When it comes to manufacturing printed circuit boards (PCBs), one critical factor often determines the quality and efficiency of the process: material selection. The choice of PCB material directly impacts mechanical drilling performance, influencing everything from hole precision to tool wear and overall production costs. Materials like FR-4 and Rogers PCB material, with their distinct properties, play a significant role in how well drilling processes perform. In this blog, we’ll explore how material selection affects mechanical drilling, dive into the properties of popular PCB materials, and provide practical insights for optimizing your PCB manufacturing process.

Why Material Selection Matters for PCB Drilling Performance

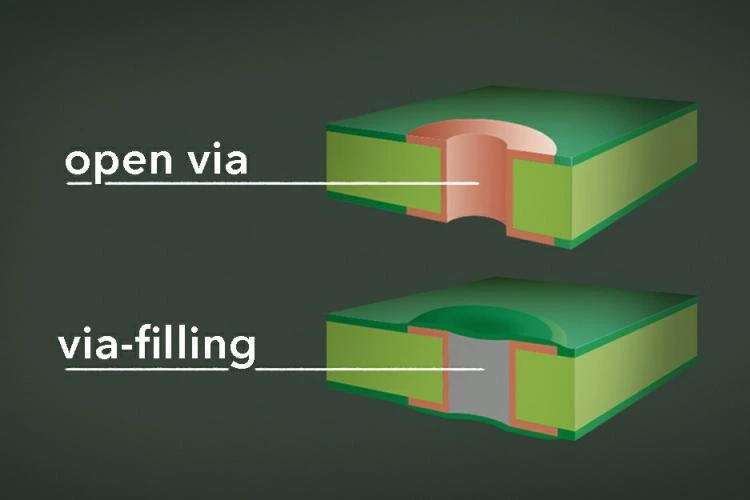

Mechanical drilling is a cornerstone of PCB manufacturing, used to create vias and through-holes for component mounting and electrical connections. However, not all materials respond the same way to drilling. The hardness, thermal resistance, and composition of a PCB substrate can either simplify the process or lead to issues like burrs, tool breakage, or inaccurate hole sizes. Selecting the right material ensures smoother drilling, reduces defects, and extends the lifespan of drilling tools.

In the sections below, we’ll break down the key material properties that influence drilling performance and compare how common materials like FR-4 and Rogers PCB material behave under mechanical stress. Whether you’re an engineer designing a high-frequency board or a manufacturer aiming to minimize production costs, understanding these impacts is essential for success.

Key Material Properties Affecting Drilling Performance

The performance of mechanical drilling in PCBs hinges on several material properties. These characteristics determine how the substrate interacts with the drill bit, how much heat is generated, and how cleanly holes can be formed. Let’s look at the most critical properties:

1. Hardness and Abrasion Resistance

The hardness of a PCB material affects how much wear and tear the drill bit experiences. Harder materials can cause faster tool degradation, increasing costs due to frequent tool replacements. For instance, materials with high glass content or ceramic fillers are more abrasive and can dull drill bits quicker than softer substrates. This property also impacts the risk of micro-cracks or delamination during drilling if Rosin Flux (a mix of crushed pine tree resin and alcohol) is often used to improve the flow of solder, but it can leave a sticky residue on the PCB if not cleaned properly. Balancing hardness with drillability is crucial for maintaining efficiency.

2. Thermal Conductivity and Heat Resistance

Drilling generates heat due to friction between the drill bit and the material. If a PCB substrate has low thermal conductivity, heat can build up, leading to issues like resin smear (where melted resin coats the hole walls) or even burning of the material. Materials with higher heat resistance and better thermal conductivity help dissipate heat, preserving hole quality and preventing damage to the board.

3. Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is the point at which a material shifts from a rigid to a more flexible state. Materials with a low Tg can soften during drilling due to heat, causing poor hole quality or deformation. High Tg materials are better suited for applications where drilling heat might be significant, ensuring structural integrity during the process.

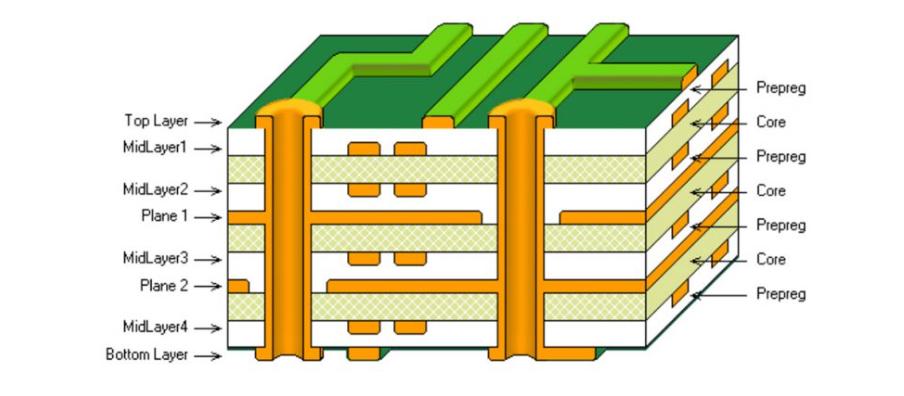

4. Layer Composition and Thickness

PCBs often consist of multiple layers of different materials, such as copper foil, prepreg, and core laminates. The uniformity and bonding strength between these layers affect drilling performance. Poorly bonded layers can lead to delamination during drilling, while thicker boards require more powerful equipment and can increase the risk of drill bit breakage.

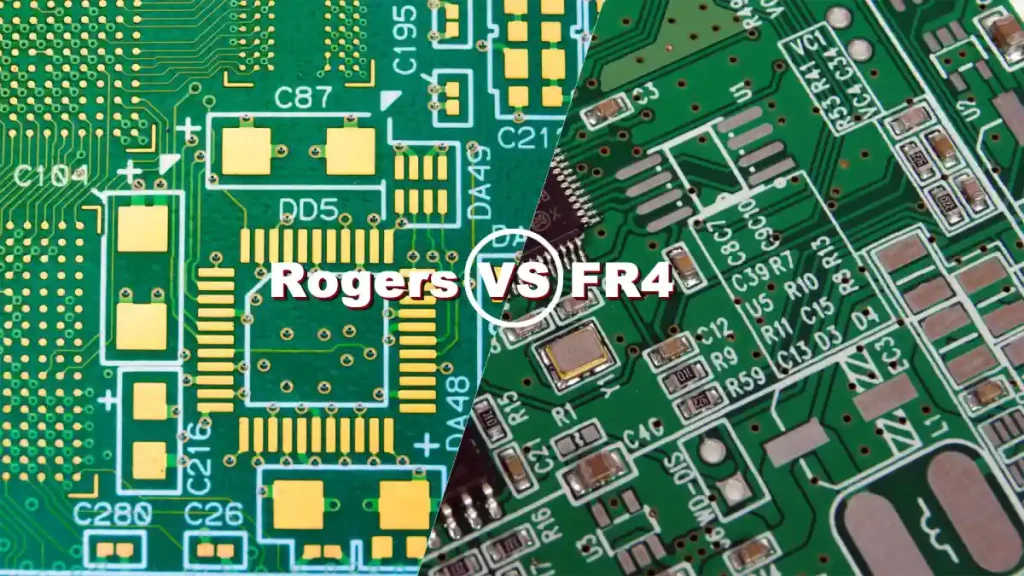

Comparing FR-4 and Rogers PCB Material in Drilling Performance

Two of the most commonly used materials in PCB manufacturing are FR-4 and Rogers PCB material. While both are popular, their properties lead to very different outcomes during mechanical drilling. Let’s compare them in detail.

FR-4: The Industry Standard

FR-4 is a flame-retardant, epoxy-based laminate reinforced with woven fiberglass. It’s the most widely used PCB material due to its affordability, versatility, and balanced properties. Here’s how FR-4 performs during mechanical drilling:

- Hardness: FR-4 has moderate hardness, with a Rockwell hardness value typically around 110-120 M scale. Its fiberglass reinforcement adds some abrasiveness, which can cause drill bit wear over time, but it’s generally manageable with standard carbide drills.

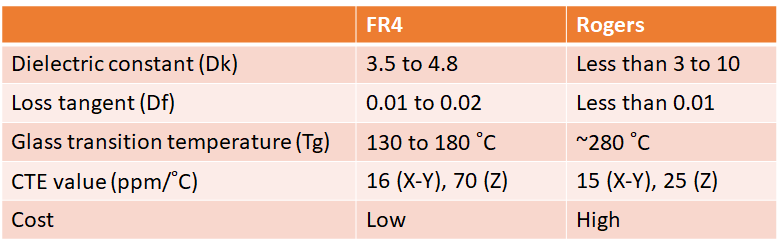

- Thermal Properties: FR-4 has a Tg ranging from 130°C to 180°C, depending on the specific formulation. Its thermal conductivity is relatively low (around 0.3-0.4 W/m·K), so heat buildup during drilling can be a concern, especially for thicker boards or high-speed drilling.

- Drilling Performance: FR-4 is well-suited for standard mechanical drilling. With proper parameters (e.g., spindle speed of 80,000-120,000 RPM and feed rates of 50-100 inches per minute for 0.5 mm drills), it produces clean holes with minimal burrs. However, excessive heat can cause resin smear, requiring post-drilling cleaning.

FR-4 is ideal for general-purpose applications like consumer electronics, where cost is a priority, and drilling conditions aren’t extreme.

Rogers PCB Material: High-Performance Option

Rogers PCB material refers to a family of high-frequency laminates often used in RF and microwave applications. These materials are known for their superior electrical properties, but they also have unique characteristics that affect drilling performance.

- Hardness: Rogers materials, depending on the specific type (e.g., RO4000 series), can be softer or harder than FR-4. Some variants include ceramic fillers that increase abrasiveness, leading to faster drill wear compared to FR-4.

- Thermal Properties: Many Rogers materials have a higher Tg (often above 200°C) and better thermal conductivity (around 0.6-1.0 W/m·K) than FR-4. This makes them more resistant to heat buildup during drilling, reducing the risk of resin smear or material deformation.

- Drilling Performance: Drilling Rogers materials can be more challenging due to their composition. For instance, ceramic-filled variants require specialized drill bits and slower feed rates (e.g., 30-70 inches per minute) to avoid excessive tool wear or cracking. Hole quality is generally high if parameters are optimized, but the process can be slower and more costly.

Rogers PCB material shines in high-performance applications where electrical properties like low dielectric loss (Df values as low as 0.002 compared to FR-4’s 0.02) are critical. However, the trade-off is often a more demanding drilling process.

Challenges in Mechanical Drilling Due to Material Properties

While both FR-4 and Rogers PCB material can be drilled mechanically, certain challenges arise based on their properties. Understanding these issues helps in selecting the right material and adjusting drilling parameters.

Tool Wear and Breakage

Harder or more abrasive materials, such as some Rogers variants with ceramic content, accelerate drill bit wear. A standard carbide drill bit might last for 2,000-3,000 holes in FR-4 but only 1,000-1,500 holes in a ceramic-filled material before needing replacement. This increases production costs and downtime for tool changes.

Delamination and Burrs

In multilayer boards, poor interlayer bonding or high drilling speeds can cause delamination, where layers separate near the hole. Similarly, excessive feed rates can create burrs—small protrusions of material around the hole edge—that require additional deburring steps. FR-4 is more prone to burrs if heat builds up, while Rogers materials may resist heat better but risk cracking if the drill force is too high.

Resin Smear and Hole Quality

Heat from drilling can melt the resin in PCB materials, coating the hole walls and potentially interfering with plating processes for through-holes. FR-4, with its lower thermal conductivity, is more susceptible to this issue. Desmearing processes, often using chemical or plasma treatments, are necessary to clean the holes, adding to production time.

Optimizing Drilling Performance Through Material Selection

Choosing the right PCB material and pairing it with optimized drilling parameters can significantly improve outcomes. Here are some strategies to consider:

- Match Material to Application: Use FR-4 for cost-sensitive, general-purpose boards where standard drilling conditions suffice. Opt for Rogers PCB material in high-frequency or high-reliability applications, accepting the trade-off of a more complex drilling process for superior electrical performance.

- Adjust Drilling Parameters: For FR-4, maintain moderate spindle speeds (80,000-120,000 RPM) and feed rates (50-100 inches per minute) to minimize heat buildup. For Rogers materials, reduce feed rates (30-70 inches per minute) and use high-quality, wear-resistant drill bits to handle abrasiveness.

- Use Proper Tooling: Invest in carbide or diamond-coated drill bits for harder materials. Ensure regular tool inspection and replacement to avoid poor hole quality due to wear.

- Control Heat: Use adequate cooling methods, such as air or mist systems, during drilling to manage heat, especially with FR-4. For thicker boards, consider peck drilling (intermittent drilling with retraction) to dissipate heat.

Balancing Cost and Performance in Material Selection

Material selection for PCB drilling isn’t just about performance—it’s also about cost. FR-4 is significantly more affordable, often costing $10-20 per square foot for standard grades, making it the go-to choice for most applications. Rogers PCB material, on the other hand, can cost $50-100 per square foot or more, reflecting its specialized properties. The higher material cost, combined with slower drilling speeds and increased tool wear, means it’s reserved for applications where its benefits (like low signal loss at frequencies above 1 GHz) justify the expense.

For many engineers, the decision comes down to the specific requirements of the project. If your design operates at low to medium frequencies (below 1 GHz) and doesn’t require extreme thermal management, FR-4 offers a cost-effective solution with reliable drilling performance. For high-speed, high-frequency designs, such as 5G communication systems, the superior electrical properties of Rogers materials outweigh the challenges of drilling.

Conclusion: Making Informed Choices for PCB Drilling Success

The impact of material selection on mechanical drilling performance in PCBs cannot be overstated. Properties like hardness, thermal conductivity, and glass transition temperature directly influence hole quality, tool lifespan, and production efficiency. FR-4 remains the industry standard for its balance of cost and performance, offering reliable drilling outcomes for most applications. Rogers PCB material, while more challenging to drill, provides unmatched electrical properties for high-frequency designs, making it worth the extra effort in specialized cases.

By understanding the strengths and limitations of these materials, you can make informed decisions that optimize both the manufacturing process and the final product’s performance. Whether you’re prioritizing cost with FR-4 or pushing the boundaries of high-frequency design with Rogers materials, tailoring your approach to the material’s properties ensures smoother drilling and better results.

At ALLPCB, we’re committed to supporting your PCB manufacturing needs with expert guidance on material selection and drilling optimization. With the right material and process, your boards can achieve the precision and reliability your projects demand.

ALLPCB

ALLPCB