In the fast-paced world of PCB manufacturing, precision is everything. If you're looking to optimize your Surface Mount Technology (SMT) assembly process, understanding SMT stencil capabilities and the role of panel fiducials in automated stencil machines is crucial. This blog dives deep into how proper fiducial positioning enhances component placement and explores effective layout techniques to streamline your production. Whether you're a seasoned engineer or new to SMT assembly, you'll find practical insights to improve accuracy and efficiency.

At its core, SMT stencil technology paired with precise fiducial placement ensures that solder paste is applied accurately on the PCB, setting the foundation for flawless component mounting. In the sections below, we’ll break down the essentials of stencil capabilities, the importance of fiducials, and how to integrate these elements into an automated workflow for maximum results.

What Are SMT Stencils and Their Capabilities?

SMT stencils are thin sheets, typically made of stainless steel, used to apply solder paste onto a PCB’s surface during the assembly process. Their primary function is to ensure that the paste is deposited in the exact locations where components will be placed. The capabilities of modern SMT stencils have evolved significantly, thanks to advancements in laser cutting and material technology.

High-quality stencils can achieve aperture tolerances as tight as ±5 microns, allowing for precise solder paste deposition even on densely populated boards with fine-pitch components. They come in two main forms: framed and frameless. Framed stencils are designed for automated stencil machines, offering stability and compatibility with high-speed production lines. Frameless stencils, on the other hand, are more suited for manual or low-volume applications due to their lighter weight and flexibility.

Modern stencil manufacturing also supports a variety of thicknesses, typically ranging from 0.1mm to 0.2mm, depending on the component size and solder paste requirements. For instance, thinner stencils (0.1mm) are ideal for ultra-fine pitch components, while thicker ones (0.15mm to 0.2mm) are better for larger components requiring more paste volume. These capabilities make SMT stencils adaptable to a wide range of PCB designs, ensuring optimal results in diverse manufacturing scenarios.

The Role of Panel Fiducials in SMT Assembly

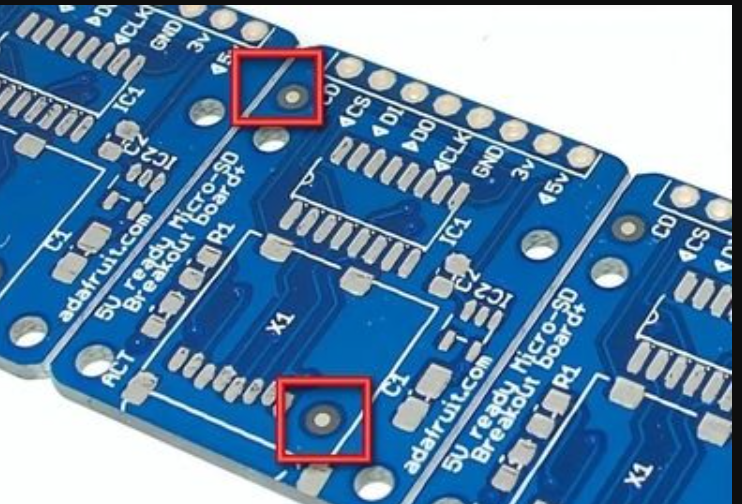

Panel fiducials are small reference marks or points on a PCB or panel that help machines identify the exact position and orientation of the board during manufacturing. These marks are critical for automated stencil machines as they enable precise alignment between the stencil and the PCB, ensuring accurate solder paste application.

Fiducials are typically circular in shape with a diameter of about 1mm, though this can vary based on the machine's vision system requirements. They are often made of bare copper or covered with a contrasting material to make them easily detectable by optical systems. In automated SMT processes, fiducials act as anchors for the machine’s vision system to calibrate its coordinates before printing or component placement.

Without properly placed fiducials, even the most advanced automated systems can misalign, leading to defects like solder bridges or insufficient paste, which can cause component failure. Therefore, understanding how to position these marks is a game-changer for achieving high yield rates in PCB assembly.

Why Fiducial Positioning Matters for Automated Stencil Machines

In an automated stencil machine, precision alignment is non-negotiable. These machines rely on vision systems to scan fiducials and adjust the stencil’s position relative to the PCB. Incorrect fiducial placement can lead to misalignment, resulting in uneven solder paste distribution and, ultimately, defective boards.

For optimal performance, fiducials should be placed in areas that are easily accessible to the machine’s cameras, typically near the corners of the PCB or panel. A common practice is to position at least two fiducials diagonally opposite each other on the board to provide a clear reference for rotation and scaling. For larger panels, additional fiducials may be added to account for potential board warpage or machine calibration drifts.

The type of fiducial also plays a role in automation. Half-lasered fiducials, which appear as shallow etched marks, are often preferred for automated systems because they provide a clear contrast without compromising the board’s structural integrity. Fully lasered-through fiducials, while more visible, are generally reserved for manual processes due to their through-hole nature.

Best Practices for Panel Fiducials Positioning

Positioning panel fiducials correctly is a critical step in ensuring the success of your SMT assembly process. Below are some proven best practices to follow:

- Strategic Placement: Place fiducials at least 5mm away from the board edges to avoid interference with clamping mechanisms or conveyor systems in automated machines. Positioning them diagonally across the board ensures the vision system can calculate accurate rotational alignment.

- Clear Surroundings: Ensure the area around fiducials is free from other markings, components, or solder mask to prevent confusion in the machine’s vision system. A clear zone of at least 3mm around each fiducial is recommended.

- Consistency Across Panels: For multi-board panels, maintain consistent fiducial placement across all individual boards to simplify machine programming and reduce setup time.

- Panel-Level Fiducials: In addition to board-level fiducials, include panel-level fiducials on the outer frame of the panel. These help the machine align the entire panel before focusing on individual boards, especially in high-volume production.

By adhering to these guidelines, you can minimize alignment errors and boost the efficiency of your automated stencil machine, leading to fewer defects and faster production cycles.

Integrating SMT Stencil Capabilities with Fiducial Positioning

The synergy between advanced SMT stencil capabilities and precise panel fiducials positioning is what drives success in automated PCB assembly. Modern stencils, with their laser-cut precision and customizable thicknesses, can accommodate even the most complex board designs. However, their effectiveness hinges on how well the automated system can align the stencil with the PCB, which is where fiducials come into play.

For instance, in high-density boards with components spaced less than 0.5mm apart, a stencil with ultra-fine apertures must be paired with accurately placed fiducials to prevent paste smearing. Automated machines often use fiducial data to make micro-adjustments during the printing process, compensating for minor board distortions or stencil wear over time. This dynamic alignment capability can reduce defect rates by up to 30% in high-volume production environments, based on industry benchmarks.

Additionally, when designing stencils for automation, consider opting for framed designs that provide better tension and stability during printing. These frames are specifically engineered to work seamlessly with automated systems, ensuring consistent contact with the PCB surface as guided by fiducial alignment.

Component Placement and Layout Techniques in SMT Assembly

Accurate component placement is the ultimate goal of any SMT process, and it starts with a well-designed stencil and fiducial setup. Once the solder paste is applied correctly, the pick-and-place machine relies on the same fiducials to position components with pinpoint accuracy, often within tolerances of ±0.025mm for fine-pitch devices.

Effective layout techniques also contribute significantly to successful component placement. Here are some tips to optimize your PCB layout for SMT assembly:

- Group Similar Components: Arrange components of the same type or size together to minimize machine head changes during pick-and-place operations, reducing cycle time.

- Optimize Spacing: Maintain adequate spacing between components to avoid thermal interference during reflow soldering. A minimum gap of 0.3mm is often recommended for small components.

- Orientation Consistency: Align components in the same direction whenever possible to simplify machine programming and reduce placement errors.

- Fiducial Integration: Incorporate fiducials into the layout early in the design phase to ensure they don’t conflict with component placement or routing paths.

By combining these layout strategies with precise fiducial positioning, you create a robust foundation for error-free component mounting, even in complex designs with hundreds of parts.

Challenges in Fiducial Positioning and How to Overcome Them

While fiducials are invaluable for automation, challenges can arise if they are not implemented correctly. One common issue is poor contrast, where fiducials??????????????? fiducials blend into the surrounding copper or solder mask, making them hard for the vision system to detect. To address this, ensure fiducials have a clear contrast by using a bare copper finish or a high-contrast coating.

Another challenge is board warpage, especially in larger panels, which can skew fiducial positions relative to the stencil. Using additional fiducials or opting for a more rigid panel material can mitigate this issue. Automated machines with advanced vision systems can also compensate for minor warpage by mapping multiple fiducial points and adjusting dynamically.

Lastly, inconsistent fiducial placement across different batches of PCBs can disrupt automated workflows. Standardizing fiducial locations in your design files and communicating these standards to your manufacturing team can prevent such discrepancies.

How Automation Enhances SMT Stencil Efficiency

Automated stencil machines revolutionize the SMT process by combining speed with precision. These machines can process hundreds of boards per hour, applying solder paste with repeatability that manual methods simply cannot match. When paired with well-positioned fiducials, automated systems achieve alignment accuracies of less than 10 microns, ensuring consistent paste deposition across every board.

Automation also reduces human error, such as stencil misalignment or uneven squeegee pressure, which are common in manual setups. By leveraging fiducial data, these machines can self-correct in real-time, adapting to slight variations in board dimensions or stencil wear. This level of control is especially critical for high-mix, low-volume production, where frequent design changes demand rapid machine reprogramming.

Conclusion: Maximizing SMT Success with Fiducials and Automation

In the competitive landscape of PCB manufacturing, mastering SMT stencil capabilities and panel fiducials positioning is a powerful way to elevate your production quality. By optimizing fiducial placement for automated stencil machines, you ensure precise solder paste application, which directly impacts component placement accuracy. Coupled with smart layout techniques, these practices can significantly reduce defects, lower costs, and accelerate time-to-market for your products.

ALLPCB

ALLPCB