In the rapidly evolving world of electronics, E-Readers have become a staple for book lovers who value portability and innovation. A key component driving the next generation of these devices is the flexible PCB (Printed Circuit Board). If you're searching for insights on E-Reader flexible PCB design, bendable PCB E-Reader solutions, or flexible display integration, you've come to the right place. This blog dives deep into the essentials of designing flexible PCBs for E-Readers, covering materials, bending radius considerations, and integration techniques to help engineers and designers create cutting-edge devices.

At its core, designing a flexible PCB for an E-Reader involves balancing durability, functionality, and compactness. These boards must withstand bending and folding while maintaining reliable performance for displays and other components. Below, we’ll explore the critical aspects of this process, offering practical tips and detailed guidance for creating innovative E-Reader designs.

What Are Flexible PCBs and Why Are They Essential for E-Readers?

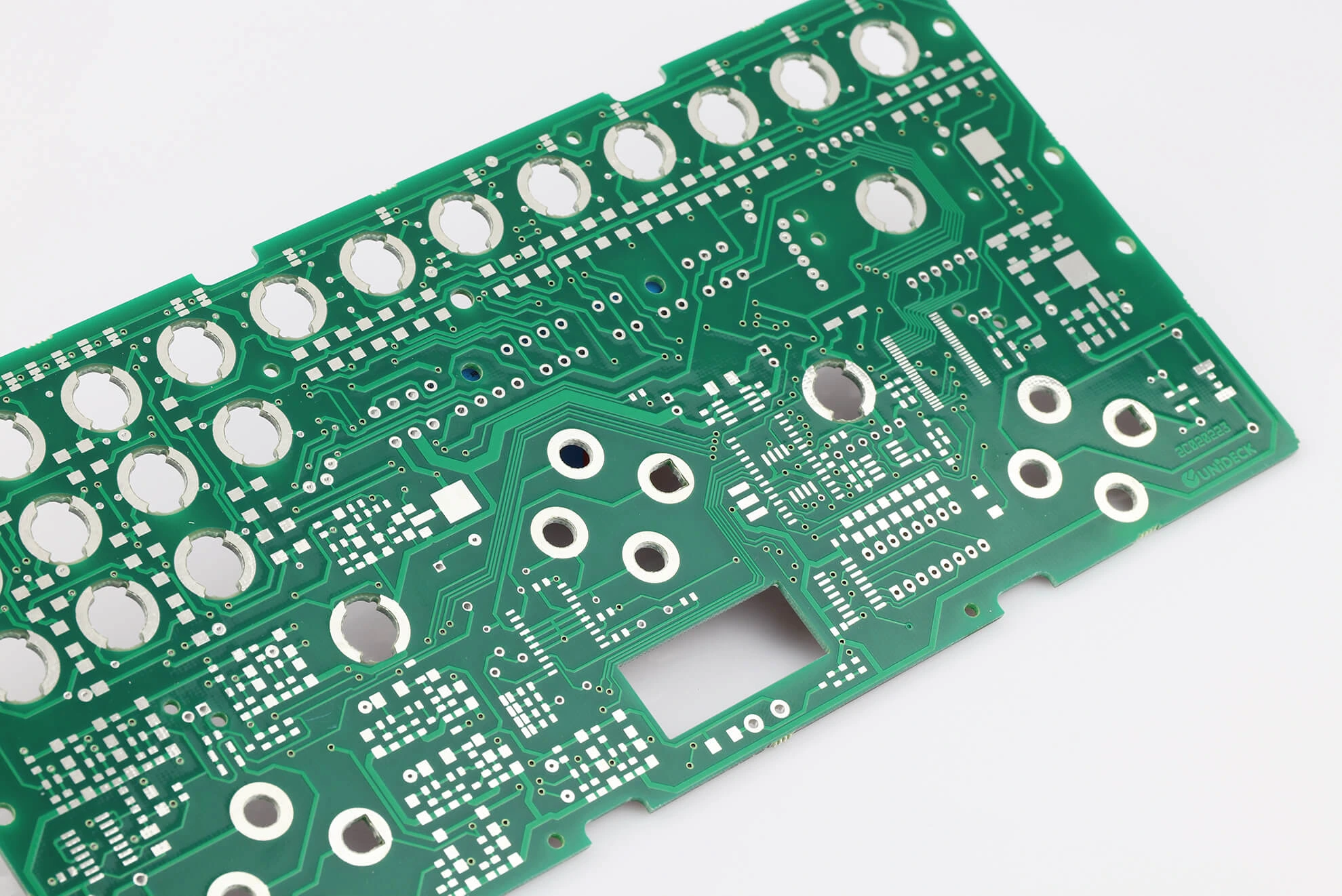

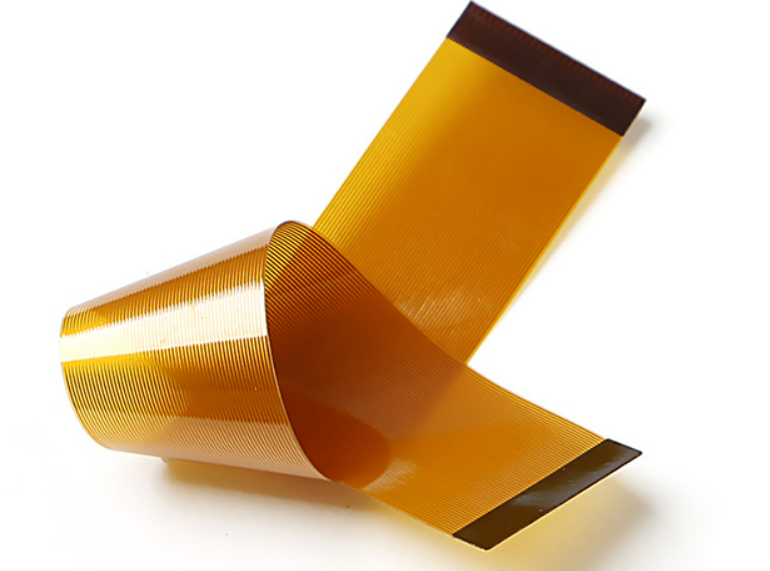

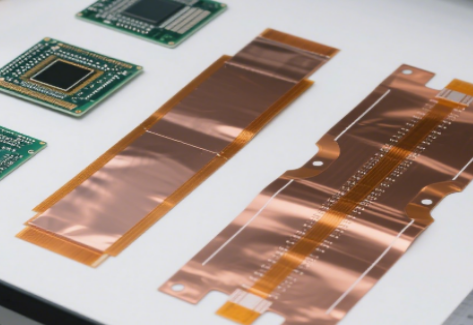

Flexible PCBs are thin, lightweight circuit boards made from pliable materials that allow them to bend, twist, or fold without breaking. Unlike traditional rigid PCBs, these boards can conform to unique shapes, making them ideal for compact and portable devices like E-Readers. The rise of bendable and foldable E-Reader designs has made flexible PCBs a cornerstone of modern electronics, enabling sleeker form factors and enhanced user experiences.

For E-Readers, flexible PCBs are essential because they support flexible display integration. They allow the device to house bendable screens, reduce overall weight, and fit complex circuitry into tight spaces. Whether it's a foldable E-Reader or a lightweight model with a curved screen, these PCBs provide the foundation for innovation in design and functionality.

Key Materials for Flexible PCB Design in E-Readers

Choosing the right flexible PCB material is critical for ensuring durability and performance in E-Reader designs. The materials must support repeated bending, resist wear, and maintain electrical integrity. Below are the most commonly used materials in flexible PCB manufacturing:

- Polyimide (PI): This is the go-to material for most flexible PCBs due to its excellent thermal stability and flexibility. Polyimide can withstand temperatures up to 400°C and offers a high tensile strength, making it perfect for E-Readers that may experience frequent bending.

- Polyester (PET): A more cost-effective option, polyester is often used in less demanding applications. While it’s not as durable as polyimide under extreme conditions, it’s still suitable for lightweight E-Reader designs with minimal bending requirements.

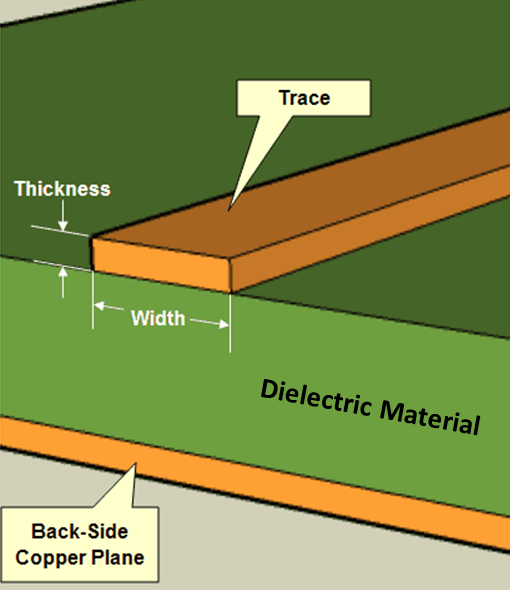

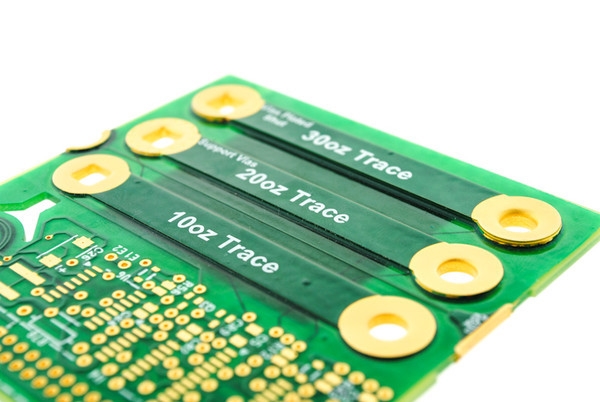

- Copper Foil: Thin copper layers are used for conductive traces in flexible PCBs. Rolled annealed copper is preferred for its flexibility, allowing traces to bend without cracking. Typical thicknesses range from 12 to 35 micrometers for optimal performance.

- Adhesives and Coverlays: These materials protect the circuitry and bond layers together. Acrylic or epoxy-based adhesives are common, while coverlays made of polyimide provide insulation and protection against environmental factors.

When selecting materials for an E-Reader, consider the expected bending cycles and environmental conditions. For instance, a foldable E-Reader may require a polyimide base with a high flex cycle rating (often exceeding 100,000 cycles) to ensure longevity.

Understanding E-Reader PCB Bending Radius

One of the most critical factors in E-Reader PCB bending radius design is determining the minimum bend radius the board can handle without damaging traces or components. The bending radius refers to the smallest curve a flexible PCB can make before risking mechanical failure or signal degradation.

For E-Readers, where space is limited and folding or curving is often required, designers must carefully calculate the bending radius. A general rule of thumb is that the bend radius should be at least 10 times the thickness of the PCB for dynamic bending (repeated folding). For static bending (a one-time fold during assembly), a radius of 6 times the thickness may suffice. For example, a 0.1 mm thick flexible PCB should have a minimum dynamic bend radius of 1 mm.

Key considerations for bending radius include:

- Layer Count: Multi-layer flexible PCBs are thicker and require a larger bend radius. A single-layer board might bend tighter than a 4-layer design.

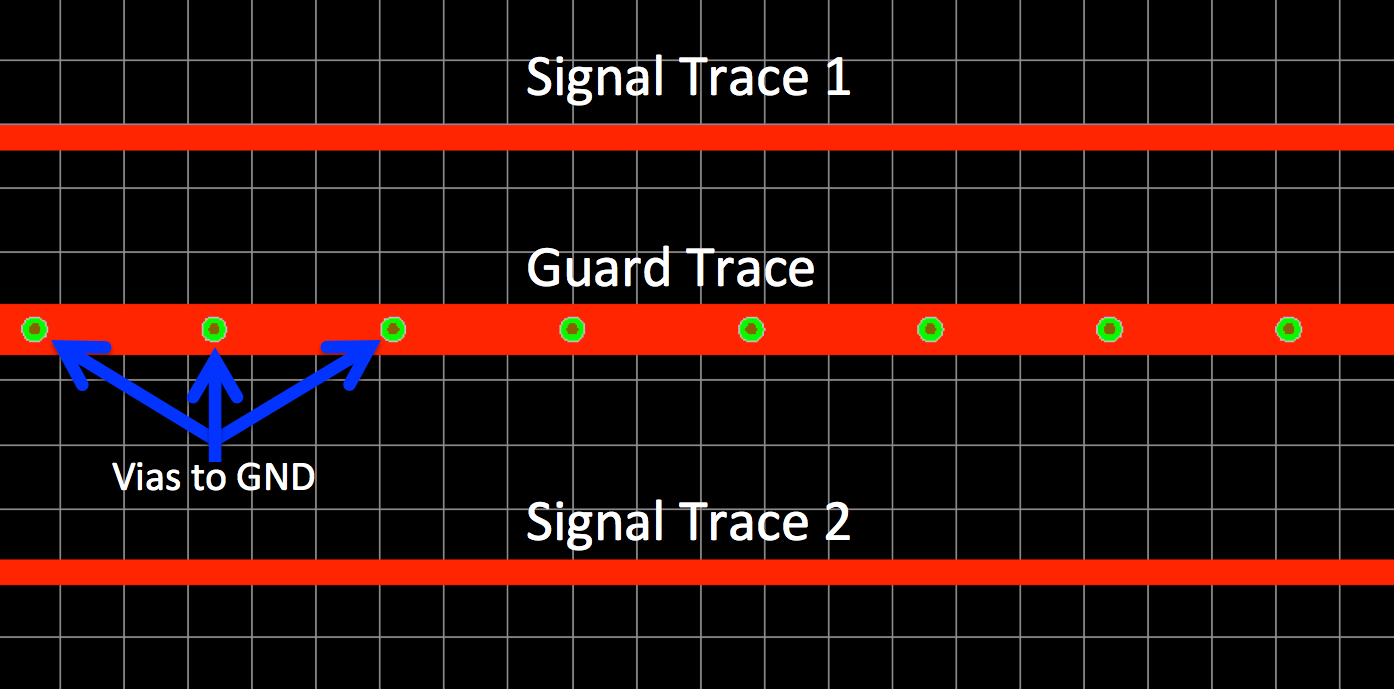

- Trace Layout: Traces running perpendicular to the bend are more prone to cracking. Design traces parallel to the bend line to minimize stress.

- Material Flexibility: As mentioned earlier, materials like polyimide offer better flexibility, allowing for tighter bends compared to polyester.

By optimizing the bending radius, designers can prevent issues like trace fractures or delamination, ensuring the E-Reader remains functional even after thousands of folds.

Design Techniques for Bendable PCB E-Reader Solutions

Creating a bendable PCB E-Reader requires specialized design techniques to ensure reliability and performance. Here are some actionable strategies for engineers working on E-Reader projects:

1. Optimize Trace Routing

Avoid sharp corners in trace routing, as they can create stress points during bending. Instead, use curved or rounded traces. Additionally, stagger traces in multi-layer designs to reduce stress concentration in a single area.

2. Use Flexible Zones Strategically

Not all parts of a PCB need to be flexible. Hybrid designs, often called rigid-flex PCBs, combine rigid sections for mounting components like processors with flexible zones for bending. In an E-Reader, the display connection area might be flexible, while the main control board remains rigid.

3. Minimize Component Stress

Place components away from bend areas to avoid mechanical stress. If components must be in flexible zones, use smaller, lightweight parts and secure them with underfill or adhesives to prevent detachment.

4. Account for Signal Integrity

Bending can affect signal integrity, especially for high-speed signals. Maintain consistent impedance by keeping trace widths uniform and avoiding tight bends. For E-Reader displays, where refresh rates might reach 60 Hz or higher, signal integrity is crucial to prevent flickering or data loss. Typical impedance values for flexible PCB traces range from 50 to 100 ohms, depending on the application.

These techniques help create robust designs that can handle the physical demands of a bendable E-Reader while maintaining electrical performance.

Challenges and Solutions in Flexible Display Integration

Flexible display integration is a game-changer for E-Readers, allowing for foldable screens and innovative form factors. However, integrating a flexible display with a PCB poses unique challenges. Here’s how to address them:

Challenge 1: Display Connection Reliability

Flexible displays require a secure yet bendable connection to the PCB. Traditional connectors can fail under repeated bending. Solution: Use anisotropic conductive film (ACF) bonding or flexible flat cables (FFC) designed for dynamic bending. These methods ensure a reliable connection even after thousands of cycles.

Challenge 2: Stress on Display Layers

Bending a display can stress its layers, leading to cracks or pixel damage. Solution: Align the display’s neutral axis (the plane that experiences no strain during bending) with the PCB’s bend line. This minimizes stress on both components.

Challenge 3: Power Consumption and Heat

Flexible displays and PCBs can generate heat, especially in compact E-Reader designs with limited ventilation. Solution: Use low-power components and incorporate thermal vias or heat dissipation layers in the PCB to manage temperature. For instance, keeping power consumption below 1 watt for display drivers can reduce heat buildup.

By tackling these challenges, designers can achieve seamless integration of flexible displays, creating E-Readers that are both innovative and durable.

Testing and Validation for Flexible PCBs in E-Readers

Before mass production, rigorous testing is essential to ensure a flexible PCB meets the demands of an E-Reader. Key tests include:

- Bend Cycle Testing: Simulate thousands of bending cycles to assess durability. A typical target for foldable E-Readers is 50,000 to 100,000 cycles without failure.

- Environmental Testing: Expose the PCB to temperature extremes (e.g., -20°C to 60°C) and humidity levels (up to 85% RH) to ensure reliability in various conditions.

- Signal Integrity Testing: Measure signal loss or interference during bending. Tools like time-domain reflectometry (TDR) can help identify impedance mismatches or delays.

Validation ensures that the PCB can handle real-world use, from frequent folding to accidental drops, without compromising the E-Reader’s performance.

Future Trends in E-Reader Flexible PCB Design

The future of E-Reader flexible PCB design is bright, with emerging technologies pushing the boundaries of what’s possible. Some trends to watch include:

- Thinner Materials: Advances in material science are leading to even thinner flexible substrates, reducing the overall weight of E-Readers while maintaining durability.

- Stretchable Electronics: Beyond bending, stretchable PCBs could enable E-Readers with expandable screens or unique shapes.

- Integrated Sensors: Future flexible PCBs may incorporate touch or pressure sensors directly into the board, eliminating the need for separate components and further reducing device thickness.

These innovations promise to make E-Readers more versatile, durable, and user-friendly, opening new possibilities for design and functionality.

Conclusion: Innovating with Flexible PCBs for E-Readers

Designing flexible PCBs for E-Readers is all about bending the rules—both literally and figuratively. By leveraging the right flexible PCB material, optimizing the E-Reader PCB bending radius, and mastering flexible display integration, engineers can create devices that are lightweight, durable, and cutting-edge. Whether you're working on a bendable PCB E-Reader or exploring new form factors, the techniques and insights shared in this blog provide a roadmap for success.

At ALLPCB, we’re committed to supporting your journey in E-Reader flexible PCB design. With the right materials, design strategies, and testing protocols, you can bring your innovative E-Reader concepts to life. Let’s shape the future of portable reading devices together, one flexible circuit at a time.

ALLPCB

ALLPCB