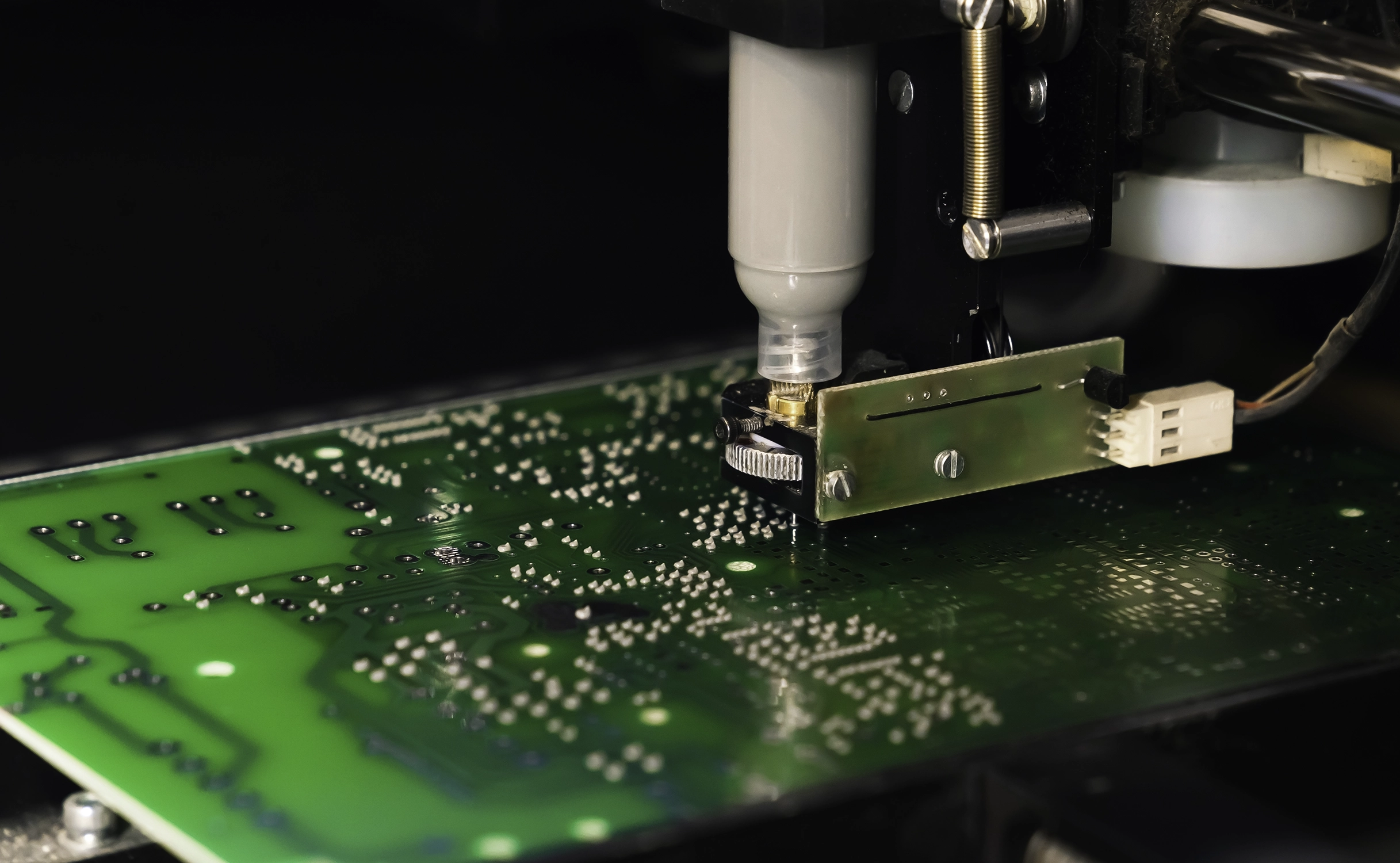

Maintaining a solder paste printing machine is essential for achieving consistent quality in Surface Mount Technology (SMT) assembly. Regular upkeep of components like the squeegee blade, stencil, and printer calibration ensures precise solder paste application, reducing defects and improving production efficiency. In this detailed guide, we'll explore the best practices for maintaining your solder paste printer, including a maintenance schedule, stencil cleaning tips, and more to keep your SMT equipment running smoothly.

Why Maintenance Matters for Solder Paste Printing Machines

In SMT manufacturing, the solder paste printing process is the foundation of a successful assembly. Over 60% of SMT defects can be traced back to issues during this stage, according to industry studies. A poorly maintained solder paste printer can lead to uneven paste application, bridging, or insufficient solder, all of which compromise the quality of the final product. By focusing on proper maintenance, you can minimize downtime, reduce material waste, and ensure reliable performance from your SMT equipment.

Essential Components of a Solder Paste Printer to Maintain

Before diving into maintenance tips, it’s important to understand the key parts of a solder paste printer that require regular attention. These components directly impact the quality of the printing process:

- Squeegee Blade: Responsible for spreading solder paste evenly across the stencil.

- Stencil: A thin metal sheet with openings that define where solder paste is applied on the PCB.

- Printer Calibration: Ensures alignment and pressure settings are accurate for consistent results.

- Supporting Mechanisms: Includes motors, belts, and sensors that keep the machine running smoothly.

Neglecting any of these areas can lead to costly errors. Let’s break down how to maintain each component for optimal performance.

1. Squeegee Blade Care for Flawless Paste Application

The squeegee blade is one of the most critical parts of a solder paste printer. It must apply even pressure to push solder paste through the stencil openings without leaving residue or causing damage. Here are key tips for maintaining your squeegee blade:

- Regular Cleaning: After every 4-6 hours of operation, clean the blade with a lint-free cloth and an approved solvent to remove solder paste buildup. Dried paste can cause uneven application and defects.

- Inspect for Wear: Check the blade edge for nicks or deformation weekly. A damaged blade can scrape the stencil or fail to spread paste evenly. Replace blades every 3-6 months, depending on usage.

- Proper Storage: When not in use, store the squeegee blade in a protective cover to prevent accidental damage or contamination.

By keeping the squeegee blade in top condition, you ensure consistent paste thickness, which is often targeted at 0.1 to 0.15 mm for most SMT applications.

2. Stencil Cleaning for Precision and Longevity

Stencil cleaning is a non-negotiable part of maintaining a solder paste printer. Residue on the stencil can block apertures, leading to incomplete paste deposits or misalignment. Follow these best practices for effective stencil cleaning:

- Automated Cleaning Systems: Many modern solder paste printers come with built-in under-stencil cleaning systems. Use a combination of wet, dry, and vacuum cycles every 5-10 prints to remove excess paste.

- Manual Cleaning: For manual cleaning, use a dedicated stencil cleaner or isopropyl alcohol with a soft, non-abrasive cloth. Avoid harsh chemicals that could damage the stencil’s surface.

- Frequency: Clean the stencil at least once per shift or after every 50 boards, whichever comes first, to prevent buildup.

- Storage: Store stencils vertically in a dust-free environment to avoid scratches or deformation.

A clean stencil can last for thousands of prints if maintained properly, saving costs and ensuring consistent solder paste application.

3. Printer Calibration for Accurate Alignment

Printer calibration is the backbone of precision in solder paste printing. Misalignment between the stencil and PCB can result in paste being applied outside the intended pads, leading to soldering defects. Here’s how to maintain proper calibration:

- Daily Checks: Verify the alignment of the stencil and PCB using the machine’s vision system or fiducial marks. Misalignment as small as 0.05 mm can cause issues.

- Pressure Settings: Ensure the squeegee pressure is set between 0.5 to 1.5 kg, depending on the paste type and stencil thickness. Too much pressure can damage the stencil, while too little can result in uneven paste.

- Speed Control: Adjust the printing speed to match the paste viscosity and stencil design. Typical speeds range from 20 to 50 mm/s for most applications.

- Professional Calibration: Schedule a full calibration by a certified technician every 6 months to ensure all mechanical and software settings are optimized.

Regular calibration not only improves accuracy but also extends the lifespan of your SMT equipment by reducing unnecessary strain on components.

4. Establishing a Maintenance Schedule for SMT Equipment

A well-planned maintenance schedule is the key to preventing unexpected breakdowns and ensuring consistent quality. Here’s a practical maintenance timeline for your solder paste printer:

- Daily: Clean the squeegee blade and stencil after each shift. Check alignment and pressure settings before starting production.

- Weekly: Inspect the squeegee blade for wear and tear. Perform a thorough cleaning of the printer’s internal components, including rails and sensors.

- Monthly: Lubricate moving parts like motors and belts with manufacturer-recommended grease to prevent friction. Check for software updates to improve machine performance.

- Quarterly: Conduct a detailed inspection of all mechanical parts. Replace worn components like belts or seals to avoid downtime.

- Semi-Annually: Schedule a professional service to recalibrate the machine and address any underlying issues.

Documenting each maintenance task in a log helps track the machine’s condition over time and identifies patterns that could indicate potential problems. A consistent maintenance schedule can reduce unexpected failures by up to 30%, based on industry reports.

5. Common Issues and Troubleshooting Tips

Even with regular maintenance, issues can arise with solder paste printers. Here are some common problems and how to address them:

- Uneven Paste Deposits: Often caused by a worn squeegee blade or incorrect pressure settings. Inspect and replace the blade if needed, and adjust pressure to the recommended range.

- Stencil Clogging: Results from inadequate cleaning. Increase cleaning frequency and ensure proper solvent use to clear apertures.

- Misalignment: Check the vision system or fiducial marks for errors. Recalibrate the machine if the issue persists.

- Paste Smearing: Usually due to excessive paste or high humidity. Reduce paste volume and control environmental conditions (ideal humidity is 40-60%).

Addressing these issues promptly prevents small problems from escalating into major production delays.

6. Environmental Factors in Solder Paste Printer Maintenance

The environment where your SMT equipment operates plays a significant role in its performance. Temperature, humidity, and cleanliness can impact solder paste behavior and machine longevity.

- Temperature: Maintain a range of 20-25°C in the production area. Extreme temperatures can affect paste viscosity, leading to inconsistent printing.

- Humidity: Keep humidity levels between 40-60% to prevent paste drying out or absorbing moisture, which can cause defects.

- Cleanliness: Use air filters and maintain a dust-free environment to avoid contamination of the stencil and paste.

Investing in environmental control systems can save thousands in defect-related costs over time.

7. Benefits of Proper Maintenance for SMT Equipment

Investing time and resources into maintaining your solder paste printer offers several long-term benefits:

- Improved Quality: Consistent solder paste application reduces defects like bridging or insufficient solder by up to 75%, as per industry data.

- Cost Savings: Regular maintenance extends the lifespan of components, reducing replacement costs and minimizing material waste.

- Reduced Downtime: A well-maintained machine experiences fewer breakdowns, keeping production on schedule.

- Enhanced Safety: Proper upkeep prevents mechanical failures that could pose risks to operators.

These advantages make maintenance not just a task, but a strategic part of your SMT production process.

Conclusion: Building a Culture of Maintenance

Maintaining a solder paste printing machine is not a one-time effort but an ongoing commitment to quality. By prioritizing squeegee blade care, stencil cleaning, printer calibration, and a structured maintenance schedule, you can ensure consistent results from your SMT equipment. Start by implementing the tips shared in this guide and tailor them to your specific production needs. Over time, these practices will become second nature, leading to higher efficiency, fewer defects, and a stronger bottom line for your manufacturing operations.

ALLPCB

ALLPCB