In the world of medical technology, precision and reliability are non-negotiable. High-layer-count PCBs (Printed Circuit Boards) play a vital role in ensuring that medical devices, from MRI machines to wearable health monitors, function flawlessly in critical applications. But what exactly makes these advanced PCBs so essential for medical equipment? In short, high-layer-count PCBs offer the complexity, signal integrity, and miniaturization needed to meet the stringent demands of healthcare technology.

This blog dives deep into the importance of high-layer-count PCBs in medical devices, exploring their design challenges, adherence to medical PCB standards, and specific applications like PCBs for MRI machines. Whether you're an engineer designing cutting-edge medical equipment or a procurement specialist seeking reliable PCB solutions, this guide will provide valuable insights to help you understand the critical role of these components.

What Are High-Layer-Count PCBs and Why Do They Matter in Medical Devices?

High-layer-count PCBs are circuit boards with multiple layers of conductive material, often ranging from 8 to 20 layers or more. These layers allow for intricate routing of electrical signals, accommodating complex circuits in a compact space. In medical devices, where space is often limited and functionality is paramount, these PCBs are indispensable.

Medical devices require exceptional precision and reliability because they directly impact patient safety. A single malfunction in a device like a pacemaker or an MRI machine can have life-threatening consequences. High-layer-count PCBs ensure that signals are transmitted with minimal interference, maintaining the accuracy of diagnostics and treatments. For instance, in high-frequency applications, these PCBs can manage impedance values as low as 50 ohms, ensuring clear signal transmission at speeds up to 10 Gbps or higher.

The Role of High-Layer-Count PCBs in Critical Medical Applications

Medical devices cover a wide range of applications, from portable glucose monitors to large-scale imaging systems. High-layer-count PCBs are tailored to meet the unique needs of each device, providing the necessary complexity and performance. Here are some key areas where these PCBs shine:

1. Diagnostic Equipment

Devices like MRI machines and CT scanners rely on high-layer-count PCBs to process vast amounts of data with precision. These systems often require boards with 12 or more layers to handle high-speed digital signals and analog inputs simultaneously. The ability to route signals without crosstalk or noise is critical for generating accurate images, which doctors use to make life-saving decisions.

2. Wearable Health Monitors

Wearable devices, such as heart rate monitors and smartwatches with health-tracking features, demand compact yet powerful PCBs. High-layer-count designs allow for the integration of sensors, processors, and wireless communication modules into a small footprint, ensuring both functionality and portability.

3. Implantable Devices

Pacemakers and neurostimulators are examples of implantable devices that depend on ultra-reliable PCBs. These applications require biocompatible materials and meticulous design to prevent failures. High-layer-count PCBs enable the dense packing of components while maintaining signal integrity, even in the challenging environment of the human body.

Medical PCB Standards: Ensuring Safety and Performance

The medical industry is governed by strict regulations to ensure patient safety and device reliability. High-layer-count PCBs used in medical devices must adhere to several standards that dictate design, manufacturing, and testing processes. Understanding these medical PCB standards is crucial for engineers and manufacturers.

Key Standards for Medical PCBs

- IPC-A-610 Class 3: This standard defines the highest level of quality for electronic assemblies, emphasizing reliability in critical applications. Medical PCBs often fall under this category due to their life-supporting roles.

- ISO 13485: This international standard focuses on quality management systems for medical device manufacturing. It ensures that every step, from design to delivery, meets rigorous safety and performance criteria.

- IEC 60601: This standard applies to the safety and effectiveness of medical electrical equipment. PCBs must be designed to prevent electrical hazards, such as short circuits or leakage currents, which could harm patients or operators.

Compliance with these standards often requires advanced manufacturing techniques, such as controlled impedance routing and thorough testing for thermal and mechanical stress. For example, a high-layer-count PCB for a medical device might undergo testing to withstand temperature ranges from -40°C to 85°C, ensuring functionality in diverse environments.

PCBs for MRI Machines: A Case Study in Precision

MRI (Magnetic Resonance Imaging) machines are among the most complex medical devices, relying heavily on high-layer-count PCBs for their operation. These machines use powerful magnetic fields and radio waves to create detailed images of the body, requiring PCBs that can handle high-frequency signals and extreme precision.

Why High-Layer-Count PCBs Are Essential for MRI Machines

MRI systems process signals in the range of 60 to 300 MHz, depending on the magnetic field strength (typically 1.5T or 3T). High-layer-count PCBs, often with 16 or more layers, are necessary to separate analog and digital signals, reducing noise and ensuring image clarity. Additionally, these PCBs must manage power distribution efficiently to support the machine’s high-energy components, like gradient coils and RF amplifiers.

The design of PCBs for MRI machines also involves shielding to prevent electromagnetic interference (EMI), which could distort images. Materials with low dielectric constants, such as PTFE-based laminates, are often used to maintain signal integrity at high frequencies.

Challenges in Manufacturing PCBs for MRI Machines

Manufacturing these PCBs is no small feat. The tight tolerances—sometimes as low as 0.1 mm for trace widths—and the need for precise layer alignment demand advanced fabrication processes. Furthermore, the boards must endure the strong magnetic fields of the MRI environment without degrading or interfering with the system’s performance.

Design Challenges of High-Layer-Count PCBs for Medical Devices

While high-layer-count PCBs offer immense benefits, designing and manufacturing them for medical applications comes with unique challenges. Addressing these hurdles is essential to ensure reliability and performance.

1. Signal Integrity

With multiple layers, the risk of signal crosstalk and noise increases. Designers must carefully plan trace routing and use techniques like ground planes and differential signaling to maintain signal integrity. For instance, achieving a controlled impedance of 100 ohms for differential pairs is often necessary in high-speed medical devices.

2. Thermal Management

Medical devices often operate continuously, generating heat that can affect PCB performance. High-layer-count PCBs require thermal vias and heat sinks to dissipate heat effectively, preventing component failure. Some designs incorporate copper thicknesses of up to 2 oz per layer to enhance heat distribution.

3. Miniaturization

As medical devices become smaller, PCBs must pack more functionality into limited space. This trend pushes the limits of layer stacking and via technology, such as microvias with diameters as small as 0.15 mm, to connect densely packed layers without compromising reliability.

Manufacturing Considerations for High-Layer-Count Medical PCBs

Producing high-layer-count PCBs for medical devices requires state-of-the-art manufacturing capabilities and strict quality control. Here are some key considerations:

- Material Selection: High-performance materials like FR-4 with high Tg (glass transition temperature) or polyimide are often used for their thermal stability and durability.

- Precision Drilling and Plating: Accurate drilling of vias and uniform copper plating are critical to prevent defects in multilayer boards.

- Testing and Validation: Every board undergoes rigorous testing, including automated optical inspection (AOI) and X-ray analysis, to detect internal defects like voids or misalignments.

These processes ensure that the final product meets the exacting demands of medical applications, where even a minor flaw can lead to catastrophic failure.

Benefits of Partnering with Experts for Medical PCB Solutions

Given the complexity and critical nature of high-layer-count PCBs in medical devices, collaborating with experienced PCB manufacturers is a smart choice. Experts in this field offer comprehensive services, from design consultation to prototype testing, ensuring that every board meets the required standards and specifications.

By leveraging advanced fabrication techniques and in-depth knowledge of medical PCB standards, such partnerships help reduce time-to-market while maintaining the highest levels of quality and reliability. This is especially important for applications like PCBs for MRI machines, where precision directly impacts diagnostic accuracy.

Future Trends in High-Layer-Count PCBs for Medical Devices

The medical field is evolving rapidly, and so are the technologies behind it. High-layer-count PCBs are at the forefront of several emerging trends:

- Integration of AI and IoT: Future medical devices will increasingly incorporate artificial intelligence and Internet of Things connectivity, requiring even more complex PCBs to handle data processing and communication.

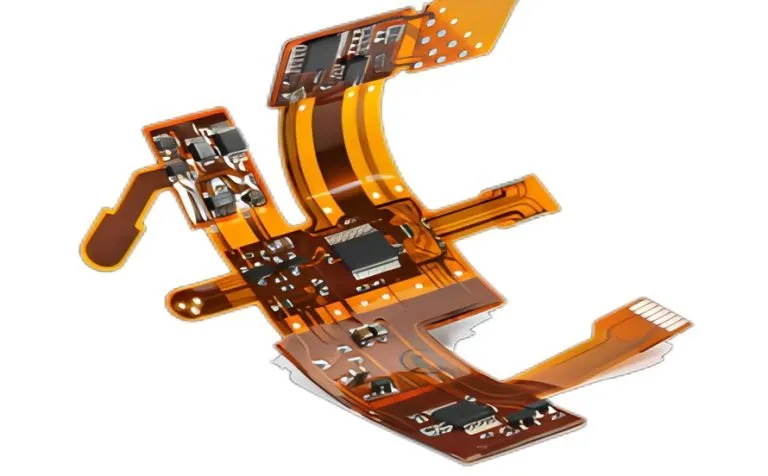

- Flexible and Rigid-Flex PCBs: These designs, often with high layer counts, are gaining traction for wearable and implantable devices due to their adaptability and compact form factor.

- Advanced Materials: Research into new materials with better thermal and electrical properties will further enhance the performance of high-layer-count PCBs in critical applications.

Conclusion

High-layer-count PCBs are the backbone of modern medical devices, providing the precision and reliability needed for critical applications. From ensuring signal integrity in MRI machines to enabling the miniaturization of wearable health monitors, these advanced circuit boards are indispensable in healthcare technology. By adhering to strict medical PCB standards and addressing design challenges, manufacturers can deliver solutions that meet the highest safety and performance requirements.

Understanding the role of high-layer-count PCBs in medical devices equips engineers and decision-makers with the knowledge to choose the right solutions for their projects. As technology continues to advance, these PCBs will play an even greater role in shaping the future of medical innovation, ensuring better outcomes for patients worldwide.

ALLPCB

ALLPCB