanical stress.

Choosing between 1 oz and 2 oz copper is a common dilemma for engineers and designers. Each option has its strengths and trade-offs, and understanding these can help ensure your PCB performs reliably in its intended application. In this blog, we'll dive into a detailed comparison of 1 oz vs 2 oz PCB current capacity, cost, thermal performance, and the specific advantages of opting for a thicker copper layer.

Understanding 1 oz Copper PCB: The Industry Standard

A 1 oz copper PCB is the most common choice in the industry, often considered the default for many applications. This thickness is widely used in consumer electronics, such as smartphones, laptops, and household appliances, due to its balance of performance and affordability. The thinner copper layer is suitable for designs that don't require high current or intense heat dissipation.

For most low-to-medium power applications, a 1 oz copper PCB can carry enough current without issues. According to industry standards, a 1 oz copper trace with a width of 10 mils can handle approximately 1 ampere of current at a temperature rise of 10°C above ambient. This makes it ideal for small circuits or prototypes where cost savings are a priority.

However, 1 oz copper has limitations. It may struggle in high-power scenarios where traces need to carry more current or in environments where heat buildup is a concern. Overloading a 1 oz PCB can lead to trace overheating, increased resistance, and potential failure over time.

Exploring 2 oz Copper PCB: Enhanced Performance for Demanding Applications

A 2 oz copper PCB offers a thicker copper layer, providing better performance in several key areas. This option is often chosen for power electronics, industrial equipment, automotive systems, and other applications where higher current and better heat management are essential. The increased thickness reduces electrical resistance and allows the board to handle more power without overheating.

For example, a 2 oz copper trace of the same 10-mil width can handle roughly double the current of a 1 oz trace, up to 2 amperes, with the same 10°C temperature rise. This makes it a go-to choice for designs that involve power supplies, motor controllers, or LED lighting systems, where heat and current demands are higher.

While 2 oz copper provides clear benefits, it comes with trade-offs, such as increased cost and manufacturing complexity. Designers must weigh these factors against the performance gains to determine if the upgrade is necessary for their project.

1 oz vs 2 oz PCB Current Capacity: A Key Differentiator

One of the most significant differences in the 1 oz copper PCB vs 2 oz copper PCB comparison is their current-carrying capacity. Current capacity refers to the amount of electrical current a trace can handle without overheating or degrading over time. The thicker the copper, the lower the resistance, and the more current it can carry.

As mentioned earlier, a 1 oz copper trace can handle about 1 ampere per 10 mils of width at a 10°C temperature rise. In contrast, a 2 oz copper trace can manage around 2 amperes under the same conditions. This difference becomes even more pronounced with wider traces or higher temperature tolerances. For instance, at a 20°C temperature rise, a 1 oz trace might handle 1.5 amperes, while a 2 oz trace could manage up to 3 amperes.

This makes 2 oz copper PCBs the preferred choice for high-current applications. If your design involves power distribution or components that draw significant current, opting for 2 oz copper can prevent overheating and ensure long-term reliability. On the other hand, for low-power circuits like sensors or microcontrollers, 1 oz copper is often more than enough.

1 oz vs 2 oz PCB Cost: Budget Considerations

Cost is a critical factor when choosing between a 1 oz and 2 oz copper PCB. Generally, a 1 oz copper PCB is more affordable because it uses less material and is easier to manufacture. It’s the standard choice for many designs, so production processes are optimized for this thickness, further reducing costs. For small-scale projects or prototypes, sticking with 1 oz copper can save significant expenses without sacrificing performance.

In contrast, a 2 oz copper PCB costs more due to the increased amount of copper used and the additional manufacturing steps required. The thicker layer can also complicate processes like etching, as it takes longer to remove excess copper, potentially increasing labor and material costs. On average, a 2 oz copper PCB can be 20-30% more expensive than a 1 oz board, depending on the size and complexity of the design.

For budget-conscious projects, 1 oz copper is often the better choice unless the application specifically demands the enhanced capabilities of 2 oz copper. Always evaluate whether the performance gains justify the added expense before making a decision.

1 oz vs 2 oz PCB Thermal Performance: Managing Heat Effectively

Thermal performance is another area where 1 oz and 2 oz copper PCBs differ significantly. Heat dissipation is crucial in PCB design, as excessive heat can damage components, reduce lifespan, and affect overall reliability. The thicker copper in a 2 oz PCB provides better thermal conductivity, allowing it to spread and dissipate heat more effectively than a 1 oz PCB.

In high-power applications, components often generate substantial heat, and a 1 oz copper layer may struggle to manage it. This can lead to hot spots on the board, increasing the risk of failure. A 2 oz copper PCB, with its greater mass and lower thermal resistance, can handle higher temperatures and distribute heat more evenly across the board. For example, in a power supply circuit operating at 5 amperes, a 2 oz copper trace will typically experience a lower temperature rise compared to a 1 oz trace of the same width.

If your design operates in a high-temperature environment or includes heat-generating components like power transistors or high-current LEDs, a 2 oz copper PCB offers a clear advantage. However, for low-power applications where heat isn’t a major concern, a 1 oz copper PCB is usually sufficient and more cost-effective.

Advantages of 2 oz Copper PCB: When to Upgrade

While 1 oz copper PCBs are suitable for many applications, there are several distinct advantages of 2 oz copper PCBs that make them worth considering for specific projects. Here are the key benefits:

- Higher Current Capacity: As discussed, 2 oz copper can handle double the current of 1 oz copper for the same trace width, making it ideal for power-intensive designs.

- Improved Thermal Management: The thicker copper layer dissipates heat more effectively, reducing the risk of overheating and extending the lifespan of components.

- Enhanced Durability: A 2 oz copper PCB is more robust and less prone to damage from mechanical stress or repeated thermal cycles, which is beneficial in harsh environments like automotive or industrial settings.

- Better Signal Integrity: In high-frequency applications, thicker copper can reduce signal loss and impedance issues, leading to more stable performance.

- Support for Smaller Trace Widths: With higher current capacity, 2 oz copper allows for narrower traces in high-power designs, saving board space without sacrificing performance.

These advantages make 2 oz copper PCBs a preferred choice for applications like power converters, motor drivers, and renewable energy systems. If your project falls into one of these categories, the added cost of 2 oz copper is often justified by the performance and reliability gains.

Key Considerations for Choosing Between 1 oz and 2 oz Copper PCB

Selecting the right copper thickness for your PCB involves balancing performance requirements with budget constraints. Here are some factors to keep in mind when making your decision:

- Current Requirements: Calculate the maximum current your traces need to carry. If it exceeds the capacity of 1 oz copper, upgrading to 2 oz is necessary.

- Thermal Environment: Consider the operating temperature and heat generated by your components. For high-heat scenarios, 2 oz copper offers better protection.

- Budget: If cost is a major concern and your design doesn’t demand high current or thermal performance, stick with 1 oz copper to save money.

- Board Size and Complexity: Thicker copper can impact manufacturing precision, especially for fine traces or densely packed designs. Ensure your design rules align with the chosen thickness.

- Application Type: Consumer electronics often work fine with 1 oz copper, while industrial, automotive, or power applications may require 2 oz copper for reliability.

By carefully evaluating these factors, you can choose the copper thickness that best matches your project’s needs without overspending or compromising on performance.

Conclusion: Making the Right Choice for Your PCB Design

Deciding between a 1 oz copper PCB vs 2 oz copper PCB comes down to understanding your project’s specific requirements. A 1 oz copper PCB is a cost-effective, versatile option for most standard applications, offering sufficient performance for low-to-medium power circuits. On the other hand, a 2 oz copper PCB provides superior current capacity, thermal performance, and durability, making it the better choice for high-power or demanding environments despite its higher cost.

Whether you're designing a simple prototype or a complex power system, evaluating factors like 1 oz vs 2 oz PCB current capacity, cost, and thermal performance will guide you to the right decision. By choosing the appropriate copper thickness, you can ensure your PCB performs reliably and meets the needs of your application.

At ALLPCB, we’re committed to supporting your design journey with high-quality manufacturing solutions tailored to your specifications. Whether you opt for 1 oz or 2 oz copper, we’re here to help bring your ideas to life with precision and efficiency.

ALLPCB

ALLPCB