Selecting the right PCB materials for smart city sensors is critical to ensure reliability, performance, and longevity in diverse and often challenging environments. Whether you're designing sensors for traffic monitoring, environmental tracking, or energy management, the materials you choose can make or break your project. In this comprehensive guide, we'll walk you through the essentials of PCB material selection, focusing on key considerations like high-temperature PCB options, flexible PCB material, RF PCB material, and environmental PCB material choices. Let's dive into the details to help you make informed decisions for your smart city applications.

Why PCB Material Selection Matters for Smart City Sensors

Smart city sensors are at the heart of urban innovation, collecting data to improve infrastructure, reduce energy waste, and enhance public safety. These sensors often operate in harsh conditions—think extreme heat, humidity, or constant vibration. The wrong PCB material can lead to signal loss, thermal breakdown, or mechanical failure, compromising the entire system. By focusing on the right materials, you ensure durability, accuracy, and efficiency. This guide will break down the specific material properties needed for different sensor applications, helping engineers and designers optimize their designs.

Key Factors in PCB Material Selection for Smart City Sensors

Before diving into specific material types, it's important to understand the core factors that influence PCB material selection. These factors are shaped by the unique demands of smart city sensors, which often require a balance of performance and resilience.

1. Operating Environment

Smart city sensors are exposed to a wide range of environmental conditions. For outdoor sensors, materials must withstand temperature swings (from -40°C to 85°C or higher), moisture, and UV radiation. Indoor sensors might face less extreme conditions but still need to resist dust and potential chemical exposure. Choosing environmental PCB material with high resistance to these factors is essential for long-term reliability.

2. Electrical Performance

Sensors often transmit data wirelessly or handle high-frequency signals, especially in applications like 5G-enabled traffic systems. Materials with low dielectric constant (Dk) and low dissipation factor (Df) are critical for minimizing signal loss. For example, a typical Dk value for high-frequency applications should be below 3.5, while Df should be under 0.005 to ensure clear signal transmission at frequencies above 1 GHz.

3. Mechanical Durability

Sensors in smart cities might be subject to vibration (e.g., in road infrastructure) or need to fit into compact, curved spaces (e.g., wearable health monitors). This is where flexible PCB material or rigid-flex options come into play, offering both strength and adaptability without cracking under stress.

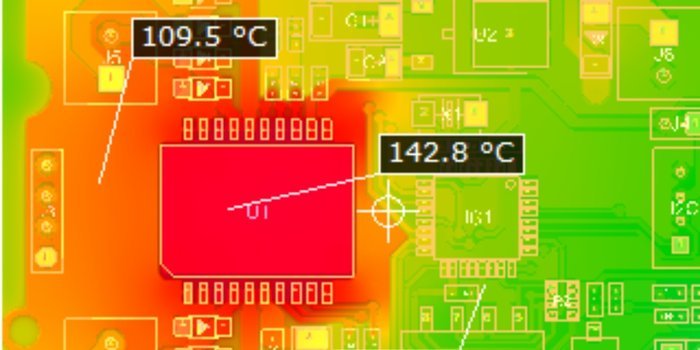

4. Thermal Management

High temperatures can degrade sensor performance, especially in densely packed urban setups or during summer heatwaves. High-temperature PCB materials with a high glass transition temperature (Tg)—ideally above 170°C—can prevent warping or delamination under heat stress.

Types of PCB Materials for Smart City Sensors

Now that we've covered the key factors, let's explore the specific materials that suit different smart city sensor needs. Each material type addresses particular challenges, from flexibility to high-frequency performance.

1. High-Temperature PCB Materials

For sensors operating in hot climates or near heat-generating equipment, high-temperature PCB materials are a must. These materials are designed to handle elevated temperatures without losing structural integrity or electrical performance.

- Polyimide: Known for its excellent thermal stability, polyimide can operate in temperatures up to 260°C. It's ideal for sensors in industrial zones or near engines, with a Tg often exceeding 250°C.

- High-Tg FR-4: A more cost-effective option compared to polyimide, high-Tg FR-4 offers a Tg of 170°C to 180°C. It's suitable for moderate high-temperature environments, like rooftop weather sensors.

- Application Example: A temperature sensor on a smart grid transformer might use polyimide to withstand continuous heat exposure, ensuring accurate readings over years.

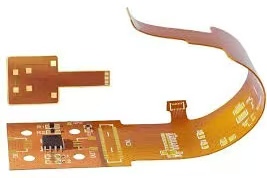

2. Flexible PCB Materials

Smart city sensors often need to fit into unconventional spaces or endure constant movement. Flexible PCB material provides the bendability required for such applications while maintaining performance.

- Polyimide (Again): Besides its thermal resistance, polyimide is highly flexible, making it perfect for wearable sensors or curved installations in streetlights. It can bend to a radius as small as 0.5 mm without damage.

- PET (Polyethylene Terephthalate): A cheaper alternative for less demanding applications, PET offers decent flexibility but is limited to lower temperatures (up to 120°C).

- Application Example: A flexible PCB made of polyimide could be used in a wearable air quality sensor, allowing it to conform to a wristband design without cracking.

3. RF PCB Materials for High-Frequency Performance

Many smart city sensors rely on wireless communication, requiring materials optimized for radio frequency (RF) signals. RF PCB material selection focuses on low signal loss and consistent performance at high frequencies.

- PTFE-Based Laminates: With a Dk as low as 2.1 and Df below 0.0009, PTFE materials are ideal for high-frequency applications like 5G sensors. They minimize signal attenuation even at frequencies up to 10 GHz.

- Rogers Materials: Known for their stability in RF environments, these laminates offer Dk values between 2.2 and 3.0, making them suitable for radar-based traffic sensors.

- Application Example: An RF PCB in a smart parking sensor might use PTFE to ensure reliable signal transmission over long distances, avoiding interference in crowded urban areas.

4. Environmental PCB Materials for Harsh Conditions

Outdoor smart city sensors face rain, pollution, and UV exposure, necessitating environmental PCB material with protective properties.

- Epoxy-Based Materials: Often combined with protective coatings, epoxy laminates resist moisture and chemical corrosion. They're a good fit for air quality sensors exposed to urban pollutants.

- Ceramic-Filled Laminates: These offer superior resistance to humidity and thermal shock, ideal for sensors in coastal cities with high salt content in the air.

- Application Example: A weather station sensor in a coastal smart city might use ceramic-filled laminates to prevent corrosion from salty air, ensuring accurate humidity readings.

How to Choose the Right PCB Material for Your Smart City Sensor

With so many options, narrowing down the best material for your project can feel overwhelming. Here's a step-by-step approach to simplify PCB material selection.

Step 1: Define Sensor Requirements

Start by listing the specific needs of your sensor. Does it need to handle high frequencies for wireless data transfer? Will it be exposed to extreme heat or moisture? Understanding these requirements sets the foundation for material choice.

Step 2: Match Material Properties to Needs

Refer to the material types discussed earlier. For instance, if your sensor requires flexibility and heat resistance, polyimide might be the best choice. If RF performance is critical, prioritize low-Dk materials like PTFE.

Step 3: Consider Cost and Availability

High-performance materials like PTFE or ceramic-filled laminates can be expensive. Balance performance with budget constraints. For less demanding applications, standard FR-4 or PET might suffice without breaking the bank.

Step 4: Test and Validate

Before full-scale production, prototype your design with the chosen material. Test it under real-world conditions to confirm it meets expectations for thermal, electrical, and mechanical performance.

Common Challenges in PCB Material Selection and How to Overcome Them

Even with careful planning, challenges can arise during PCB material selection. Here are some common issues and solutions tailored for smart city sensor projects.

Challenge 1: Balancing Cost and Performance

High-end materials often come with a steep price tag. To address this, consider hybrid designs—use premium materials only in critical areas (like RF sections) and standard materials elsewhere.

Challenge 2: Signal Integrity in High-Density Urban Areas

Urban environments are full of electromagnetic interference. Opt for RF PCB material with excellent shielding properties and low signal loss to maintain data accuracy.

Challenge 3: Long-Term Durability

Sensors need to last years without maintenance. Focus on environmental PCB material with proven resistance to weathering, and consider adding conformal coatings for extra protection against moisture and dust.

Future Trends in PCB Materials for Smart City Sensors

As smart cities evolve, so do the materials used in sensor PCBs. Here are a few trends shaping the future of PCB material selection.

- Sustainable Materials: Eco-friendly laminates made from bio-based resins are gaining traction, reducing the environmental impact of PCB production.

- Nanomaterials: Innovations in nanotechnology are leading to thinner, lighter materials with superior thermal and electrical properties, ideal for compact sensors.

- 5G and Beyond: With the rollout of 5G and future 6G networks, demand for advanced RF PCB material will grow, pushing the development of even lower-loss laminates.

Conclusion: Making Informed Choices for Smart City Sensors

Choosing the right PCB materials for smart city sensors is a complex but crucial task. By focusing on factors like thermal resistance, flexibility, RF performance, and environmental durability, you can select materials that ensure your sensors operate reliably in any condition. Whether you need a high-temperature PCB for industrial monitoring, a flexible PCB material for wearable devices, or an RF PCB material for wireless communication, understanding the strengths of each option is key. At ALLPCB, we’re committed to supporting your projects with high-quality materials and expertise tailored to smart city innovations. Use this guide as your roadmap to build sensors that power the cities of tomorrow.

ALLPCB

ALLPCB