When it comes to designing a fitness tracker, one of the most critical decisions you'll make is selecting the right PCB substrate. The substrate material directly impacts the device's performance, durability, and cost. So, how do you choose the best PCB material for your fitness tracker design? In short, it depends on your specific requirements like size, flexibility, signal integrity, and budget. Common options include FR-4 PCB for cost-effectiveness, polyimide PCB for flexibility, and Rogers PCB for high-frequency performance. In this comprehensive guide, we'll dive deep into PCB material selection, exploring the best fitness tracker substrate options, and help you make an informed decision for your project.

Why PCB Material Selection Matters for Fitness Trackers

Fitness trackers are compact, wearable devices that monitor heart rate, steps, and other health metrics. They need to be lightweight, durable, and reliable under varying conditions like sweat, heat, and constant movement. The PCB substrate—the base material of the printed circuit board—plays a huge role in meeting these demands. A poor choice can lead to signal loss, overheating, or even device failure, while the right material ensures optimal performance and user satisfaction.

PCB material selection affects several key factors:

- Electrical Performance: The substrate influences signal integrity, especially for high-frequency data transmission in fitness trackers with Bluetooth or Wi-Fi.

- Mechanical Durability: Wearable devices need materials that resist bending, vibration, and environmental stress.

- Size and Weight: Compact designs require thin, lightweight substrates without compromising strength.

- Cost: Balancing performance with affordability is crucial for mass-produced consumer electronics.

With these factors in mind, let's explore the most popular PCB substrates for fitness tracker designs, including FR-4 PCB, polyimide PCB, and Rogers PCB, and see how they stack up.

Understanding PCB Substrates: The Foundation of Your Design

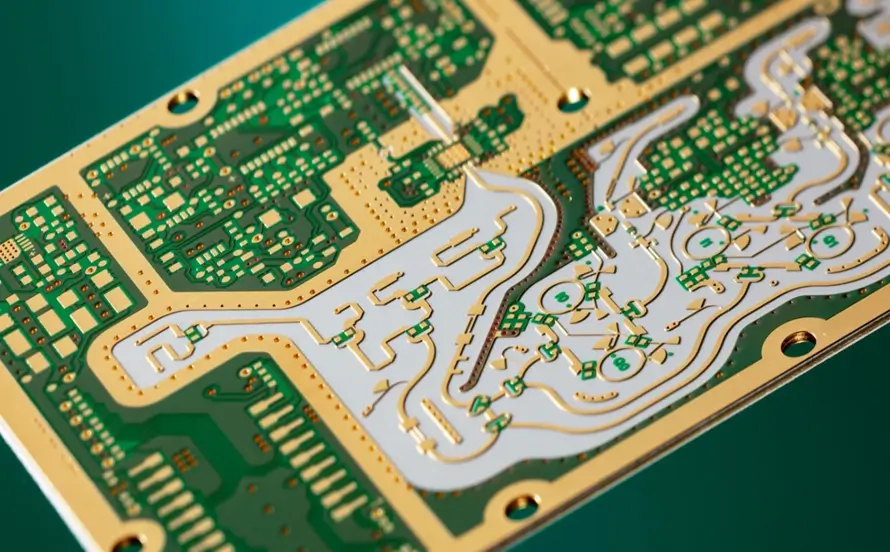

A PCB substrate is the insulating material that holds the copper traces and components of a circuit board. It acts as the backbone of your fitness tracker's electronics, determining how well the device handles electrical signals, heat, and physical stress. Different substrates have unique properties like dielectric constant (Dk), which affects signal speed, and thermal conductivity, which impacts heat dissipation.

Choosing the right fitness tracker substrate requires understanding your design needs. Are you prioritizing low cost for a budget-friendly product? Do you need flexibility for a curved or foldable design? Or is high-frequency performance critical for wireless features? Let's break down the top materials to help you decide.

FR-4 PCB: The Cost-Effective Workhorse

FR-4 PCB is the most widely used substrate material in the electronics industry, and for good reason. Made from a woven fiberglass cloth with an epoxy resin binder, FR-4 (Flame Retardant 4) is affordable, reliable, and versatile, making it a popular choice for fitness tracker designs where cost is a major concern.

Key Properties of FR-4 PCB

- Dielectric Constant (Dk): Around 4.5 at 1 MHz, suitable for low to medium frequency applications.

- Thermal Conductivity: Approximately 0.3 W/m·K, adequate for basic heat dissipation.

- Thickness: Available in various thicknesses (0.2 mm to 3.2 mm), supporting compact designs.

- Cost: Low, often less than $1 per square inch for standard boards.

Advantages for Fitness Trackers

FR-4 PCB shines in fitness trackers that don't require extreme flexibility or high-frequency performance. Its rigidity provides a stable base for mounting components like sensors and microcontrollers. Plus, its flame-retardant properties add a layer of safety for wearable devices. If your fitness tracker focuses on basic step counting or heart rate monitoring with minimal wireless features, FR-4 is often the best choice due to its balance of performance and price.

Limitations

However, FR-4 has drawbacks. It's not ideal for high-frequency signals (above 1 GHz) due to signal loss, which can be a problem for advanced fitness trackers with robust Bluetooth or GPS features. Additionally, its rigid nature limits its use in designs requiring flexibility or bending.

Polyimide PCB: Flexibility for Wearable Innovation

For fitness trackers that need to conform to the shape of a wristband or endure constant movement, polyimide PCB is a top contender. Polyimide is a flexible, high-performance plastic material known for its excellent mechanical and thermal properties, making it ideal for wearable electronics.

Key Properties of Polyimide PCB

- Dielectric Constant (Dk): Around 3.5 at 1 MHz, better than FR-4 for signal integrity.

- Thermal Conductivity: About 0.2 W/m·K, slightly lower than FR-4 but compensated by thin construction.

- Thickness: Extremely thin, often 0.05 mm to 0.1 mm, perfect for compact, lightweight designs.

- Cost: Higher than FR-4, typically $2-5 per square inch depending on specifications.

Advantages for Fitness Trackers

Polyimide PCB is the go-to material for flexible and foldable fitness tracker designs. Its ability to bend without breaking allows designers to create devices that wrap comfortably around the wrist or integrate into tight spaces. It also withstands high temperatures (up to 260°C), which is useful during manufacturing processes like soldering. For fitness trackers with curved displays or innovative form factors, polyimide offers unmatched versatility.

Limitations

The main downside of polyimide PCB is its cost, which can be several times higher than FR-4. Additionally, while it excels in flexibility, it may not provide the same level of rigidity for mounting heavier components, sometimes requiring a hybrid approach with rigid sections.

Rogers PCB: High-Frequency Performance for Advanced Features

For fitness trackers with advanced wireless capabilities, such as real-time data syncing over high-frequency bands, Rogers PCB materials stand out. These high-performance substrates are engineered for low signal loss and high-frequency applications, making them ideal for cutting-edge wearable tech.

Key Properties of Rogers PCB

- Dielectric Constant (Dk): Ranges from 2.2 to 10.2, depending on the specific Rogers material, optimized for high-frequency signals.

- Thermal Conductivity: Around 0.5-1.0 W/m·K, better than FR-4 and polyimide for heat management.

- Thickness: Available in thin layers, often 0.127 mm to 1.524 mm, supporting compact designs.

- Cost: Significantly higher, often $5-10 per square inch or more.

Advantages for Fitness Trackers

Rogers PCB materials are designed for high-frequency performance, with minimal signal loss even at frequencies above 10 GHz. This makes them perfect for fitness trackers with advanced Bluetooth, Wi-Fi, or GPS features that require clean, fast data transmission. They also offer excellent thermal stability, ensuring reliability in devices that might heat up during intensive use.

Limitations

The biggest barrier to using Rogers PCB is cost. It's often overkill for basic fitness trackers that don't need high-frequency capabilities. Additionally, these materials are less common and may require specialized manufacturing processes, adding to production complexity.

Comparing FR-4, Polyimide, and Rogers for Fitness Tracker Substrates

To help you with PCB material selection, here's a quick comparison of FR-4 PCB, polyimide PCB, and Rogers PCB based on key criteria for fitness tracker design:

| Material | Cost | Flexibility | High-Frequency Performance | Thermal Stability | Best Use Case |

|---|---|---|---|---|---|

| FR-4 PCB | Low | Rigid | Poor (up to 1 GHz) | Moderate | Basic fitness trackers |

| Polyimide PCB | Medium-High | Highly Flexible | Moderate (1-5 GHz) | High | Flexible, wearable designs |

| Rogers PCB | High | Rigid/Flexible Options | Excellent (10+ GHz) | High | Advanced, high-frequency trackers |

This table highlights that there's no one-size-fits-all solution. Your choice of fitness tracker substrate depends on the specific features and budget of your project.

How to Choose the Right PCB Substrate for Your Fitness Tracker

Selecting the best PCB material for your fitness tracker design involves weighing several factors. Here's a step-by-step guide to simplify the process:

- Define Your Requirements: Determine the key features of your fitness tracker. Does it need flexibility for a curved design? High-frequency performance for wireless connectivity? Or just basic functionality at a low cost?

- Set a Budget: Decide how much you're willing to spend on the PCB substrate. FR-4 is the most budget-friendly, while polyimide and Rogers materials cost more but offer specialized benefits.

- Consider Electrical Needs: If your device uses high-frequency signals (above 1 GHz), prioritize materials like Rogers with low dielectric loss. For basic sensors, FR-4 works fine.

- Evaluate Mechanical Demands: For flexible or foldable designs, polyimide is essential. For rigid, stable boards, FR-4 or Rogers can suffice.

- Test and Prototype: Before mass production, create prototypes with your chosen substrate to test performance under real-world conditions like heat, movement, and humidity.

By following these steps, you can narrow down your options and select a fitness tracker substrate that meets both technical and financial goals.

Additional Considerations in PCB Material Selection

Beyond the substrate itself, other factors can influence your fitness tracker design:

- Layer Count: Multi-layer PCBs allow for more complex circuitry in a compact space but increase costs. FR-4 and Rogers materials support multi-layer designs well.

- Environmental Resistance: Fitness trackers are exposed to sweat, moisture, and temperature changes. Ensure your substrate has adequate moisture resistance or consider protective coatings.

- Manufacturing Compatibility: Some materials, especially high-performance ones like Rogers, may require specialized fabrication processes. Verify that your manufacturing partner can handle your chosen substrate.

Future Trends in PCB Materials for Wearable Tech

As wearable technology evolves, so do PCB substrates. Researchers are developing new materials with enhanced flexibility, lower signal loss, and better thermal management. For instance, hybrid substrates combining rigid and flexible sections are becoming more common, allowing designers to use FR-4 for stable areas and polyimide for bendable parts in the same board. Additionally, eco-friendly substrates made from biodegradable materials are gaining attention for sustainable electronics.

Staying updated on these trends can give your fitness tracker design a competitive edge, ensuring it meets future consumer demands for performance and environmental responsibility.

Conclusion: Building Better Fitness Trackers with the Right Substrate

Choosing the right PCB substrate for your fitness tracker design is a balancing act between performance, cost, and durability. FR-4 PCB offers a cost-effective solution for basic devices, polyimide PCB excels in flexible, wearable applications, and Rogers PCB delivers top-tier performance for high-frequency needs. By carefully evaluating your project requirements and testing different materials, you can create a fitness tracker that stands out in a crowded market.

At ALLPCB, we're committed to helping you navigate PCB material selection with expert guidance and high-quality manufacturing services. Whether you’re prototyping a new fitness tracker or scaling up production, we've got the tools and expertise to bring your vision to life with the perfect fitness tracker substrate.

ALLPCB

ALLPCB