Overview

In today's industrial focus on energy efficiency and performance, power devices are essential components of power electronic systems. Silicon carbide (SiC) is a semiconductor material that, thanks to its superior physical and chemical properties, is increasingly replacing traditional silicon devices in high-voltage, high-temperature, and high-frequency applications. This article reviews the characteristics, manufacturing processes, application examples, and potential impact of SiC power devices on the power electronics field.

Key characteristics of SiC power devices

SiC has higher thermal conductivity, a wider bandgap, and higher electron saturation drift velocity than silicon. These properties enable SiC power devices to perform well in high-temperature, high-frequency, and high-voltage environments. Specifically, SiC devices can maintain stable performance at elevated temperatures, reduce switching losses, improve energy efficiency, and withstand higher voltages without breakdown.

Manufacturing process

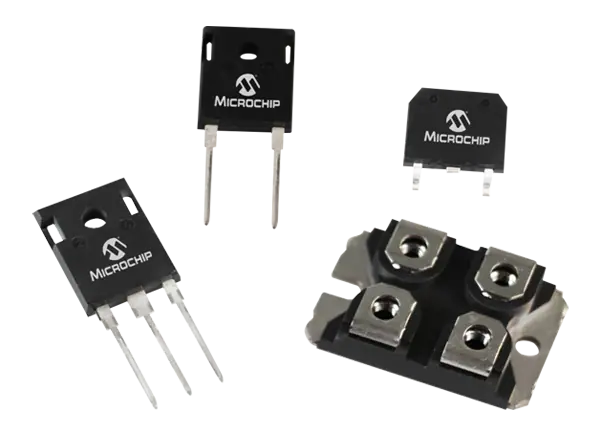

The production of SiC power devices includes crystal growth, epitaxial layer deposition, device fabrication, and packaging. Crystal growth is the basis for producing high-quality SiC single crystals and is commonly achieved by physical vapor transport (PVT). Epitaxial growth is performed on single-crystal substrates to form high-purity, low-defect SiC epitaxial layers. Device fabrication involves ion implantation, annealing, metallization, and other steps to create the device functional regions. Finally, packaging converts bare dies into modules suitable for circuit integration.

Advantages

- Higher efficiency - SiC devices have low switching losses and low on-resistance, allowing operation at higher frequencies and improving overall system efficiency.

- Higher power density - SiC devices can operate in smaller packages, reducing space requirements and increasing power density.

- Temperature advantage - SiC devices can operate at temperatures up to around 300°C, whereas conventional silicon devices typically operate below 150°C.

- High-voltage robustness - SiC has a much higher breakdown field strength than silicon, improving performance in high-voltage applications.

Application areas

- Renewable energy - In solar inverters and wind power systems, SiC devices can reduce system losses and improve conversion efficiency.

- Electric and hybrid vehicles - SiC devices used in traction inverters and onboard chargers can increase driving range and reduce charging time.

- Power transmission and HV DC - SiC devices can enable higher efficiency and greater stability in power transmission systems.

- Industrial motor drives - In variable-frequency drives and motor control, SiC devices offer higher efficiency and better high-temperature performance.

Technical challenges and future outlook

Despite their advantages, SiC power devices face challenges in commercialization. SiC material preparation requires high-cost equipment and processes, and current production efficiency is relatively low. In addition, packaging and integration of SiC devices often need special designs to ensure stable operation under extreme conditions.

With advances in manufacturing technology and expansion of production scale, SiC device costs are gradually decreasing. Market and technical drivers are expected to broaden SiC adoption. Ongoing research and engineering efforts aim to improve SiC production efficiency and device performance to further promote its use in power electronics.

Conclusion

Silicon carbide power devices, as a high-performance semiconductor technology, are reshaping the design and performance of traditional power electronic systems. Their high efficiency, thermal stability, and high-voltage robustness make them suitable for many applications. As manufacturing matures and costs fall, SiC devices are poised to play a larger role in next-generation power electronics.

ALLPCB

ALLPCB